Product Description

Adjustable Bevel Gear Worm Screw Jack with Motor High Quality China Factory Brand

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Stainless Steel |

|---|---|

| Type: | Round Head |

| Groove: | Cross |

| Connection: | Hinged Bolts |

| Head Style: | Square |

| Standard: | DIN, GB, ANSI, BSW, JIS, GOST |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can worm screws be used for high torque applications?

Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for applications that require high torque output. Here are some key points to consider regarding the use of worm screws in high torque applications:

- Gear Reduction: One of the primary advantages of a worm screw mechanism is its ability to provide a significant gear reduction in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio, which results in a lower output speed and higher output torque. This gear reduction capability allows worm screws to generate and transmit substantial torque, making them well-suited for high torque applications.

- Efficiency: While worm screws can provide high torque output, it’s important to consider the mechanical efficiency of the system. The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. It’s crucial to ensure that the efficiency of the worm screw mechanism meets the requirements of the specific high torque application.

- Load Holding: Another advantage of worm screws is their self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel, which provides resistance against backward rotation. This self-locking feature allows worm screws to hold loads in a fixed position without the need for additional braking mechanisms. In high torque applications where load holding is required, worm screws can provide reliable and secure positioning.

- Material Selection: The materials used for the worm screw and worm wheel should be carefully selected to withstand high torque loads. Both components should have sufficient strength and wear resistance to handle the transmitted torque without deformation or premature failure. Depending on the specific application requirements, materials such as hardened steel, bronze, or other alloys may be chosen to ensure the durability and performance of the worm screw assembly.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of a worm screw mechanism, especially in high torque applications. Adequate lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, ensuring efficient torque transfer. Regular maintenance, including monitoring lubricant levels and replenishing or replacing the lubricant as needed, is essential to maintain optimal performance and prevent premature wear or failure.

Overall, worm screws can be effectively used in high torque applications, thanks to their gear reduction capabilities, load-holding properties, and efficient torque transmission. However, it’s important to carefully consider factors such as mechanical efficiency, material selection, lubrication, and maintenance to ensure that the worm screw mechanism can meet the specific requirements and demands of the high torque application.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

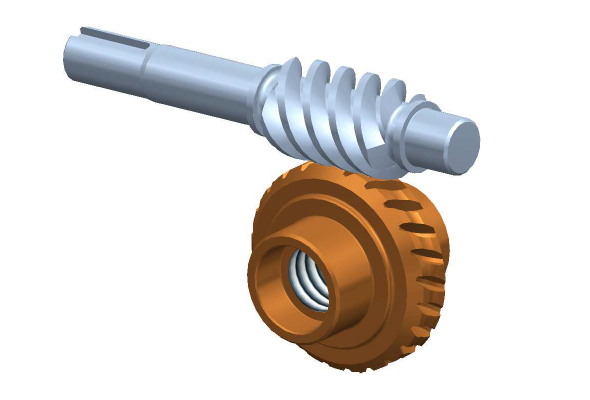

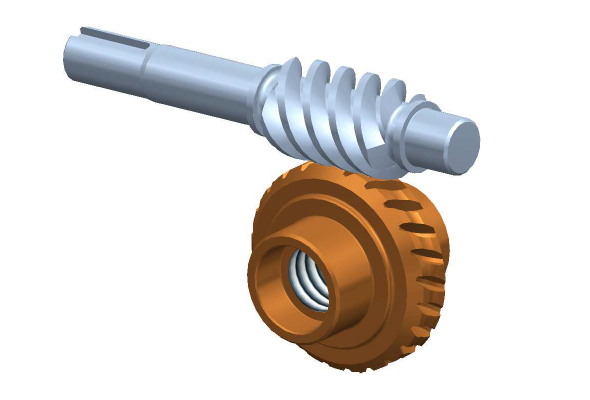

How does a worm screw mechanism work?

A worm screw mechanism, also known as a worm gear mechanism, is a type of power transmission system that consists of a worm screw and a worm wheel. It is designed to transmit motion and power between non-parallel shafts. The mechanism works based on the interaction between the helical threads of the worm screw and the teeth of the worm wheel. Here’s a detailed explanation of how a worm screw mechanism works:

- Structure: The worm screw is a cylindrical shaft with a helical thread wrapped around it, resembling a screw. The worm wheel, also known as a worm gear, is a gear with teeth that mesh with the threads of the worm screw. The orientation of the worm screw and the worm wheel is such that the axes of rotation are perpendicular to each other.

- Motion Transmission: When the worm screw is rotated, its helical threads engage with the teeth of the worm wheel. As the worm screw rotates, it drives the worm wheel to rotate as well. The helical shape of the worm screw and the teeth of the worm wheel allow for motion transmission perpendicular to the axis of the worm screw.

- Gear Reduction: One of the key characteristics of a worm screw mechanism is its ability to provide a significant gear reduction. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a substantial rotation of the worm wheel. The gear reduction enables the worm screw mechanism to generate high torque output at the worm wheel.

- Self-Locking: A notable feature of the worm screw mechanism is its self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel. This means that the worm wheel cannot easily rotate the worm screw. Instead, the worm screw tends to hold its position without the need for additional braking mechanisms. The self-locking feature makes the worm screw mechanism suitable for applications that require holding loads in a fixed position.

- Efficiency and Backlash: The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. Additionally, worm screw mechanisms may exhibit a certain amount of backlash, which refers to the slight play or clearance between the threads and teeth. Backlash can affect precision and introduce a small amount of lost motion in the system.

- Applications: Worm screw mechanisms find applications in various industries and machinery where motion transmission at right angles and high gear reduction ratios are required. Common applications include conveyor systems, lifting mechanisms, winches, automotive steering systems, robotics, and machine tools.

The worm screw mechanism offers a unique combination of motion transmission, gear reduction, and self-locking capabilities, making it suitable for specific applications where precise control, high torque output, and the ability to hold loads are essential.

editor by CX 2024-01-17

China wholesaler Adjustable Bevel Gear Worm Screw Jack with Motor High Quality China Factory Brand

Product Description

Adjustable Bevel Gear Worm Screw Jack with Motor High Quality China Factory Brand

| Material: | Stainless Steel |

|---|---|

| Type: | Round Head |

| Groove: | Cross |

| Connection: | Hinged Bolts |

| Head Style: | Square |

| Standard: | DIN, GB, ANSI, BSW, JIS, GOST |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can worm screws be used for high torque applications?

Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for applications that require high torque output. Here are some key points to consider regarding the use of worm screws in high torque applications:

- Gear Reduction: One of the primary advantages of a worm screw mechanism is its ability to provide a significant gear reduction in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio, which results in a lower output speed and higher output torque. This gear reduction capability allows worm screws to generate and transmit substantial torque, making them well-suited for high torque applications.

- Efficiency: While worm screws can provide high torque output, it’s important to consider the mechanical efficiency of the system. The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. It’s crucial to ensure that the efficiency of the worm screw mechanism meets the requirements of the specific high torque application.

- Load Holding: Another advantage of worm screws is their self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel, which provides resistance against backward rotation. This self-locking feature allows worm screws to hold loads in a fixed position without the need for additional braking mechanisms. In high torque applications where load holding is required, worm screws can provide reliable and secure positioning.

- Material Selection: The materials used for the worm screw and worm wheel should be carefully selected to withstand high torque loads. Both components should have sufficient strength and wear resistance to handle the transmitted torque without deformation or premature failure. Depending on the specific application requirements, materials such as hardened steel, bronze, or other alloys may be chosen to ensure the durability and performance of the worm screw assembly.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of a worm screw mechanism, especially in high torque applications. Adequate lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, ensuring efficient torque transfer. Regular maintenance, including monitoring lubricant levels and replenishing or replacing the lubricant as needed, is essential to maintain optimal performance and prevent premature wear or failure.

Overall, worm screws can be effectively used in high torque applications, thanks to their gear reduction capabilities, load-holding properties, and efficient torque transmission. However, it’s important to carefully consider factors such as mechanical efficiency, material selection, lubrication, and maintenance to ensure that the worm screw mechanism can meet the specific requirements and demands of the high torque application.

How does the pitch of a worm screw affect its performance?

The pitch of a worm screw plays a crucial role in determining its performance characteristics and capabilities. The pitch refers to the axial distance between consecutive threads on the worm screw. Here’s how the pitch of a worm screw affects its performance:

- Speed and Efficiency: The pitch of a worm screw directly influences the speed and efficiency of the worm gear system. A smaller pitch, which means a finer thread, results in a higher gear ratio and slower output speed. Conversely, a larger pitch, or coarser thread, leads to a lower gear ratio and faster output speed. This relationship between pitch and speed allows for speed reduction or multiplication in mechanical power transmission systems.

- Load Capacity: The pitch of a worm screw also affects its load-carrying capacity. A finer pitch tends to distribute the load over more threads, resulting in a larger contact area between the worm screw and the worm wheel. This increased contact area improves load distribution and allows for higher load capacity. Coarser pitches, on the other hand, may have a reduced contact area, which can limit the load-carrying capability of the worm gear system.

- Backlash: Backlash is the clearance or play between the threads of the worm screw and the teeth of the worm wheel. The pitch of a worm screw influences the amount of backlash present in the system. A finer pitch generally results in lower backlash due to the smaller clearance between the threads and the teeth. In contrast, coarser pitches may have increased backlash, which can negatively impact the system’s accuracy, precision, and responsiveness.

- Efficiency and Heat Generation: The pitch of a worm screw affects the overall efficiency of the worm gear system. Finer pitches tend to have higher efficiency due to reduced sliding friction between the threads and the teeth. This reduced friction results in less heat generation, contributing to higher overall system efficiency. Coarser pitches, on the other hand, may exhibit increased sliding friction, leading to higher energy losses and heat generation.

- Manufacturing and Design Considerations: The pitch of a worm screw also influences the manufacturing process and design considerations. Finer pitches generally require more precise machining or grinding processes to achieve the desired thread geometry. Coarser pitches, on the other hand, may offer advantages in terms of ease of manufacturing and reduced sensitivity to manufacturing tolerances. The selection of the optimal pitch depends on factors such as the desired gear ratio, load requirements, desired efficiency, and manufacturing capabilities.

It’s important to note that the pitch of a worm screw is typically specified by the manufacturer and should be chosen carefully based on the specific application requirements. Consulting with experts or engineers familiar with worm gear systems can help in selecting the appropriate pitch to achieve the desired performance and functionality.

How do you calculate the gear ratio for a worm screw and gear setup?

In a worm screw and gear setup, the gear ratio is determined by the number of teeth on the worm wheel (gear) and the number of threads on the worm screw. The gear ratio represents the relationship between the rotational speed of the worm screw and the resulting rotational speed of the worm wheel. The formula to calculate the gear ratio is as follows:

Gear Ratio = Number of Teeth on Worm Wheel / Number of Threads on Worm Screw

Here’s a step-by-step process to calculate the gear ratio:

- Count the number of teeth on the worm wheel. This can be done by visually inspecting the gear or referring to its specifications.

- Count the number of threads on the worm screw. The threads refer to the number of complete turns or helical grooves wrapped around the cylindrical body of the worm screw.

- Divide the number of teeth on the worm wheel by the number of threads on the worm screw.

- The result of the division is the gear ratio. It represents the number of revolutions of the worm screw required to complete one revolution of the worm wheel.

For example, let’s say the worm wheel has 40 teeth, and the worm screw has 2 threads. Using the formula, we can calculate the gear ratio as follows:

Gear Ratio = 40 teeth / 2 threads = 20

In this case, for every full revolution of the worm screw, the worm wheel will rotate 1/20th of a revolution. This indicates a significant speed reduction, resulting in high torque output at the worm wheel.

It’s important to note that the gear ratio calculated using this formula assumes an ideal scenario without considering factors like friction, efficiency losses, or the pitch diameter of the gears. In practical applications, these factors may affect the actual gear ratio and performance of the worm screw and gear setup.

editor by CX 2023-12-04

China 1400rpm Helical Gear Reducer,High Speed And Low Noise Nmrv Series Worm Gear Motor, NMRV 90 Gearboxes With Electric Motor double stage worm gearbox

2023-06-16

China Best price high torque 301 501 ratio speed reducer motor reduction worm gear gearbox for AC electric motor with Good quality

2023-06-15

China ACDC Motor RV Reductor Gear Box Right Angle Gearbox With 90 Degree Electric Motor worm gear box elecon

2023-06-14

China ACDC Motor RV Reductor Gear Box Right Angle Gearbox With 90 Degree Electric Motor with Great quality

2023-05-05

China A58SW-42BYS Dual Shaft Worm Gear Stepper Motor With Auto-lock double shaft stepper worm geared motor worm metal gearbox reducer worm gearbox china

2023-05-05

China 24v worm gear motor NMRV worm gear box reduction electric motor with Good quality

Applicable Industries: Accommodations, Garment Retailers, Constructing Material Stores, Manufacturing Plant, Machinery Mend Retailers, Foodstuff & Beverage Manufacturing unit, Farms, Cafe, Home Use, Retail, Food Shop, Printing Shops, Construction works , Power & Mining, Meals & Beverage Retailers, Advertising Firm

Tailored help: OEM

Gearing Arrangement: Worm

Output Torque: 12-3200Nm

Input Pace: dependent on motor

Output Speed: dependent on ratio

Identify: NMRV WORM GEARBOX

Product Quantity: NMRV571-NMRV150

Packing: Normal Packing

Guarantee: twelve Months

Colour: Blue or silvery

Output Form: Shaft Output

Certification: ISO9001

shaft: forty five# steel

worm: copper

Rated Electricity: .06-15KW

Packaging Particulars: According to the amount, the product design has diverse volume and bodyweight, UL Variety Rubber Tyre For Couplings and in accordance to the various mode of transportation, decide on wood box or carton packaging.

Item Overview NMRV worm equipment reducer – main components:NMRV571-NMRV90 reducer housing: aluminum alloy (body: 571-090)NMRV110-NMRV150 reducer housing cast iron (frame: one hundred ten-a hundred thirty)NMRV571-NMRV90 reducer: 20Cr, carburized and quenched, equipment floor hardness fifty six-62hrc, carburized layer thickness .3-.5mm after fine grindingNMRV571-NMRV90 reducer worm equipment: put on resistant tin bronze. Functions AT A Look 1. Large Quality Aluminum Alloy Casting/ Iron cast2. Hefty And Light3.No Rust4. Large Warmth Dissipation Efficiency5. Beautiful And Durable 6. Tiny Size7. It Can Adapt To All-Round Installation8. The Output Torque Is Large 9. Stable Transmission10. Minimal Noise11. Appropriate For Prolonged-Time period twelve. Ongoing Operate In13. Harsh Setting. NMRV with enter flange NMRV with output flange NMRV with output shaft Product Technical specs NMRV Design SelectThe electricity, speed ratio, output pace and torque of reducer are the important to decide on this merchandise, so we hope buyers can offer us with these parameters as significantly as possible. If you are not confident about the earlier mentioned parameters, please notify us your requirements, and we will select the very best design for you. Solution CONFIGURATION Domestic bearing with pure copper equipment New aluminum and iron scenario can be give New spare Equivalent Goods Business Packing & Supply Transport Sort:We will suggest 3 modes of transportation for buyers:SEA,Teach and AIR. In accordance to the various modes of transportation, we will choose standard export picket cases or cartons for packaging. In accordance to the bodyweight and quantity of items,we will also select distinct modes of transportation. You should Get in touch with US ABOUT THE FREIGHT! 80 sprockets chain, conveyor areas !!!! FAQ Q1: Are you a buying and selling organization or a maker ?A: We are a manufacturer in ZheJiang Province, China. Our firm owns the capability of manufacturing, processing, developing and R&D. We welcome your check out.Q2: How we decide on designs and specifications?A: According to the particular details of the requires from the component of enquiry, we will advise the products’ types CZPT synthesizing the aspects of area of items use, power, torque arm and ratio…Q3: How is your price? Can you offer you any price reduction?A: Our prices are often aggressive. If the consumer can place a huge purchase, we definitely will allow discount.Q4: How extended should I hold out for the comments soon after I ship the enquiry?A: We will reply as before long as achievable, twelve several hours at most.Q5: What is your product guarantee period?A: We have the certifications of ISO9001,CE, SGS.Q6: What industries are your gearboxes being employed?A: Our gearboxes are broadly applied to metallurgical equipment, Double chain sprockets 10B 12B miningequipment, automation products, food equipment, packaging tools, tobacco tools and so on.

What is a worm gear reducer gearbox?

A worm gear reducer gearbox is a mechanical device that uses a worm gear and a worm to reduce the speed of a rotating shaft. The gear reducer gearbox can increase the output torque of the engine according to the gear ratio. This type of gear reducer gearbox is characterized by its flexibility and compact size. It also increases the strength and efficiency of the drive.

Hollow shaft worm gear reducer gearbox

The hollow shaft worm gear reducer gearbox is an additional output shaft connecting various motors and other gearboxes. They can be installed horizontally or vertically. Depending on size and scale, they can be used with gearboxes from 4GN to 5GX.

Worm gear reducer gearboxes are usually used in combination with helical gear reducer gearboxes. The latter is mounted on the input side of the worm gear reducer gearbox and is a great way to reduce the speed of high output motors. The gear reducer gearbox has high efficiency, low speed operation, low noise, low vibration and low energy consumption.

Worm gear reducer gearboxes are made of hard steel or non-ferrous metals, increasing their efficiency. However, gears are not indestructible, and failure to keep running can cause the gear oil to rust or emulsify. This is due to moisture condensation that occurs during the operation and shutdown of the reducer gearbox. The assembly process and quality of the bearing are important factors to prevent condensation.

Hollow shaft worm gear reducer gearboxes can be used in a variety of applications. They are commonly used in machine tools, variable speed drives and automotive applications. However, they are not suitable for continuous operation. If you plan to use a hollow shaft worm gear reducer gearbox, be sure to choose the correct one according to your requirements.

Double throat worm gear

Worm gear reducer gearboxes use a worm gear as the input gear. An electric motor or sprocket drives the worm, which is supported by anti-friction roller bearings. Worm gears are prone to wear due to the high friction in the gear teeth. This leads to corrosion of the confinement surfaces of the gears.

The pitch diameter and working depth of the worm gear are important. The pitch circle diameter is the diameter of the imaginary circle in which the worm and the gear mesh. Working depth is the maximum amount of worm thread that extends into the backlash. Throat diameter is the diameter of the circle at the lowest point of the worm gear face.

When the friction angle between the worm and the gear exceeds the lead angle of the worm, the worm gear is self-locking. This feature is useful for lifting equipment, but may be detrimental to systems that require reverse sensitivity. In these systems, the self-locking ability of the gears is a key limitation.

The double throat worm gear provides the tightest connection between the worm and the gear. The worm gear must be installed correctly to ensure maximum efficiency. One way to install the worm gear assembly is through a keyway. The keyway prevents the shaft from rotating, which is critical for transmitting torque. Then attach the gear to the hub using the set screw.

The axial and circumferential pitch of the worm gear should match the pitch diameter of the larger gear. Single-throat worm gears are single-threaded, and double-throat worm gears are double-throat. A single thread design advances one tooth, while a double thread design advances two teeth. The number of threads should match the number of mating gears.

Self-locking function

One of the most prominent features of a worm reducer gearbox is its self-locking function, which prevents the input and output shafts from being interchanged. The self-locking function is ideal for industrial applications where large gear reduction ratios are required without enlarging the gear box.

The self-locking function of a worm reducer gearbox can be achieved by choosing the right type of worm gear. However, it should be noted that this feature is not available in all types of worm gear reducer gearboxes. Worm gears are self-locking only when a specific speed ratio is reached. When the speed ratio is too small, the self-locking function will not work effectively.

Self-locking status of a worm reducer gearbox is determined by the lead, pressure, and coefficient of friction. In the early twentieth century, cars had a tendency to pull the steering toward the side with a flat tire. A worm drive reduced this tendency by reducing frictional forces and transmitting steering force to the wheel, which aids in steering and reduces wear and tear.

A self-locking worm reducer gearbox is a simple-machine with low mechanical efficiency. It is self-locking when the work at one end is greater than the work at the other. If the mechanical efficiency of a worm reducer gearbox is less than 50%, the friction will result in losses. In addition, the self-locking function is not applicable when the drive is reversed. This characteristic makes self-locking worm gears ideal for hoisting and lowering applications.

Another feature of a worm reducer gearbox is its ability to reduce axially. Worm gears can be double-lead or single-lead, and it is possible to adjust their backlash to compensate for tooth wear.

Heat generated by worm gears

Worm gears generate considerable amounts of heat. It is essential to reduce this heat to improve the performance of the gears. This heat can be mitigated by designing the worms with smoother surfaces. In general, the speed at which worm gears mesh should be in the range of 20 to 24 rms.

There are many approaches for calculating worm gear efficiency. However, no other approach uses an automatic approach to building the thermal network. The other methods either abstractly investigate the gearbox as an isothermal system or build the TNM statically. This paper describes a new method for automatically calculating heat balance and efficiency for worm gears.

Heat generated by worm gears is a significant source of power loss. Worm gears are typically characterized by high sliding speeds in their tooth contacts, which causes high frictional heat and increased thermal stresses. As a result, accurate calculations are necessary to ensure optimal operation. In order to determine the efficiency of a gearbox system, manufacturers often use the simulation program WTplus to calculate heat loss and efficiency. The heat balance calculation is achieved by adding the no-load and load-dependent power losses of the gearbox.

Worm gears require a special type of lubricant. A synthetic oil that is non-magnetic and has a low friction coefficient is used. However, the oil is only one of the options for lubricating worm gears. In order to extend the life of worm gears, you should also consider adding a natural additive to the lubricant.

Worm gears can have a very high reduction ratio. They can achieve massive reductions with little effort, compared to conventional gearsets which require multiple reductions. Worm gears also have fewer moving parts and places for failure than conventional gears. One disadvantage of worm gears is that they are not reversible, which limits their efficiency.

Size of worm gear reducer gearbox

Worm gear reducer gearboxes can be used to decrease the speed of a rotating shaft. They are usually designed with two shafts at right angles. The worm wheel acts as both the pinion and rack. The central cross section forms the boundary between the advancing and receding sides of the worm gear.

The output gear of a worm gear reducer gearbox has a small diameter compared to the input gear. This allows for low-speed operation while producing a high-torque output. This makes worm gear reducer gearboxes great for space-saving applications. They also have low initial costs.

Worm gear reducer gearboxes are one of the most popular types of speed reducer gearboxes. They can be small and powerful and are often used in power transmission systems. These units can be used in elevators, conveyor belts, security gates, and medical equipment. Worm gearing is often found in small and large sized machines.

Worm gears can also be adjusted. A dual-lead worm gear has a different lead on the left and right tooth surfaces. This allows for axial movement of the worm and can also be adjusted to reduce backlash. A backlash adjustment may be necessary as the worm wears down. In some cases, this backlash can be adjusted by adjusting the center distance between the worm gear.

The size of worm gear reducer gearbox depends on its function. For example, if the worm gear is used to reduce the speed of an automobile, it should be a model that can be installed in a small car.

editor by Cx 2023-05-04

China Industrial Mechanical Transmission Nmrv Gear Motor Worm Gearbox with high quality

Product Description

Merchandise Description

Major Supplies:

one)housing:aluminium alloy ADC12(measurement 571-090) die forged iron HT200(dimension a hundred and ten-a hundred and fifty)

2)Worm:20Cr, ZI Involute profile carbonize&quencher warmth treatment make equipment floor hardness up to 56-sixty two HRC Soon after precision grinding, carburization layer’s thickness in between .3-.5mm.

three)Worm Wheel:wearable stannum alloy CuSn10-one

In depth Pictures

Mixture Alternatives:

Enter:with enter shaft, With sq. flange,With IEC common input flange

Output:with torque arm, output flange, solitary output shaft, double output shaft, plastic cover

Worm reducers are accessible with diffferent mixtures: NMRV+NMRV, NMRV+NRV, NMRV+Computer, NMRV+UDL, NMRV+MOTORS

Exploded Look at:

Product Parameters

| Outdated Model |

New Model | Ratio | Center Distance | Energy | Enter Dia. | Output Dia. | Output Torque | Fat |

| RV571 | 7.5~100 | 25mm | .06KW~.12KW | Φ9 | Φ11 | 21N.m | .7kgs | |

| RV030 | RW030 | seven.5~100 | 30mm | .06KW~.25KW | Φ9(Φ11) | Φ14 | 45N.m | one.2kgs |

| RV040 | RW040 | 7.5~one hundred | 40mm | .09KW~.55KW | Φ9(Φ11,Φ14) | Φ18(Φ19) | 84N.m | two.3kgs |

| RV050 | RW050 | 7.5~a hundred | 50mm | .12KW~1.5KW | Φ11(Φ14,Φ19) | Φ25(Φ24) | 160N.m | three.5kgs |

| RV063 | RW063 | 7.5~a hundred | 63mm | .18KW~2.2KW | Φ14(Φ19,Φ24) | Φ25(Φ28) | 230N.m | six.2kgs |

| RV075 | RW075 | 7.5~100 | 75mm | .25KW~4.0KW | Φ14(Φ19,Φ24,Φ28) | Φ28(Φ35) | 410N.m | 9.0kgs |

| RV090 | RW090 | seven.5~100 | 90mm | .37KW~4.0KW | Φ19(Φ24,Φ28) | Φ35(Φ38) | 725N.m | 13.0kgs |

| RV110 | RW110 | seven.5~one hundred | 110mm | .55KW~7.5KW | Φ19(Φ24,Φ28,Φ38) | Φ42 | 1050N.m | 35.0kgs |

| RV130 | RW130 | seven.5~a hundred | 130mm | .75KW~7.5KW | Φ24(Φ28,Φ38) | Φ45 | 1550N.m | forty eight.0kgs |

| RV150 | RW150 | 7.5~a hundred | 150mm | 2.2KW~15KW | Φ28(Φ38,Φ42) | Φ50 | 84.0kgs |

GMRV Define Dimension:

| GMRV | A | B | C | C1 | D(H8) | E(h8) | F | G | G1 | H | H1 | I | M | N | O | P | Q | R | S | T | BL | β | b | t | V |

| 030 | 80 | ninety seven | fifty four | forty four | fourteen | 55 | 32 | fifty six | 63 | 65 | 29 | 55 | forty | fifty seven | thirty | 75 | forty four | 6.5 | 21 | five.5 | M6*10(n=4) | 0° | five | sixteen.3 | 27 |

| 040 | one hundred | 121.5 | 70 | sixty | 18(19) | 60 | 43 | 71 | seventy eight | seventy five | 36.5 | 70 | fifty | seventy one.5 | 40 | 87 | fifty five | six.5 | 26 | six.five | M6*ten(n=4) | 45° | 6 | twenty.8(21.8) | 35 |

| 050 | 120 | a hundred and forty four | eighty | 70 | 25(24) | 70 | forty nine | 85 | 92 | eighty five | forty three.5 | 80 | sixty | 84 | 50 | a hundred | 64 | 8.5 | thirty | 7 | M8*twelve(n=4) | 45° | 8 | 28.3(27.3) | 40 |

| 063 | 144 | 174 | one hundred | 85 | 25(28) | 80 | sixty seven | 103 | 112 | 95 | 53 | 95 | 72 | 102 | 63 | 110 | 80 | eight.5 | 36 | 8 | M8*12(n=8) | 45° | 8 | 28.3(31.3) | 50 |

| 075 | 172 | 205 | 120 | ninety | 28(35) | 95 | seventy two | 112 | a hundred and twenty | one hundred fifteen | fifty seven | 112.5 | 86 | 119 | 75 | a hundred and forty | 93 | 11 | 40 | ten | M8*14(n=8) | 45° | 8(10) | 31.3(38.3) | 60 |

| 090 | 206 | 238 | one hundred forty | one hundred | 35(38) | 110 | 74 | 130 | 140 | 130 | 67 | 129.5 | 103 | 135 | ninety | one hundred sixty | 102 | 13 | forty five | eleven | M10*16(n=8) | 45° | ten | 38.3(41.3) | 70 |

| 110 | 255 | 295 | 170 | one hundred fifteen | 42 | a hundred thirty | – | a hundred and forty four | 155 | 165 | 74 | one hundred sixty | 127.five | 167.5 | one hundred ten | 200 | one hundred twenty five | fourteen | fifty | fourteen | M10*eighteen(n=8) | 45° | 12 | forty five.3 | eighty five |

| one hundred thirty | 293 | 335 | two hundred | a hundred and twenty | forty five | 180 | – | a hundred and fifty five | a hundred and seventy | 215 | 81 | 179 | 146.five | 187.5 | 130 | 250 | a hundred and forty | sixteen | 60 | fifteen | M12*twenty(n=8) | 45° | 14 | 48.8 | a hundred |

| a hundred and fifty | 340 | 400 | 240 | a hundred forty five | fifty | 180 | – | 185 | 200 | 215 | ninety six | 210 | a hundred and seventy | 230 | one hundred fifty | 250 | a hundred and eighty | 18 | seventy two.5 | 18 | M12*22(n=8) | 45° | fourteen | 53.8 | 120 |

Firm Profile

About CZPT Transmission:

We are a professional reducer manufacturer found in HangZhou, ZHangZhoug province.

Our foremost goods is full variety of RV571-150 worm reducers , also supplied GKM hypoid helical gearbox, GRC inline helical gearbox, Pc units, UDL Variators and AC Motors, G3 helical equipment motor.

Merchandise are extensively used for programs these kinds of as: foodstuffs, ceramics, packing, chemical compounds, pharmacy, plastics, paper-making, building machinery, metallurgic mine, environmental safety engineering, and all types of automated lines, and assembly traces.

With quick shipping, superior soon after-sales services, superior producing facility, our goods sell well both at home and abroad. We have exported our reducers to Southeast Asia, Jap Europe and Middle East and so on.Our intention is to develop and innovate on basis of higher top quality, and develop a good popularity for reducers.

Packing information:Plastic Luggage+Cartons+Picket Situations , or on ask for

We take part Germany Hannver Exhibition-ZheJiang PTC Honest-Turkey Get Eurasia

Logistics

Right after Revenue Support

one.Routine maintenance Time and Guarantee:Inside 1 yr after getting goods.

2.Other Provider: Such as modeling variety manual, set up guide, and issue resolution guidebook, etc.

FAQ

one.Q:Can you make as for every customer drawing?

A: Sure, we supply custom-made service for clients appropriately. We can use customer’s nameplate for gearboxes.

two.Q:What is your phrases of payment ?

A: 30% deposit just before manufacturing,equilibrium T/T before shipping and delivery.

three.Q:Are you a trading firm or manufacturer?

A:We are a manufacurer with innovative products and knowledgeable staff.

four.Q:What is your generation capacity?

A:8000-9000 PCS/Month

five.Q:Cost-free sample is accessible or not?

A:Of course, we can source cost-free sample if buyer concur to shell out for the courier expense

6.Q:Do you have any certification?

A:Indeed, we have CE certification and SGS certificate report.

Contact info:

Ms Lingel Pan

For any concerns just come to feel free of charge ton make contact with me. Numerous thanks for your type focus to our company!

|

US $35-220 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery, Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Right Angle |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

###

| Samples: |

US$ 35/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Old Model |

New Model | Ratio | Center Distance | Power | Input Dia. | Output Dia. | Output Torque | Weight |

| RV025 | 7.5~100 | 25mm | 0.06KW~0.12KW | Φ9 | Φ11 | 21N.m | 0.7kgs | |

| RV030 | RW030 | 7.5~100 | 30mm | 0.06KW~0.25KW | Φ9(Φ11) | Φ14 | 45N.m | 1.2kgs |

| RV040 | RW040 | 7.5~100 | 40mm | 0.09KW~0.55KW | Φ9(Φ11,Φ14) | Φ18(Φ19) | 84N.m | 2.3kgs |

| RV050 | RW050 | 7.5~100 | 50mm | 0.12KW~1.5KW | Φ11(Φ14,Φ19) | Φ25(Φ24) | 160N.m | 3.5kgs |

| RV063 | RW063 | 7.5~100 | 63mm | 0.18KW~2.2KW | Φ14(Φ19,Φ24) | Φ25(Φ28) | 230N.m | 6.2kgs |

| RV075 | RW075 | 7.5~100 | 75mm | 0.25KW~4.0KW | Φ14(Φ19,Φ24,Φ28) | Φ28(Φ35) | 410N.m | 9.0kgs |

| RV090 | RW090 | 7.5~100 | 90mm | 0.37KW~4.0KW | Φ19(Φ24,Φ28) | Φ35(Φ38) | 725N.m | 13.0kgs |

| RV110 | RW110 | 7.5~100 | 110mm | 0.55KW~7.5KW | Φ19(Φ24,Φ28,Φ38) | Φ42 | 1050N.m | 35.0kgs |

| RV130 | RW130 | 7.5~100 | 130mm | 0.75KW~7.5KW | Φ24(Φ28,Φ38) | Φ45 | 1550N.m | 48.0kgs |

| RV150 | RW150 | 7.5~100 | 150mm | 2.2KW~15KW | Φ28(Φ38,Φ42) | Φ50 | 84.0kgs |

###

| GMRV | A | B | C | C1 | D(H8) | E(h8) | F | G | G1 | H | H1 | I | M | N | O | P | Q | R | S | T | BL | β | b | t | V |

| 030 | 80 | 97 | 54 | 44 | 14 | 55 | 32 | 56 | 63 | 65 | 29 | 55 | 40 | 57 | 30 | 75 | 44 | 6.5 | 21 | 5.5 | M6*10(n=4) | 0° | 5 | 16.3 | 27 |

| 040 | 100 | 121.5 | 70 | 60 | 18(19) | 60 | 43 | 71 | 78 | 75 | 36.5 | 70 | 50 | 71.5 | 40 | 87 | 55 | 6.5 | 26 | 6.5 | M6*10(n=4) | 45° | 6 | 20.8(21.8) | 35 |

| 050 | 120 | 144 | 80 | 70 | 25(24) | 70 | 49 | 85 | 92 | 85 | 43.5 | 80 | 60 | 84 | 50 | 100 | 64 | 8.5 | 30 | 7 | M8*12(n=4) | 45° | 8 | 28.3(27.3) | 40 |

| 063 | 144 | 174 | 100 | 85 | 25(28) | 80 | 67 | 103 | 112 | 95 | 53 | 95 | 72 | 102 | 63 | 110 | 80 | 8.5 | 36 | 8 | M8*12(n=8) | 45° | 8 | 28.3(31.3) | 50 |

| 075 | 172 | 205 | 120 | 90 | 28(35) | 95 | 72 | 112 | 120 | 115 | 57 | 112.5 | 86 | 119 | 75 | 140 | 93 | 11 | 40 | 10 | M8*14(n=8) | 45° | 8(10) | 31.3(38.3) | 60 |

| 090 | 206 | 238 | 140 | 100 | 35(38) | 110 | 74 | 130 | 140 | 130 | 67 | 129.5 | 103 | 135 | 90 | 160 | 102 | 13 | 45 | 11 | M10*16(n=8) | 45° | 10 | 38.3(41.3) | 70 |

| 110 | 255 | 295 | 170 | 115 | 42 | 130 | – | 144 | 155 | 165 | 74 | 160 | 127.5 | 167.5 | 110 | 200 | 125 | 14 | 50 | 14 | M10*18(n=8) | 45° | 12 | 45.3 | 85 |

| 130 | 293 | 335 | 200 | 120 | 45 | 180 | – | 155 | 170 | 215 | 81 | 179 | 146.5 | 187.5 | 130 | 250 | 140 | 16 | 60 | 15 | M12*20(n=8) | 45° | 14 | 48.8 | 100 |

| 150 | 340 | 400 | 240 | 145 | 50 | 180 | – | 185 | 200 | 215 | 96 | 210 | 170 | 230 | 150 | 250 | 180 | 18 | 72.5 | 18 | M12*22(n=8) | 45° | 14 | 53.8 | 120 |

|

US $35-220 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery, Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Right Angle |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

###

| Samples: |

US$ 35/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Old Model |

New Model | Ratio | Center Distance | Power | Input Dia. | Output Dia. | Output Torque | Weight |

| RV025 | 7.5~100 | 25mm | 0.06KW~0.12KW | Φ9 | Φ11 | 21N.m | 0.7kgs | |

| RV030 | RW030 | 7.5~100 | 30mm | 0.06KW~0.25KW | Φ9(Φ11) | Φ14 | 45N.m | 1.2kgs |

| RV040 | RW040 | 7.5~100 | 40mm | 0.09KW~0.55KW | Φ9(Φ11,Φ14) | Φ18(Φ19) | 84N.m | 2.3kgs |

| RV050 | RW050 | 7.5~100 | 50mm | 0.12KW~1.5KW | Φ11(Φ14,Φ19) | Φ25(Φ24) | 160N.m | 3.5kgs |

| RV063 | RW063 | 7.5~100 | 63mm | 0.18KW~2.2KW | Φ14(Φ19,Φ24) | Φ25(Φ28) | 230N.m | 6.2kgs |

| RV075 | RW075 | 7.5~100 | 75mm | 0.25KW~4.0KW | Φ14(Φ19,Φ24,Φ28) | Φ28(Φ35) | 410N.m | 9.0kgs |

| RV090 | RW090 | 7.5~100 | 90mm | 0.37KW~4.0KW | Φ19(Φ24,Φ28) | Φ35(Φ38) | 725N.m | 13.0kgs |

| RV110 | RW110 | 7.5~100 | 110mm | 0.55KW~7.5KW | Φ19(Φ24,Φ28,Φ38) | Φ42 | 1050N.m | 35.0kgs |

| RV130 | RW130 | 7.5~100 | 130mm | 0.75KW~7.5KW | Φ24(Φ28,Φ38) | Φ45 | 1550N.m | 48.0kgs |

| RV150 | RW150 | 7.5~100 | 150mm | 2.2KW~15KW | Φ28(Φ38,Φ42) | Φ50 | 84.0kgs |

###

| GMRV | A | B | C | C1 | D(H8) | E(h8) | F | G | G1 | H | H1 | I | M | N | O | P | Q | R | S | T | BL | β | b | t | V |

| 030 | 80 | 97 | 54 | 44 | 14 | 55 | 32 | 56 | 63 | 65 | 29 | 55 | 40 | 57 | 30 | 75 | 44 | 6.5 | 21 | 5.5 | M6*10(n=4) | 0° | 5 | 16.3 | 27 |

| 040 | 100 | 121.5 | 70 | 60 | 18(19) | 60 | 43 | 71 | 78 | 75 | 36.5 | 70 | 50 | 71.5 | 40 | 87 | 55 | 6.5 | 26 | 6.5 | M6*10(n=4) | 45° | 6 | 20.8(21.8) | 35 |

| 050 | 120 | 144 | 80 | 70 | 25(24) | 70 | 49 | 85 | 92 | 85 | 43.5 | 80 | 60 | 84 | 50 | 100 | 64 | 8.5 | 30 | 7 | M8*12(n=4) | 45° | 8 | 28.3(27.3) | 40 |

| 063 | 144 | 174 | 100 | 85 | 25(28) | 80 | 67 | 103 | 112 | 95 | 53 | 95 | 72 | 102 | 63 | 110 | 80 | 8.5 | 36 | 8 | M8*12(n=8) | 45° | 8 | 28.3(31.3) | 50 |

| 075 | 172 | 205 | 120 | 90 | 28(35) | 95 | 72 | 112 | 120 | 115 | 57 | 112.5 | 86 | 119 | 75 | 140 | 93 | 11 | 40 | 10 | M8*14(n=8) | 45° | 8(10) | 31.3(38.3) | 60 |

| 090 | 206 | 238 | 140 | 100 | 35(38) | 110 | 74 | 130 | 140 | 130 | 67 | 129.5 | 103 | 135 | 90 | 160 | 102 | 13 | 45 | 11 | M10*16(n=8) | 45° | 10 | 38.3(41.3) | 70 |

| 110 | 255 | 295 | 170 | 115 | 42 | 130 | – | 144 | 155 | 165 | 74 | 160 | 127.5 | 167.5 | 110 | 200 | 125 | 14 | 50 | 14 | M10*18(n=8) | 45° | 12 | 45.3 | 85 |

| 130 | 293 | 335 | 200 | 120 | 45 | 180 | – | 155 | 170 | 215 | 81 | 179 | 146.5 | 187.5 | 130 | 250 | 140 | 16 | 60 | 15 | M12*20(n=8) | 45° | 14 | 48.8 | 100 |

| 150 | 340 | 400 | 240 | 145 | 50 | 180 | – | 185 | 200 | 215 | 96 | 210 | 170 | 230 | 150 | 250 | 180 | 18 | 72.5 | 18 | M12*22(n=8) | 45° | 14 | 53.8 | 120 |

Worm gear reducer gearbox

Cheaper than planetary gearboxes In many cases, worm gear reducer gearboxes are a popular alternative to planetary gearboxes. A worm gear reducer gearbox is a mechanical device with vertical input and output shafts. This allows for very high reduction ratios. They are typically used in high-reduction situations such as machine tools.

Worm gears are cheaper than traditional gearboxes. They also have many benefits, including noise reduction. The output shaft of the worm gear reducer gearbox is almost 90 degrees from the motor input shaft, making it ideal for high-torque applications.

The worm gear reducer gearbox adopts an aluminum body, which is light in weight and high in operation efficiency. Additionally, they are available with hollow shafts and mounting flanges. In terms of initial cost, worm gear reducer gearboxes are cheaper than planetary gearboxes. In addition, they have better efficiency and longer service life.

Worm drives are also ideal for portable battery-powered lifting equipment. The high gear ratio of the worm gear ensures that it does not reverse drive. The worm gear has a spring-applied brake that holds the motor in place.

Planetary gearboxes are popular among industrial users. The efficiency of planetary gearboxes is important for practical applications.

The compact worm gear unit consists of a housing with an inner cavity. It has two side walls, one on either side of the front cover (13) and one on both sides of the rear cover (14). The front end cap is screwed onto the housing and the inner cavity is accessed through the rear end cap.

The compact worm gear unit can be configured to suit your application. They have many advantages, including saving space and increasing torque. The range includes single-envelope and double-envelope versions, available in a number of different power ratings. Additionally, they are IP65-rated, making them ideal for applications involving high radial or axial forces.

The compact worm reducer gearbox is a simple but effective worm drive. Its worm gear 16 meshes with the output shaft and rotates relatively stably. It also has a front-end cap and rear bearing. This enables the compact worm reducer gearbox to reduce vibration without damaging the output shaft.

Compact worm gear reducer gearboxes are ideal for many applications and offer high efficiency. The compact design means you can mount them on the motor’s flange or base. Its durable construction makes it ideal for a variety of industries. They are extremely durable and can handle high-pressure and washdown conditions. They also come standard with a synthetic shaft.

high efficiency

High-efficiency worm gear reducer gearboxes are ideal for applications that require precision, repeatability, and efficient performance. These reducer gearboxes are designed with state-of-the-art servo motor technology to provide tight integration and an angular backlash of less than two arc minutes. The reduction ratio can be lower if the application requires it.

Rising energy costs have led to an increased focus on the efficiency of drives. In response to this, manufacturers have increased the efficiency of worm gear reducer gearboxes through a number of technical improvements. By minimizing losses from rolling and sliding friction, worm gear reducer gearboxes are more efficient than their counterparts.

The high-efficiency worm reducer gearbox is simple in design and has the characteristics of a compact structure, high-speed ratio, low power consumption, and self-locking. Other advantages of these reducer gearboxes include low noise and long service life. Many also have built-in control systems that allow manual and remote adjustments. They also feature automatic shutdown protection and thermal protection.

High-efficiency worm reducer gearboxes can be used for mechanical acceleration. The input hypoid gear is usually made of steel, while the output hypoid gear is usually made of bronze. Bronze is a soft metal that is good at absorbing shock loads. However, bronze requires work hardening to achieve optimum hardness. For large worm gears, this process can take 300 to 550 hours.

low clearance

A low-clearance worm reducer gearbox is a device used to adjust the speed of a rotating shaft. It uses a worm gear consisting of two members. One worm is at one end of the shaft and the other is at the other end. Both worms are screwed into the synchronous drive structure.

Low clearance worm gear reducer gearboxes can be produced on conventional worm gear production lines without overlapping investments. These units are usually made of soft rubber. Also, they are relatively quiet in operation. These machines are designed so that they are suitable for use in elevators. The softer material in the worm gear also helps absorb shock loads.

The tooth profile of the worm gear is designed to change with the axial movement of the worm. Worms have thinner right teeth and thicker left teeth. As the worm moves to the right, its teeth mesh with the worm gear, reducing backlash.

There are many different types of worm gears. The design of gears depends on many factors, including backlash, thermal design, friction factors and lubrication. Worm gears are made of several different materials. Some different types of materials used in worm gears require special lubrication.

quieter

The quieter worm reducer gearbox is designed to reduce the noise level of the rotating gear motor. The device has more gear teeth in meshing contact with the gears, which helps it run more quietly. In addition to being quieter than other transmissions, it’s also less expensive than its counterparts.

Worm gearboxes can be used for different applications, but they are not as efficient as helical gearboxes. Worm reducer gearboxes are cheaper but less than 90% efficient. Higher gear ratios reduce efficiency, so worm gear reducer gearboxes are better suited for applications that require low-speed torque. The cost of buying a worm gearbox will depend on the horsepower and gear ratios required.

Worm reducer gearboxes are also more comfortable to use than planetary gearboxes. They don’t vibrate and heat up quickly, making them an excellent choice for low to medium horsepower applications. Worm gear reducer gearboxes can be upgraded to improve their performance by combining with other gear trains or gearboxes.

easy to replace

An easily replaceable worm gear reducer gearbox can save you a lot of money. A worm gear reducer gearbox is part of a chain drive and allows you to change gear ratios quickly and easily. Worm gear reducer gearboxes can be easily replaced in a number of ways. It’s a good idea to read the manufacturer’s manual before replacing a worm gear reducer gearbox. Make sure you have the instructions available so you can refer to them in the future.

Worm gear reducer gearboxes offer many advantages, including long service life and low noise. They are also designed with a 90-degree output shaft for easy installation. Another advantage of these gear reducer gearboxes is that they can be used with both solid and hollow output shafts. This means less maintenance and downtime.

Worm gear reducer gearboxes are widely used. Most gear manufacturers have large inventories. Worm gears also have uniform mounting dimensions. Dimensional consistency means you don’t have to worry about matching the shaft length and diameter to the worm gear. You can easily find a replacement worm gear reducer gearbox for your equipment.

When replacing the worm gear reducer gearbox, check the lubricating oil recommended by the machine. If not included, use original gear oil. Be sure to follow the manufacturer’s instructions carefully.

editor by czh 2023-01-06

China S Series Foot-Mounted Helical Worm Gear Unit with Solid Shaft Electric Motor Speed Reducer Gearbox manufacturer

Product Description

Product Description

Merchandise Description

-S Series Helical gearbox

Solution Features

1.Higher modular layout.

two.Integrated casting housing,compact dimension,high loading assistance, stable transmitting and low sound degree.

three.With the unique gear geometry, it will get higher torque, efficiency and prolonged existence circle.

4.It can achieve the direct blend for 2 sets of gearbox.

5.Substantial performance and conserve electrical power.

6.Save cost and low maintenance.

Solution Parameters

one. Technical data

| Size | 38 | 48 | 58 | 68 | 78 | 88 | ninety eight |

| Composition | BS BSA BSF BSAF BSAT BSAZ | ||||||

| Input Power(kW) | .eighteen~.75 | .eighteen~1.five | .eighteen~three | .25~5.five | .55~7.5 | .seventy five~fifteen | one.5~22 |

| Ratio | 10.27~a hundred sixty five.71 | eleven.forty six~244.74 | ten.78~196.21 | eleven.fifty five~227.twenty | 9.96~241.09 | eleven.83~223.26 | 12.75~230.forty eight |

| Permissible Torque(N.m) | ninety | one hundred seventy | three hundred | 520 | 1270 | 2280 | 4000 |

| Excess weight(kg) | 7 | ten | fourteen | 26 | fifty | 100 | one hundred seventy |

two: Style selection

| S series gear units are available in the following designs | |

| S…Y… | Foot-mounted parallel shaft helical gear units with solid shaft |

| SA…Y… | Parallel shaft helical gear units with hollow shaft |

| SAZ…Y… | Short-flange mounted parallel shaft helical gear units with hollow shaft |

| SF…Y… | Flange-mounted parallel shaft helical gear units with solid shaft |

| SAT…Y… | Flange-mounted parallel shaft helical gear units with hollow shaft |

| S(SF,SA,SAF,SAZ)S… | Shaft input parallel shaft helical gear units |

| S(SF,SA,SAF,SAZ)…R…Y… | Combinatorial parallel shaft helical gear units |

| S(SF,SA,SAF,SAZ)S…R… | Shaft input combinatorial parallel shaft helical gear units |

Resources Information Sheet

|

Housing content |

Grey Forged iron |

|

Housing hardness |

HBS163~255 |

|

Gear material |

20CrMnTi alloy metal |

|

Area hardness of gears |

HRC58°~62 ° |

|

Equipment core hardness |

HRC33~48 |

|

Input / Output shaft material |

40Cr alloy metal |

|

Enter / Output shaft hardness |

HRC32~36 |

|

Machining precision of gears |

correct grinding, 6~5 Quality |

|

Lubricating oil |

GB L-CKC220-460, Shell Omala220-460 |

|

Heat remedy |

tempering, cementiting, quenching, normalizing, and many others. |

|

Efficiency |

ninety four%~96% (depends on the transmission phase) |

|

Sound (MAX) |

sixty~68dB |

|

Temp. increase (MAX) |

40°C |

|

Temp. increase (Oil)(MAX) |

50°C |

|

Vibration |

≤20µm |

|

Backlash |

≤20Arcmin |

|

Model of bearings |

China leading manufacturer bearing, HRB/LYC/ZWZ/C&U. Or other brand names requested, SKF, FAG, INA, NSK. |

|

Manufacturer of oil seal |

NAK — ZheJiang or other brands requested |

Comprehensive Images

Our procedure of generation

Our product line

Business Profile

Business Profile

Bode was founded in 2007, which is located in HangZhou town, ZHangZhoug province. As 1 expert manufacturer and exporter, we have more than seventeen years’ encounter in R & D of worm reducer, gear reducer, gearbox , AC motor and relative spare parts. We have manufacturing facility with advanced manufacturing and check gear, the powerful advancement of team and producing potential offer our customers with large top quality items. Our products broadly served to different industries of Metallurgy, Chemicals, lifting, mining, Petroleum, textile, medicine, picket and many others. Main markets: China, Africa, Australia, Vietnam, Turkey, Japan, Korea, Philippines… Welcome to inquire us any inquiries, excellent provide often for you for extended time period business.

FAQ

Q1: Are you buying and selling organization or company?

A: We are factory.

Q2: What sorts of gearbox can you make for us?

A: Primary merchandise of our firm: R, S, K, F collection helical-tooth reducer, RV collection worm gear reducer,H Sequence Parallel Shaft Helical Reduction Gear Box

Q3: Can you make as for each personalized drawing?

A: Yes, we offer you personalized support for consumers.

Q4: Can we get 1 personal computer of each item for quality testing?

A: Indeed, we are glad to accept trial order for good quality tests.

Q5: What details shall we give prior to putting a acquire get?

A: a) Variety of the gearbox, ratio, enter and output kind, enter flange, mounting placement, and motor informationetc.

b) Housing colour.

c) Acquire quantity.

d) Other specific demands.

Q6: How extended is your delivery time?

A: Typically it is 5-ten days if the products are in inventory. or it is 15-20 times if the products are not in stock.

Q7: What is your terms of payment ?

A: thirty% Progress payment by T/T after signing the agreement.70% ahead of shipping and delivery

If you are fascinated in our item, welcome to make contact with with us.

Our team will do our ideal to meet your need to have 🙂

|

US $90-5,500 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

###

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Size | 38 | 48 | 58 | 68 | 78 | 88 | 98 |

| Structure | BS BSA BSF BSAF BSAT BSAZ | ||||||

| Input Power(kW) | 0.18~0.75 | 0.18~1.5 | 0.18~3 | 0.25~5.5 | 0.55~7.5 | 0.75~15 | 1.5~22 |

| Ratio | 10.27~165.71 | 11.46~244.74 | 10.78~196.21 | 11.55~227.20 | 9.96~241.09 | 11.83~223.26 | 12.75~230.48 |

| Permissible Torque(N.m) | 90 | 170 | 300 | 520 | 1270 | 2280 | 4000 |

| Weight(kg) | 7 | 10 | 14 | 26 | 50 | 100 | 170 |

###

| S series gear units are available in the following designs | |

| S…Y… | Foot-mounted parallel shaft helical gear units with solid shaft |

| SA…Y… | Parallel shaft helical gear units with hollow shaft |

| SAZ…Y… | Short-flange mounted parallel shaft helical gear units with hollow shaft |

| SF…Y… | Flange-mounted parallel shaft helical gear units with solid shaft |

| SAT…Y… | Flange-mounted parallel shaft helical gear units with hollow shaft |

| S(SF,SA,SAF,SAZ)S… | Shaft input parallel shaft helical gear units |

| S(SF,SA,SAF,SAZ)…R…Y… | Combinatorial parallel shaft helical gear units |

| S(SF,SA,SAF,SAZ)S…R… | Shaft input combinatorial parallel shaft helical gear units |

###

|

Housing material

|

Grey Cast iron

|

|

Housing hardness

|

HBS163~255

|

|

Gear material

|

20CrMnTi alloy steel

|

|

Surface hardness of gears

|

HRC58°~62 °

|

|

Gear core hardness

|

HRC33~48

|

|

Input / Output shaft material

|

40Cr alloy steel

|

|

Input / Output shaft hardness

|

HRC32~36

|

|

Machining precision of gears

|

accurate grinding, 6~5 Grade

|

|

Lubricating oil

|

GB L-CKC220-460, Shell Omala220-460

|

|

Heat treatment

|

tempering, cementiting, quenching, normalizing, etc.

|

|

Efficiency

|

94%~96% (depends on the transmission stage)

|

|

Noise (MAX)

|

60~68dB

|

|

Temp. rise (MAX)

|

40°C

|

|

Temp. rise (Oil)(MAX)

|

50°C

|

|

Vibration

|

≤20µm

|

|

Backlash

|

≤20Arcmin

|

|

Brand of bearings

|

China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, FAG, INA, NSK.

|

|

Brand of oil seal

|

NAK — Taiwan or other brands requested

|

|

US $90-5,500 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

###

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Size | 38 | 48 | 58 | 68 | 78 | 88 | 98 |

| Structure | BS BSA BSF BSAF BSAT BSAZ | ||||||

| Input Power(kW) | 0.18~0.75 | 0.18~1.5 | 0.18~3 | 0.25~5.5 | 0.55~7.5 | 0.75~15 | 1.5~22 |

| Ratio | 10.27~165.71 | 11.46~244.74 | 10.78~196.21 | 11.55~227.20 | 9.96~241.09 | 11.83~223.26 | 12.75~230.48 |

| Permissible Torque(N.m) | 90 | 170 | 300 | 520 | 1270 | 2280 | 4000 |

| Weight(kg) | 7 | 10 | 14 | 26 | 50 | 100 | 170 |

###

| S series gear units are available in the following designs | |

| S…Y… | Foot-mounted parallel shaft helical gear units with solid shaft |

| SA…Y… | Parallel shaft helical gear units with hollow shaft |

| SAZ…Y… | Short-flange mounted parallel shaft helical gear units with hollow shaft |

| SF…Y… | Flange-mounted parallel shaft helical gear units with solid shaft |

| SAT…Y… | Flange-mounted parallel shaft helical gear units with hollow shaft |

| S(SF,SA,SAF,SAZ)S… | Shaft input parallel shaft helical gear units |

| S(SF,SA,SAF,SAZ)…R…Y… | Combinatorial parallel shaft helical gear units |

| S(SF,SA,SAF,SAZ)S…R… | Shaft input combinatorial parallel shaft helical gear units |

###

|

Housing material

|

Grey Cast iron

|

|

Housing hardness

|

HBS163~255

|

|

Gear material

|

20CrMnTi alloy steel

|

|

Surface hardness of gears

|

HRC58°~62 °

|

|

Gear core hardness

|

HRC33~48

|

|

Input / Output shaft material

|

40Cr alloy steel

|

|

Input / Output shaft hardness

|

HRC32~36

|

|

Machining precision of gears

|

accurate grinding, 6~5 Grade

|

|

Lubricating oil

|

GB L-CKC220-460, Shell Omala220-460

|

|

Heat treatment

|

tempering, cementiting, quenching, normalizing, etc.

|

|

Efficiency

|

94%~96% (depends on the transmission stage)

|

|

Noise (MAX)

|

60~68dB

|

|

Temp. rise (MAX)

|

40°C

|

|

Temp. rise (Oil)(MAX)

|

50°C

|

|

Vibration

|

≤20µm

|

|

Backlash

|

≤20Arcmin

|

|

Brand of bearings

|

China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, FAG, INA, NSK.

|

|

Brand of oil seal

|

NAK — Taiwan or other brands requested

|

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

editor by czh2022-11-25