Product Description

Professional Forging Parts Manufacturer in China

Molding R&D, Forging, Machining, Surface Treatment, Inspection, Packing & Loading, Aftersale service etc.

| Main Process | Material Cutting, Material Heating, Forging, Heat Treatment, Blasting&Polishing, CNC Machining |

| Material | Aluminum, Carbon Steel, Stainless Steel Brass, ,DC53 or as customer request |

| Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Primer Painting , Powder Coating, ED- Coating, Chromate Plating, Zinc Plating, Dacromat Coating, Finish Painting |

| Application | 1. Construction: lifting anchors for precast concrete, spherical head anchors |

| 2. Automotive industry: piston, connecting rods, cams, camshafts, crankshafts | |

| 3. Heavy machinery: Rock breaker, excavator parts | |

| 4. Energy: Anvil, gate valve, wellhead control EQP, wellhead EQP | |

| 5. Defense: Black receiver, aluminum trigger guards and receivers | |

| 6. Truck: Cylinder heads, oil sump, clutch housing, front and rear brake calipers. | |

| Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/ Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Testing Machine | CMM, Digital Height Gauge, Caliper, Coordinate Measuring Machine, Projecter Machine, Roughness Tester, Hardness Tester and so on |

| Certificate | ISO9001, CE, TUV, SGS or as your requirement to do test by the third party |

| Delivery time | 10-15 days for sample, |

| 35-40 days for bulk order | |

| Packing | Plywood pallet, plywood box or as per your requirement |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Service | Warm and quick response service provided by the professional |

| Export Sales Team with many years’ experience in handling exports to the US, Europe, Japan and other countries and regions. |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Application: | Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Tempering |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

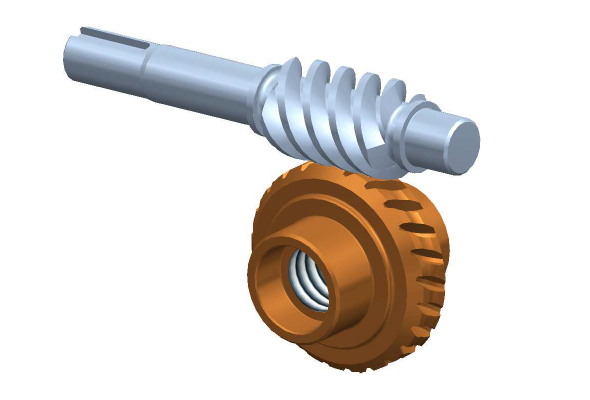

How do you select the right worm screw for a specific application?

Selecting the right worm screw for a specific application involves considering several factors to ensure optimal performance and compatibility. Here are the key steps to guide you in selecting the appropriate worm screw:

- Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as torque, speed, direction of rotation, load capacity, precision, and environmental conditions. Determine the desired gear ratio and any additional features or specifications needed for the worm screw to meet the application’s objectives.

- Consider Design Parameters: Evaluate the design parameters of the worm screw, including the number of starts, lead angle, pitch diameter, and thread profile. These parameters directly influence the gear ratio, mechanical efficiency, and load-carrying capacity of the worm screw. Choose the design parameters that align with the application requirements, considering factors like torque transmission, speed regulation, and size constraints.

- Material Selection: Selecting the right material for the worm screw is crucial for its durability and performance. Consider factors such as strength, wear resistance, and compatibility with other mating components. Common materials for worm screws include hardened steel, stainless steel, bronze, or other alloys. Consult material specifications and consider the anticipated operating conditions to ensure the selected material can withstand the loads and environmental factors present in the application.

- Lubrication Requirements: Determine the lubrication requirements for the specific application. Some worm screws may require lubrication to reduce friction and wear, while others may have self-lubricating properties. Consider the type of lubricant (oil or grease), the frequency of lubrication, and the accessibility for lubrication maintenance. Ensure that the selected worm screw is compatible with the required lubrication method and can meet the lubrication demands of the application.

- Consider Mounting and Installation: Evaluate the mounting and installation requirements of the worm screw. Assess factors such as space limitations, alignment considerations, coupling options, and connection methods. Ensure that the selected worm screw can be easily integrated into the mechanical system and meets the specific installation requirements without compromising overall performance.

- Consult Manufacturer Resources: Utilize manufacturer resources, such as catalogs, technical specifications, and application guidelines, to gather information about available worm screw options. Manufacturers often provide recommendations and selection guides based on different application scenarios and performance criteria. Their expertise can help ensure that you choose the most suitable worm screw for your specific application.

- Review Cost and Availability: Consider the cost and availability of the worm screw. Evaluate the pricing, lead times, and availability from different suppliers or manufacturers. Balance the desired performance and quality with the budget constraints of the project, ensuring that the selected worm screw offers a cost-effective solution without compromising reliability or performance.

By following these steps and considering the application requirements, design parameters, material selection, lubrication needs, mounting considerations, manufacturer resources, and cost factors, you can select the right worm screw that meets the specific demands of your application. It’s important to consult with experts or seek assistance from manufacturers if you require further guidance or have unique requirements.

How does the pitch of a worm screw affect its performance?

The pitch of a worm screw plays a crucial role in determining its performance characteristics and capabilities. The pitch refers to the axial distance between consecutive threads on the worm screw. Here’s how the pitch of a worm screw affects its performance:

- Speed and Efficiency: The pitch of a worm screw directly influences the speed and efficiency of the worm gear system. A smaller pitch, which means a finer thread, results in a higher gear ratio and slower output speed. Conversely, a larger pitch, or coarser thread, leads to a lower gear ratio and faster output speed. This relationship between pitch and speed allows for speed reduction or multiplication in mechanical power transmission systems.

- Load Capacity: The pitch of a worm screw also affects its load-carrying capacity. A finer pitch tends to distribute the load over more threads, resulting in a larger contact area between the worm screw and the worm wheel. This increased contact area improves load distribution and allows for higher load capacity. Coarser pitches, on the other hand, may have a reduced contact area, which can limit the load-carrying capability of the worm gear system.

- Backlash: Backlash is the clearance or play between the threads of the worm screw and the teeth of the worm wheel. The pitch of a worm screw influences the amount of backlash present in the system. A finer pitch generally results in lower backlash due to the smaller clearance between the threads and the teeth. In contrast, coarser pitches may have increased backlash, which can negatively impact the system’s accuracy, precision, and responsiveness.

- Efficiency and Heat Generation: The pitch of a worm screw affects the overall efficiency of the worm gear system. Finer pitches tend to have higher efficiency due to reduced sliding friction between the threads and the teeth. This reduced friction results in less heat generation, contributing to higher overall system efficiency. Coarser pitches, on the other hand, may exhibit increased sliding friction, leading to higher energy losses and heat generation.

- Manufacturing and Design Considerations: The pitch of a worm screw also influences the manufacturing process and design considerations. Finer pitches generally require more precise machining or grinding processes to achieve the desired thread geometry. Coarser pitches, on the other hand, may offer advantages in terms of ease of manufacturing and reduced sensitivity to manufacturing tolerances. The selection of the optimal pitch depends on factors such as the desired gear ratio, load requirements, desired efficiency, and manufacturing capabilities.

It’s important to note that the pitch of a worm screw is typically specified by the manufacturer and should be chosen carefully based on the specific application requirements. Consulting with experts or engineers familiar with worm gear systems can help in selecting the appropriate pitch to achieve the desired performance and functionality.

How does a worm screw mechanism work?

A worm screw mechanism, also known as a worm gear mechanism, is a type of power transmission system that consists of a worm screw and a worm wheel. It is designed to transmit motion and power between non-parallel shafts. The mechanism works based on the interaction between the helical threads of the worm screw and the teeth of the worm wheel. Here’s a detailed explanation of how a worm screw mechanism works:

- Structure: The worm screw is a cylindrical shaft with a helical thread wrapped around it, resembling a screw. The worm wheel, also known as a worm gear, is a gear with teeth that mesh with the threads of the worm screw. The orientation of the worm screw and the worm wheel is such that the axes of rotation are perpendicular to each other.

- Motion Transmission: When the worm screw is rotated, its helical threads engage with the teeth of the worm wheel. As the worm screw rotates, it drives the worm wheel to rotate as well. The helical shape of the worm screw and the teeth of the worm wheel allow for motion transmission perpendicular to the axis of the worm screw.

- Gear Reduction: One of the key characteristics of a worm screw mechanism is its ability to provide a significant gear reduction. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a substantial rotation of the worm wheel. The gear reduction enables the worm screw mechanism to generate high torque output at the worm wheel.

- Self-Locking: A notable feature of the worm screw mechanism is its self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel. This means that the worm wheel cannot easily rotate the worm screw. Instead, the worm screw tends to hold its position without the need for additional braking mechanisms. The self-locking feature makes the worm screw mechanism suitable for applications that require holding loads in a fixed position.

- Efficiency and Backlash: The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. Additionally, worm screw mechanisms may exhibit a certain amount of backlash, which refers to the slight play or clearance between the threads and teeth. Backlash can affect precision and introduce a small amount of lost motion in the system.

- Applications: Worm screw mechanisms find applications in various industries and machinery where motion transmission at right angles and high gear reduction ratios are required. Common applications include conveyor systems, lifting mechanisms, winches, automotive steering systems, robotics, and machine tools.

The worm screw mechanism offers a unique combination of motion transmission, gear reduction, and self-locking capabilities, making it suitable for specific applications where precise control, high torque output, and the ability to hold loads are essential.

editor by CX 2024-01-11

China best High Quality Transmission Parts Drive Shafts Joint Tripod Star 4380673 97FG-3W007-AA For CZPT C-MAX CB3 near me supplier

Model: Fiesta, Target, focus II, Mondeo, C-max, Focus III

12 months: 2007-2571, 2571-2016, 2000-2002, 2008-2008, 2005-2008, 1998-2004, 2003-2005, 2011-2016, 2014-2016, 2004-2008, 2008-2011, 48V 1000W off-highway electric racing pedal go kart with 1 seat 48V Electric powered Go Kart 2007-2014

OE NO.: 1600612 1676318 1692089 175716 1722079

Auto Fitment: Ford

Dimension: 22X30

Materials: Rubber, Rubber Iron, Metal,oil

Product Variety: 1459743 1477836 1481244 1481246 1539167

Guarantee: 2 Years

Car Make: For CZPT FIESTA CB1 CBK

Certification: ISO9001, TS16949

Supply Time: 5-25 times

Sample: Free

OEM: 1726946 1731643 1746601 1758156 1762790

OEM NO: 1805655 1805656 1840170 1S6W-3W007-AA

Port: HangZhou ZheJiang HangZhou GUAGNZHOU

one. Sample is totally free2. Principal export Market place in Europe,North and South The us3. TEMA doing export business currently above seventeen years,nearby in HangZhou,zHangZhoug province.4. 100% OEM, higher good quality products, aggressive manufacturing unit cost 5. Warranty :2 many years or 60000 KM, manufacturing unit is licensed by BUREAU VERITAS6. Our manufacturing facility Focusing on Japanese/Korean car chassis components with more than ten,000 objects7. Superior equipment and skilled revenue personnel with greatest serviceeight. ISO9001:2008 TS 16949 9. We will reply you for your inquiry in 24 several hours

ten. Make sure you inform us what merchandise or what manufacturer vehicle you fascinated in more?We would like to send you our total catalog.

- Product Parameters

Rubber Hardness

35-ninety Shore A

Tensile Strength

7-twenty five Mpa

Ozone Resistant

Maintain Good quality 85%

Growing older Resistant

Preserve good quality 85%

Temperature Resistant

-forty five diploma

Oil Resistant

Quantity Change ten%

Delivery Time

3~7 times for stock product, fifteen~35 times for mass manufacturing

Rubber Materials

NR, EPDM, SBR, Planetary Gearbox Higher torque gear reducer 20kNm a number of-phase compact & tailored style Hefty Obligation durable NBR, CR, and so on.

Metallic Substance

Accordance To DIN, ASTM, JIB, BS, NF, GB Regular

Surface Therapy

Parkerizing, Polishing, Zinc Plated, Spray painted

Heat Remedy

Carburizing, Quench Hardening

Tensile Check

Accordance with Business Standard

Unique Formula

We style the rubber system to match diverse needs,

such as reduced temperature

Model:

FORD C-MAX CAP 2003-2007FORD C-MAX CB3 2007-2571

FORD FIESTA CB1 2008FORD FIESTA CBK 2001-2008 Scorching Sale Well-liked New Designs Parts For 2. 2.2 L Crankshaft Pulley OEM 25182193

FORD Emphasis I CAK 1998-2005FORD Concentrate II 2004-2008

FORD Concentrate II CB4 2008-2011

FORD Focus III CB8 2011-2014FORD FUSION CBK 2001-2008

FORD GRAND C-MAX CB7 2571FORD MONDEO CA2 2007-2014

Other Products

Materials and testing

Our Firm

Packing & Shipping and delivery

Certifications

Exhibition

Our Services

Q1. Are you a Manufacture or Trading Organization?A1:We are producer and we have licence to export automobile parts, we have been in this line for a lot more than seventeen many years.Q2. What types of parts can you offer?A2:1.strut mount 2.engine mount 3.center bearing 4.stabliser link 5.bushing 6.boot 7.manage arm 8.ball joint 9.pulley loafer ten.cv joints 11.bearing 12.resin bushing thirteen.wheel hub 14.cylinder package fifteen.oil seal sixteen.common joint seventeen.throttle valve eighteen.wheel bolt 19.brake pump 20.cylinder piston 21.oil filter 22.head gasket 23.clutch stress plate 24.head gasketQ3. What is your production Direct Time?A3:5 functioning times for goods in inventory ,15-45 times for mass goods.Q4. What is your payment way?A4:We accept payment by western union, T/T, L/C. Typically, 30% deposit in progress, 70% stability before cargo.Q5. Dispatch Port ?A5:HangZhou HangZhou HangZhou ZheJiang Q6. What other provider can you supply?A6:OEM services, welcome to send out us the design drawing to build a new merchandise line. Custom-made support, we can help you to style your packing.Q7. How can I get the warranty?A7:For the duration of the warranty interval, Harmonic Gearbox for robotic arm gearbox any items broken since of the quality dilemma can be transformed for free of charge.We offer 2 several years guarantee commence from the acquire date, but it does not cover damages outcome from any of the pursuing situations:Racing incidentsIncorrect set upDisassembly or modificationsInjury taking place for the duration of transportation

How to Substitute the Generate Shaft

Numerous different features in a vehicle are vital to its working, but the driveshaft is almost certainly the component that needs to be comprehended the most. A ruined or damaged driveshaft can injury numerous other automobile components. This article will clarify how this element works and some of the symptoms that it could require fix. This post is for the typical particular person who desires to correct their auto on their own but could not be common with mechanical repairs or even driveshaft mechanics. You can click the url beneath for more data.

Mend damaged driveshafts

If you personal a car, you ought to know that the driveshaft is an integral element of the vehicle’s driveline. They make sure efficient transmission of energy from the motor to the wheels and drive. Nonetheless, if your driveshaft is damaged or cracked, your motor vehicle will not operate effectively. To preserve your auto risk-free and managing at peak effectiveness, you ought to have it repaired as quickly as achievable. Below are some easy measures to substitute the drive shaft.

1st, diagnose the result in of the generate shaft injury. If your vehicle is generating abnormal noises, the driveshaft might be destroyed. This is simply because worn bushings and bearings help the push shaft. Consequently, the rotation of the generate shaft is influenced. The sound will be squeaks, dings or rattles. After the issue has been identified, it is time to restore the destroyed travel shaft.

Experts can restore your driveshaft at reasonably lower expense. Costs range dependent on the sort of push shaft and its condition. Axle repairs can range from $300 to $1,000. Labor is typically only about $two hundred. A straightforward fix can price amongst $a hundred and fifty and $1700. You will preserve hundreds of bucks if you happen to be in a position to repair the difficulty your self. You may possibly want to invest a couple of a lot more hours educating by yourself about the dilemma before handing it above to a professional for correct prognosis and mend.

The expense of restoring a ruined driveshaft varies by design and company. It can expense as considerably as $2,000 dependent on areas and labor. Although labor expenses can differ, components and labor are typically all around $70. On regular, a destroyed driveshaft repair costs between $four hundred and $600. Nonetheless, these parts can be more costly than that. If you will not want to commit income on unnecessarily expensive repairs, you may need to have to pay out a small more.

Understand how drive shafts perform

Even though a auto motor may possibly be one particular of the most sophisticated parts in your car, the driveshaft has an similarly essential work. The driveshaft transmits the energy of the engine to the wheels, turning the wheels and creating the car go. Driveshaft torque refers to the drive connected with rotational motion. Push shafts should be capable to stand up to intense circumstances or they could split. Driveshafts are not made to bend, so comprehending how they work is essential to the correct operating of the motor vehicle.

The generate shaft includes many factors. The CV connector is one of them. This is the last stop prior to the wheels spin. CV joints are also acknowledged as “doughnut” joints. The CV joint helps harmony the load on the driveshaft, the last stop in between the engine and the ultimate drive assembly. Lastly, the axle is a one rotating shaft that transmits electricity from the final travel assembly to the wheels.

Distinct types of drive shafts have different quantities of joints. They transmit torque from the engine to the wheels and should accommodate distinctions in size and angle. The drive shaft of a entrance-wheel push vehicle normally consists of a connecting shaft, an inner continual velocity joint and an outer fixed joint. They also have anti-lock system rings and torsional dampers to aid them operate efficiently. This manual will aid you understand the basics of driveshafts and maintain your automobile in good form.

The CV joint is the heart of the driveshaft, it allows the wheels of the vehicle to go at a continual velocity. The connector also aids transmit power efficiently. You can discover much more about CV joint driveshafts by looking at the leading 3 driveshaft questions

The U-joint on the intermediate shaft could be worn or destroyed. Small deviations in these joints can trigger slight vibrations and wobble. Over time, these vibrations can use out drivetrain factors, which includes U-joints and differential seals. Added put on on the middle assist bearing is also expected. If your driveshaft is leaking oil, the up coming action is to examine your transmission.

The drive shaft is an crucial element of the vehicle. They transmit electrical power from the motor to the transmission. They also connect the axles and CV joints. When these factors are in very good condition, they transmit power to the wheels. If you uncover them unfastened or trapped, it can result in the motor vehicle to bounce. To make sure proper torque transfer, your auto needs to continue to be on the highway. Although tough streets are normal, bumps and bumps are typical.

Common indicators of ruined driveshafts

If your motor vehicle vibrates seriously beneath, you may possibly be working with a faulty propshaft. This situation limitations your general control of the automobile and are not able to be dismissed. If you listen to this noise regularly, the issue may possibly be the lead to and should be diagnosed as shortly as feasible. Below are some frequent symptoms of a ruined driveshaft. If you knowledge this sounds although driving, you need to have your automobile inspected by a mechanic.

A clanging audio can also be one particular of the symptoms of a ruined driveshaft. A ding could be a signal of a defective U-joint or middle bearing. This can also be a symptom of worn heart bearings. To preserve your car safe and operating effectively, it is very best to have your driveshaft inspected by a qualified mechanic. This can avert critical damage to your vehicle.

A worn travel shaft can cause problems turning, which can be a major basic safety concern. Luckily, there are many techniques to tell if your driveshaft needs services. The initial thing you can do is verify the u-joint by itself. If it moves also considerably or as well minor in any path, it possibly indicates your driveshaft is faulty. Also, rust on the bearing cap seals could show a defective generate shaft.

The up coming time your auto rattles, it might be time for a mechanic to check it out. Whether or not your motor vehicle has a guide or automated transmission, the driveshaft performs an essential position in your vehicle’s performance. When a single or both driveshafts are unsuccessful, it can make the automobile unsafe or extremely hard to generate. Consequently, you ought to have your auto inspected by a mechanic as quickly as possible to avert additional issues.

Your car ought to also be often lubricated with grease and chain to avoid corrosion. This will prevent grease from escaping and causing filth and grease to build up. One more typical indication is a dirty driveshaft. Make certain your telephone is free of charge of debris and in very good condition. Lastly, make sure the driveshaft chain and cover are in place. In most cases, if you notice any of these frequent indicators, your vehicle’s driveshaft must be changed.

Other indications of a ruined driveshaft contain uneven wheel rotation, issues turning the vehicle, and increased drag when trying to switch. A worn U-joint also inhibits the ability of the steering wheel to turn, generating it a lot more tough to change. One more indicator of a faulty driveshaft is the shuddering noise the auto can make when accelerating. Cars with damaged driveshafts ought to be inspected as before long as attainable to keep away from pricey repairs.

China wholesaler Coaxial Input and Output Shafts Zero Backlash Harmonic Drive Motor Reducer with Free Design Custom

Relevant Industries: Production Plant, Machinery Restore Outlets, Industrial Automation Industry

Gearing Arrangement: Harmonic

Output Torque: 65 Nm

Input Velocity: 3000 r/min

Output Velocity: thirty r/min

Software: Robotics

Optimum enter speed allowed: 7000 r/min

Common input speed permitted: 3500 r/min

Transmission mistake: ≤ 60 arc/sec

Again clearance: ≤ 20 arc/sec

Certificate: ISO 9001

Colour: Silver

Customization: Satisfactory

Packing: Carton Box

Material: Stainless Metal

Packaging Information: Carton Box.

FAQExpensive clients, Below is Shiny from HangZhou Han’s Motion Technology Co., companies hardware clean bushing metal straight tube Ltd. We are skilled harmonic push reducer company from China. We can supply precision harmonic travel reducer with outstanding positional and rotational accuracy. Since harmonic drive reducer is customizable, we need to check out your specifications for the reducer first, and then we can aid in choosing the suited types for you. My email deal with is [email protected]. Please really feel totally free to speak to me directly at any time. Thank you. Ideal regards,Shiny ZengGlobal Key Account ManagerHangZhou Han’s Movement Technologies Co., Ltd.

Product Parameters Comprehensive Photographs Our Business

HangZhou Han’s Motion Technological innovation Co., Ltd. is a subsidiary of Han’s Laser Engineering Industry Group Co., Ltd., concentrating on the R& Produced In China Factory Value Diameter 26Mm Cleaning Brush Little one Bottle Areas Clear Plastic Gearbox D, manufacturing and product sales of precision reducers and products, robotic systems and mechatronics tools. Machining centre

High precision grinding machine

High precision lathe

High precision wire slicing equipment

Certifications

Driveshaft structure and vibrations linked with it

The structure of the generate shaft is vital to its efficiency and trustworthiness. Generate shafts generally have claw couplings, rag joints and common joints. Other push shafts have prismatic or splined joints. Learn about the distinct varieties of push shafts and how they operate. If you want to know the vibrations connected with them, study on. But first, let’s outline what a driveshaft is.

transmission shaft

As the demand on our vehicles continues to increase, so does the desire on our push systems. Larger CO2 emission specifications and stricter emission expectations boost the tension on the push technique even though improving convenience and shortening the turning radius. These and other damaging outcomes can area significant anxiety and wear on elements, which can lead to driveshaft failure and increase motor vehicle basic safety dangers. Therefore, the drive shaft need to be inspected and changed regularly.

Dependent on your product, you may possibly only need to replace 1 driveshaft. However, the price to substitute each driveshafts ranges from $650 to $1850. Additionally, you might incur labor charges ranging from $140 to $250. The labor value will count on your car design and its drivetrain type. In common, even so, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market can be divided into 4 main marketplaces: North The us, Europe, Asia Pacific, and Rest of the Planet. North The us is anticipated to dominate the market, whilst Europe and Asia Pacific are predicted to increase the swiftest. Furthermore, the market place is envisioned to grow at the optimum charge in the long term, pushed by financial growth in the Asia Pacific region. Additionally, most of the automobiles bought globally are developed in these regions.

The most critical attribute of the driveshaft is to transfer the power of the engine to helpful perform. Generate shafts are also acknowledged as propeller shafts and cardan shafts. In a automobile, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or equally. Thanks to the complexity of driveshaft assemblies, they are crucial to automobile security. In addition to transmitting torque from the motor, they should also compensate for deflection, angular changes and size changes.

sort

Diverse sorts of drive shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head offer a rotationally secure relationship. At minimum a single bearing has a groove extending alongside its circumferential duration that permits the pin to move through the bearing. There can also be two flanges on every conclude of the shaft. Based on the application, the shaft can be mounted in the most hassle-free location to perform.

Propeller shafts are usually created of higher-quality steel with large distinct power and modulus. Even so, they can also be made from sophisticated composite resources this sort of as carbon fiber, Kevlar and fiberglass. Yet another type of propeller shaft is made of thermoplastic polyamide, which is stiff and has a higher toughness-to-excess weight ratio. Equally drive shafts and screw shafts are employed to drive autos, ships and bikes.

Sliding and tubular yokes are common parts of push shafts. By design, their angles should be equivalent or intersect to supply the appropriate angle of operation. Except if the doing work angles are equal, the shaft vibrates twice for each revolution, triggering torsional vibrations. The ideal way to keep away from this is to make confident the two yokes are correctly aligned. Crucially, these elements have the identical operating angle to guarantee sleek electrical power stream.

The type of push shaft differs according to the kind of motor. Some are geared, whilst other people are non-geared. In some circumstances, the drive shaft is mounted and the motor can rotate and steer. Alternatively, a adaptable shaft can be used to control the velocity and course of the travel. In some apps exactly where linear energy transmission is not feasible, flexible shafts are a beneficial option. For case in point, flexible shafts can be utilized in portable gadgets.

put up

The construction of the generate shaft has a lot of positive aspects in excess of bare metallic. A shaft that is flexible in a number of directions is easier to maintain than a shaft that is rigid in other instructions. The shaft body and coupling flange can be produced of diverse materials, and the flange can be produced of a diverse materials than the primary shaft entire body. For example, the coupling flange can be created of metal. The main shaft human body is preferably flared on at minimum one end, and the at the very least one particular coupling flange includes a first usually frustoconical projection extending into the flared finish of the primary shaft entire body.

The standard stiffness of fiber-dependent shafts is achieved by the orientation of parallel fibers together the size of the shaft. However, the bending stiffness of this shaft is reduced owing to the change in fiber orientation. Considering that the fibers keep on to travel in the exact same direction from the very first conclude to the 2nd finish, the reinforcement that will increase the torsional stiffness of the shaft is not affected. In distinction, a fiber-based mostly shaft is also versatile since it employs ribs that are approximately ninety degrees from the centerline of the shaft.

In addition to the helical ribs, the travel shaft one hundred could also incorporate reinforcing elements. These reinforcing components maintain the structural integrity of the shaft. These reinforcing aspects are referred to as helical ribs. They have ribs on equally the outer and interior surfaces. This is to prevent shaft breakage. These aspects can also be shaped to be flexible adequate to accommodate some of the forces created by the drive. Shafts can be made employing these strategies and manufactured into worm-like generate shafts.

vibration

The most common trigger of generate shaft vibration is inappropriate installation. There are 5 typical sorts of driveshaft vibration, each and every associated to installation parameters. To stop this from going on, you ought to recognize what causes these vibrations and how to correct them. The most common varieties of vibration are outlined under. This post describes some common travel shaft vibration solutions. It may possibly also be useful to think about the guidance of a expert vibration technician for push shaft vibration management.

If you happen to be not sure if the dilemma is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you should make contact with an specialist as quickly as attainable. If vibration persists right after vibration-related repairs, the driveshaft requirements to be changed. If the driveshaft is even now under guarantee, you can repair it oneself.

CV joints are the most frequent result in of 3rd-order driveshaft vibration. If they are binding or fail, they want to be replaced. Alternatively, your CV joints might just be misaligned. If it is loose, you can check out the CV connector. An additional common result in of drive shaft vibration is improper assembly. Poor alignment of the yokes on the two finishes of the shaft can trigger them to vibrate.

Incorrect trim height can also lead to driveshaft vibration. Correct trim peak is required to prevent push shaft wobble. No matter whether your vehicle is new or old, you can complete some fundamental fixes to decrease problems. A single of these solutions requires balancing the travel shaft. 1st, use the hose clamps to connect the weights to it. Subsequent, connect an ounce of excess weight to it and spin it. By carrying out this, you reduce the frequency of vibration.

expense

The worldwide driveshaft market is envisioned to exceed (xxx) million USD by 2028, developing at a compound annual growth charge (CAGR) of XX%. Its soaring development can be attributed to a number of aspects, including increasing urbanization and R&D investments by top market place gamers. The report also involves an in-depth analysis of crucial market place traits and their influence on the business. Furthermore, the report provides a extensive regional evaluation of the Driveshaft Marketplace.

The cost of replacing the travel shaft is dependent on the variety of repair essential and the lead to of the failure. Typical repair fees assortment from $three hundred to $750. Rear-wheel drive vehicles normally value more. But entrance-wheel drive automobiles cost less than 4-wheel generate vehicles. You may also pick to try fixing the driveshaft by yourself. However, it is important to do your investigation and make positive you have the necessary tools and gear to execute the occupation properly.

The report also addresses the competitive landscape of the Travel Shafts market. It involves graphical representations, comprehensive figures, management procedures, and governance factors. Additionally, it includes a in depth expense evaluation. Additionally, the report presents views on the COVID-19 marketplace and foreseeable future trends. The report also gives beneficial info to assist you decide how to contend in your sector. When you acquire a report like this, you are adding reliability to your operate.

A high quality driveshaft can boost your game by guaranteeing length from the tee and strengthening responsiveness. The new material in the shaft design is lighter, much better and more responsive than ever prior to, so it is turning into a crucial component of the driver. And there are a variety of choices to fit any funds. The main aspect to think about when getting a shaft is its high quality. Nevertheless, it is essential to notice that high quality will not occur low cost and you must usually select an axle dependent on what your price range can take care of.