Product Description

Special specifications products can be customized according to the customer request

Hope you build up a long cooperation relationship with us; we will give you a discount and provide the free sample for your reference. Looking CHINAMFG to your inquiry.

| Products | Precision CNC machining parts | |

| Materials | Iron, aluminum, steel, copper, carbon steel, bronze, solder alloy, or as per the customers’ requirements. | |

| Dimensions | According to customer’ s drawing | |

| Surface treatment | Blacking, polishing, anodize, chrome plating, zinc plating, nickel plating, tinting or other as requirement. | |

| Packing | Bubble Bag, plastic bag, carton, plywood box, or as per the customer’ s requirements | |

| Standard | Such as ISO, DIN, GB, CHINAMFG and special standard | |

| Certificate | ISO9001: 2008 | |

| Processing equipment | CNC machine, CNC machining center, CNC cutting machine, radial drill, universal milling machine, high precision surface grinding machine, chamfering machine, etc. | |

| QC System | 100% during production check and random samples before shipment. | |

| Available | OEM, ODM | |

| MOQ | negotiable | |

| Ports | HangZhou or ZheJiang | |

| Delivery | Samples 7-15 days, batch production 30 days. |

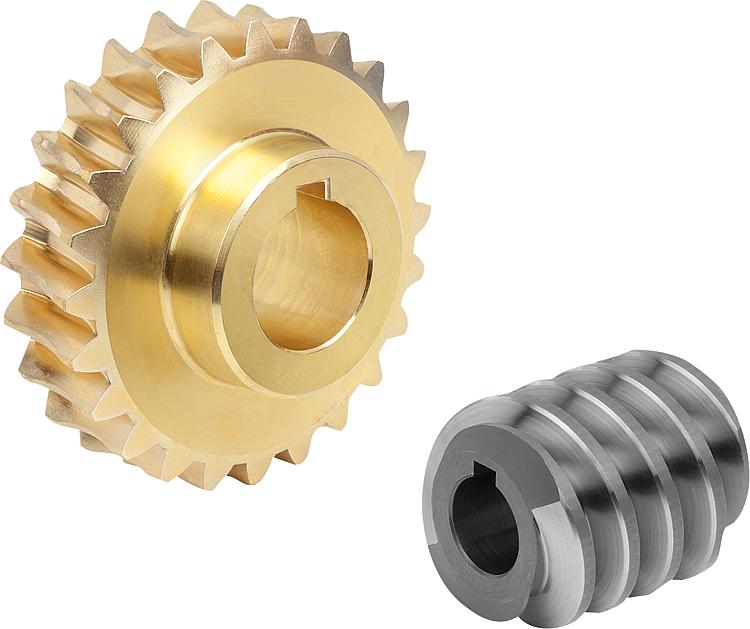

Nblangchi Transmission Technology is a professional manufacturer of lead screw, nuts, valve screw rod, worm and worm gear, which is used for transmission, lift, push-and-pull, fastening. We’re specialized in one-start lead screw, multi-start thread screw, left hand & right hand screw. Thread standard could be GB standard, German standard DIN103, American Standard ACME. The screw material could be carbon steel, alloy steel, stainless steel, copper, aluminum, etc.; nuts material could be brass, tin-bronze, Al-bronze, POM, carbon steel, cast iron, free-cutting steel, etc. Special specifications products can be customized according to the your request, including lead screws, nuts, M0.5-M6 modulus of the worm and the worm gear.

We have a full array of suitable equipment which is more than 200 sets, such as CNC lathe, machine center, milling machine, grinding machine, two-axis rolling and three-axis rolling, punching. Products are now more widely used in many areas. such as smart home, elderly chair, smart lifting table, smart door opener, smart window opener, smart lift, valve, farming machinery, sports equipment and so on. Our products are popular in domestic and foreign market. We mainly export goods to Europe, America and other international markets, which are well received by customers. Welcome come to visit our factory for business discussion, we will do our best to provide you with quality products and service.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the common issues or failures associated with worm screws?

Worm screws, like any mechanical component, can experience certain issues or failures over time. Understanding these common problems is important for proper maintenance and troubleshooting. Here are some common issues or failures associated with worm screws:

- Wear and Surface Damage: Due to the sliding contact between the threads of the worm screw and the teeth of the worm wheel, wear can occur over time. This wear can lead to surface damage, such as pitting, scoring, or galling. Excessive wear and surface damage can affect the performance and efficiency of the worm screw gear system, resulting in increased backlash, decreased torque transmission, and potential failure.

- Lubrication Problems: Inadequate or improper lubrication is a common cause of issues in worm screw systems. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear. On the other hand, over-lubrication can cause excessive drag and fluid churn, leading to inefficient power transmission. It is important to follow the manufacturer’s recommendations for lubrication intervals, types of lubricants, and proper lubrication techniques to ensure optimal performance and longevity of the worm screw system.

- Backlash and Inaccuracy: Backlash refers to the play or clearance between the threads of the worm screw and the teeth of the worm wheel. Excessive backlash can result in reduced accuracy, loss of motion control, and diminished overall system performance. Backlash can be caused by factors such as wear, misalignment, or improper assembly. Regular inspection and adjustment of backlash are necessary to maintain the desired precision and minimize the effects of backlash-related issues.

- Misalignment: Misalignment between the worm screw and the worm wheel can result in increased friction, wear, and inefficiencies. Misalignment can occur due to factors such as improper installation, component deformation, or external forces. It is essential to ensure proper alignment during installation and periodically check for misalignment during routine maintenance. Adjustments should be made as necessary to maintain optimal performance and prevent premature failure.

- Overloading: Subjecting the worm screw gear system to excessive loads beyond its design limits can lead to failure. Overloading can result in accelerated wear, tooth breakage, or component deformation. It is important to operate the system within the specified load limits and consider factors such as shock loads, dynamic loads, and variations in operating conditions. If higher loads are required, it may be necessary to select a worm screw system with a higher load capacity or redesign the system accordingly.

- Corrosion and Contamination: Corrosion and contamination can negatively impact the performance and lifespan of worm screw systems. Exposure to moisture, chemicals, or abrasive particles can lead to corrosion, rusting, or damage to the surfaces of the worm screw and worm wheel. Contamination can interfere with smooth operation and cause accelerated wear. Proper environmental protection, regular cleaning, and appropriate sealing measures can help mitigate the effects of corrosion and contamination.

- Insufficient Stiffness: Worm screws rely on proper support and stiffness to maintain accurate positioning and prevent deflection. Inadequate stiffness in the supporting structure or mounting arrangement can result in excessive deflection, misalignment, and decreased performance. It is crucial to ensure that the worm screw system is properly supported and mounted to maintain the required rigidity and stiffness for optimal operation.

It’s important to note that the specific issues or failures associated with worm screws can vary depending on factors such as the application, operating conditions, maintenance practices, and the quality of the components. Regular inspection, proper lubrication, alignment checks, load monitoring, and adherence to manufacturer guidelines are essential for minimizing the occurrence of these issues and ensuring the reliable and efficient operation of worm screw systems.

Can worm screws be customized for specific engineering needs?

Yes, worm screws can be customized to meet specific engineering needs and application requirements. Customization allows for tailoring the design, dimensions, materials, and other parameters of the worm screw to optimize its performance and functionality. Here are some aspects of worm screws that can be customized:

- Thread Geometry: The thread geometry of a worm screw can be customized to suit specific requirements. This includes the shape, profile, lead angle, and thread form. Custom thread geometries can be designed to optimize load distribution, minimize friction, reduce backlash, improve efficiency, or achieve specific performance characteristics.

- Pitch and Lead: The pitch and lead of a worm screw can be tailored to meet the desired gear ratio, output speed, load capacity, and other performance criteria. Customizing the pitch and lead allows for precise control over the speed reduction or multiplication capabilities of the worm gear system.

- Materials: Worm screws can be customized to be made from different materials based on the specific application requirements. Common materials include steel, stainless steel, bronze, and various alloys. The choice of material depends on factors such as load capacity, durability, corrosion resistance, temperature tolerance, and other environmental considerations.

- Diameter and Length: The diameter and length of a worm screw can be customized to suit the mechanical constraints and dimensional requirements of the application. Custom sizing ensures proper fit, alignment, and integration within the overall system design.

- Coatings and Surface Treatments: Custom coatings or surface treatments can be applied to worm screws to enhance their performance and durability. These can include treatments such as hardening, heat treatment, plating, or specialized coatings to improve wear resistance, reduce friction, or provide corrosion protection.

- Special Features: Worm screws can be customized to incorporate special features or modifications based on specific engineering needs. This may include the addition of keyways, flanges, shaft extensions, or other components to facilitate integration with other system elements or to accommodate unique mechanical requirements.

Customization of worm screws requires collaboration between engineers, designers, and manufacturers with expertise in worm gear systems. It is important to define the specific engineering needs, performance requirements, and operational conditions to ensure that the customized worm screw meets the desired objectives effectively.

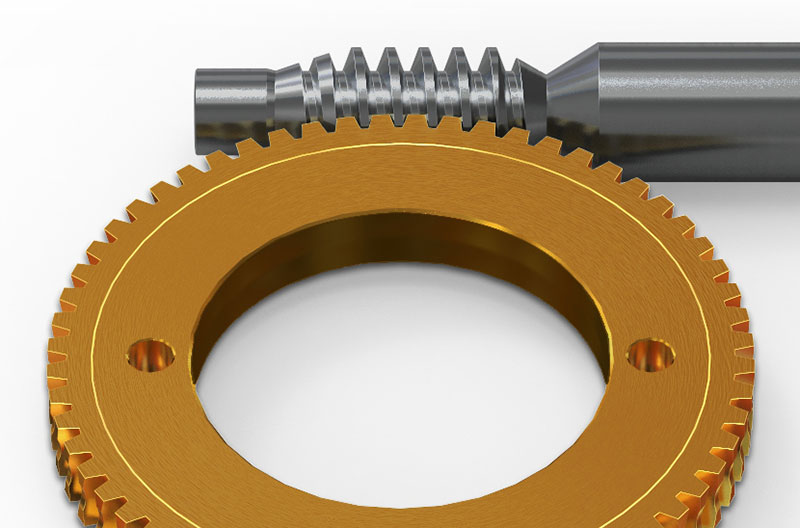

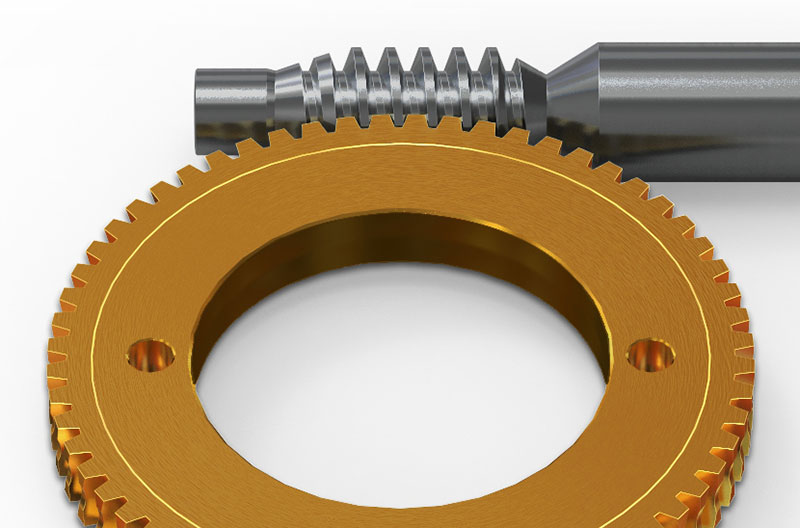

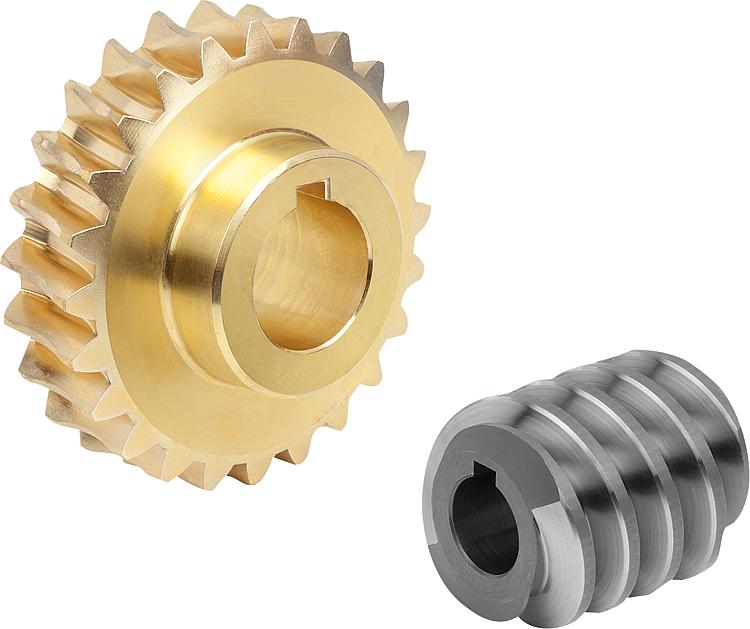

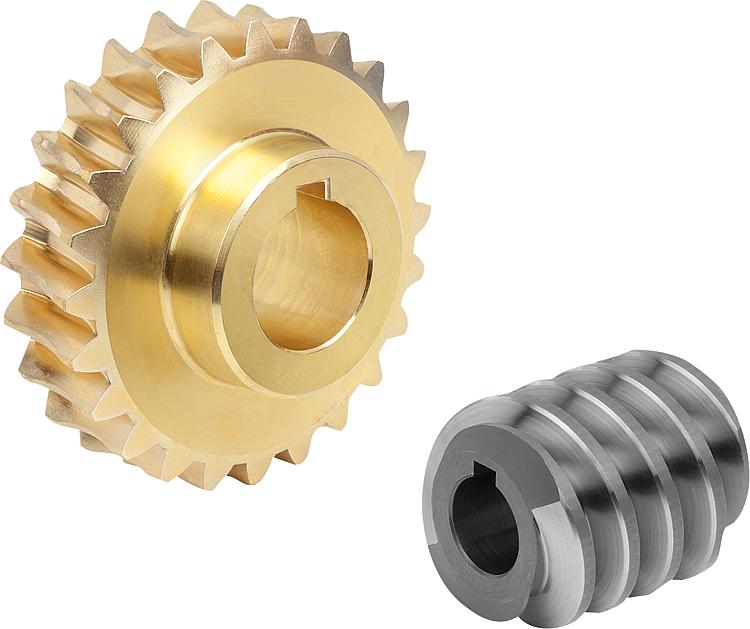

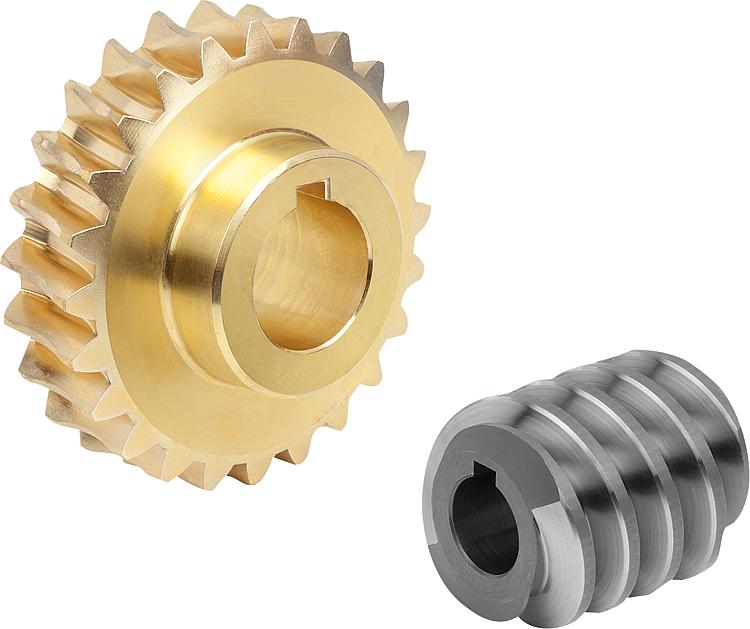

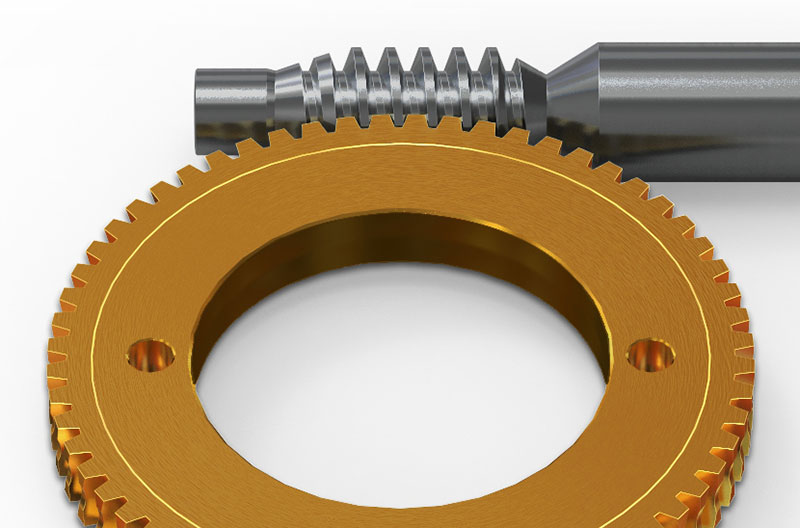

What is a worm screw in mechanical engineering?

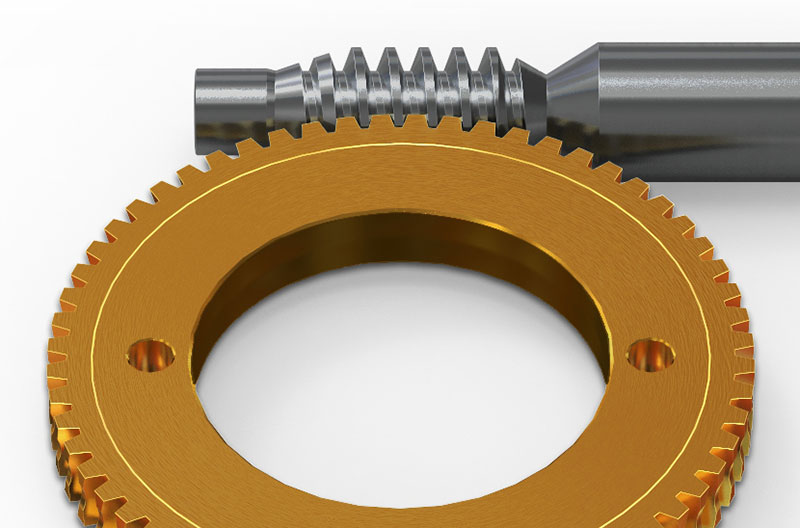

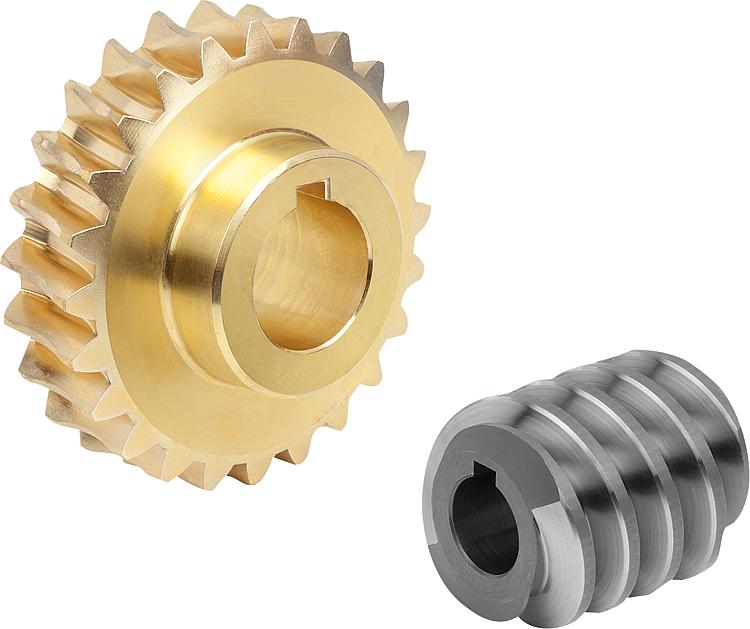

In mechanical engineering, a worm screw, also known as a worm gear screw or worm gear, is a type of gear mechanism used to transmit motion and power between non-parallel shafts. It consists of a spiral-shaped screw, called the worm, and a gear wheel, called the worm wheel or worm gear. The worm screw and worm wheel have helical teeth that mesh together to transfer rotational motion.

The worm screw typically has a single thread or multiple threads wrapped around its cylindrical body. The worm wheel, on the other hand, has teeth that are specially shaped to mesh with the worm screw. The orientation of the worm screw and worm wheel is such that the axes of rotation are perpendicular to each other. This configuration allows the worm screw to convert rotational motion along its axis into rotary motion perpendicular to its axis.

One of the defining characteristics of a worm screw is its high gear ratio. Due to the helical nature of the teeth, a worm screw can achieve a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a substantial rotation of the worm wheel. The ratio of the number of teeth on the worm wheel to the number of threads on the worm screw determines the reduction ratio.

Worm screws have several advantages and applications in mechanical engineering:

- High Reduction Ratio: As mentioned earlier, worm screws offer high gear ratios, making them suitable for applications that require significant speed reduction and torque multiplication. They are commonly used in applications where large gear reductions are needed, such as in conveyor systems, winches, and lifting equipment.

- Self-Locking: A unique characteristic of worm screws is their self-locking property. The angle of the helical teeth creates a wedging effect that prevents the worm wheel from driving the worm screw. This self-locking feature allows worm screws to hold loads without the need for additional braking mechanisms, making them suitable for applications where holding positions or preventing back-driving is crucial, such as in elevators or lifting mechanisms.

- Smooth and Quiet Operation: The helical teeth of the worm screw and worm wheel facilitate smooth and quiet operation. The gradual engagement and disengagement of the teeth minimize noise, vibration, and backlash, resulting in a more efficient and reliable gear mechanism.

- Compact Design: Worm screws offer a compact design compared to other gear mechanisms. The perpendicular arrangement of the worm screw and worm wheel allows for a compact and space-saving installation, making them suitable for applications where size constraints are a consideration.

- Reduction of Input Speed: Worm screws are commonly used to reduce the speed of the input shaft while increasing torque. This is advantageous in applications where slower, controlled motion is required, such as in industrial machinery, conveyors, and robotics.

It should be noted that worm screws also have some limitations, including lower efficiency compared to other gear mechanisms, higher friction due to sliding motion, and limited reverse operation capabilities. Therefore, careful consideration of the specific application requirements is necessary when deciding whether to use a worm screw in a mechanical system.

<img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l1.webp" alt="China Good quality Customized Trapezoidal Thread Rod Trap Shaft Machine Lead Screw Tr20X4 “><img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l2.webp" alt="China Good quality Customized Trapezoidal Thread Rod Trap Shaft Machine Lead Screw Tr20X4 “>

editor by Dream 2024-10-21

China manufacturer CHINAMFG Miniature C7 Ball Screw with 8mm Shaft Diameter for Medical Robot (FXR Series, Lead: 1mm, Shaft: 8mm)

Product Description

FXR Series Square Nut Cold Rolled Ball Screw (C5/Ct7/Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of FXR series square nut cold rolled ball screw are based on C5,Ct7 and Ct10(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5), 0.02(Ct7) and 0.05mm or less(Ct10).

Material & Surface Hardness

FXR series square nut cold rolled ball screw of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shape of the shaft end of the FXR series (square nut cold rolled ball screw) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How do you properly lubricate a worm screw and gear assembly?

Proper lubrication is essential for the smooth and efficient operation of a worm screw and gear assembly. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, thereby extending the lifespan of the components. Here are the steps to properly lubricate a worm screw and gear assembly:

- Clean the Assembly: Before applying lubrication, ensure that the worm screw and gear assembly is free from dirt, debris, and old lubricant residues. Clean the surfaces using an appropriate cleaning agent or solvent, followed by a thorough drying process.

- Select the Right Lubricant: Choose a lubricant specifically designed for gear systems or worm screw applications. Consider factors such as viscosity, temperature range, load capacity, and compatibility with the materials used in the assembly. Consult the manufacturer’s recommendations or lubrication guidelines for the specific assembly to determine the suitable lubricant type and grade.

- Apply the Lubricant: Apply the lubricant to the contacting surfaces of the worm screw and gear assembly. Use an appropriate applicator, such as a brush, oil can, or grease gun, depending on the lubricant form (oil or grease) and the accessibility of the components. Ensure complete coverage of the gear teeth, worm screw threads, and other relevant surfaces. Pay attention to areas where the most significant friction and wear occur.

- Monitor the Lubricant Level: Check the lubricant level regularly to ensure an adequate supply. Depending on the application and operating conditions, lubricant consumption or degradation may occur over time. It is important to maintain the lubricant level within the recommended range to ensure proper lubrication and prevent excessive wear or overheating.

- Periodic Lubrication Maintenance: Establish a lubrication maintenance schedule based on the operating conditions and manufacturer’s recommendations. Regularly inspect the assembly for signs of lubricant degradation, contamination, or insufficient lubrication. Replace the lubricant as needed and follow the recommended intervals for lubricant replenishment or reapplication.

- Consideration for Grease Lubrication: If using grease as the lubricant, it is important to choose a high-quality grease suitable for worm screw applications. Grease provides better adhesion to surfaces and tends to stay in place, offering longer-lasting lubrication compared to oil. However, excessive grease accumulation or over-greasing should be avoided, as it can lead to increased friction and inefficiency.

It is crucial to follow the manufacturer’s guidelines and recommendations for lubrication specific to the worm screw and gear assembly. Different assemblies may have unique lubrication requirements based on their design, load capacity, operating conditions, and materials used. By properly lubricating the worm screw and gear assembly, you can ensure optimal performance, reduce wear, and extend the operational life of the components.

Are there different types of worm screws available?

Yes, there are different types of worm screws available to suit various applications and requirements. The design and characteristics of a worm screw can vary based on factors such as the material used, the thread geometry, the type of worm wheel, and the intended application. Here are some common types of worm screws:

- Standard Worm Screws: Standard worm screws are the most commonly used type and are available in a wide range of sizes and materials. They typically have a single-start thread and are made from materials such as steel, stainless steel, or bronze. Standard worm screws are suitable for general-purpose applications where moderate precision and load capacity are required.

- Double-Enveloping Worm Screws: Double-enveloping worm screws, also known as hourglass worm screws, have a unique thread profile that improves contact and load distribution between the worm screw and the worm wheel. This design offers enhanced torque transmission, higher efficiency, and increased load-carrying capacity compared to standard worm screws. Double-enveloping worm screws are often used in heavy-duty applications, such as gearboxes and high-load power transmission systems.

- Low-Lead Worm Screws: Low-lead worm screws have a smaller thread lead angle compared to standard worm screws. This design reduces the amount of sliding contact between the threads of the worm screw and the teeth of the worm wheel, resulting in lower friction and improved efficiency. Low-lead worm screws are commonly used in applications where high efficiency and reduced heat generation are critical, such as in precision machinery and high-speed gear systems.

- Self-Locking Worm Screws: Self-locking worm screws are designed to have a high friction angle between the threads, making them capable of preventing reverse motion or backdriving. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices in certain applications. Self-locking worm screws are commonly used in vertical lift systems, hoists, and other applications where holding the load position is essential.

- High-Precision Worm Screws: High-precision worm screws are manufactured to tighter tolerances and have improved accuracy compared to standard worm screws. They are designed to provide precise positioning and motion control in applications where high accuracy and repeatability are required. High-precision worm screws are often used in CNC machines, robotics, and other precision equipment.

- Customized Worm Screws: In addition to the standard types mentioned above, worm screws can also be customized to meet specific application requirements. Customized worm screws may involve variations in thread geometry, pitch, diameter, materials, or other parameters to suit unique applications or performance specifications.

The selection of the appropriate type of worm screw depends on factors such as the desired load capacity, efficiency requirements, backlash tolerance, positional accuracy, and environmental conditions. It is important to consult with manufacturers, engineers, or experts familiar with worm screw applications to determine the most suitable type for a specific application.

How does a worm screw differ from a regular screw?

In mechanical engineering, a worm screw differs from a regular screw in several key aspects. While both types of screws have helical threads, their designs and functions are distinct. Here are the primary differences between a worm screw and a regular screw:

- Motion Transmission: The primary function of a regular screw is to convert rotary motion into linear motion or vice versa. It typically has a single-threaded or multi-threaded configuration and is used for applications such as fastening, clamping, or lifting. On the other hand, a worm screw is designed to transmit motion and power between non-parallel shafts. It converts rotary motion along its axis into rotary motion perpendicular to its axis by meshing with a worm wheel or gear.

- Gear Ratio: The gear ratio of a worm screw is typically much higher compared to that of a regular screw. The helical teeth of the worm screw and the worm wheel allow for a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a significant rotation of the worm wheel. In contrast, a regular screw does not have a gear ratio and is primarily used for linear motion or force multiplication.

- Orientation and Shaft Arrangement: A regular screw is typically used in applications where the input and output shafts are parallel or nearly parallel. It transfers motion and force along the same axis. In contrast, a worm screw is designed for applications where the input and output shafts are perpendicular to each other. The orientation of the worm screw and the worm wheel allows for motion transmission between non-parallel shafts.

- Self-Locking: One distinctive characteristic of a worm screw is its self-locking property. The helical teeth of the worm screw create a wedging effect that prevents the worm wheel from driving the worm screw. This self-locking feature allows worm screws to hold loads without the need for additional braking mechanisms. Regular screws, on the other hand, do not have this self-locking capability.

- Applications: Regular screws find widespread use in numerous applications, including construction, manufacturing, woodworking, and everyday objects like screws used in fastening. They are primarily employed for linear motion, clamping, or force multiplication. Worm screws, on the other hand, are commonly used in applications that require significant speed reduction, torque multiplication, or motion transmission at right angles. Typical applications include conveyor systems, winches, lifting mechanisms, and heavy machinery.

These differences in design and function make worm screws and regular screws suitable for distinct applications. Regular screws are more commonly used for linear motion and force transfer along parallel or nearly parallel shafts, while worm screws excel in transmitting motion and power between non-parallel shafts with high gear reduction ratios.

<img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l1.webp" alt="China manufacturer CHINAMFG Miniature C7 Ball Screw with 8mm Shaft Diameter for Medical Robot (FXR Series, Lead: 1mm, Shaft: 8mm) “><img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l2.webp" alt="China manufacturer CHINAMFG Miniature C7 Ball Screw with 8mm Shaft Diameter for Medical Robot (FXR Series, Lead: 1mm, Shaft: 8mm) “>

editor by Dream 2024-10-11

China high quality External Thread Bearing Screw with Shaft Screw Metal Pulley Roller Guide Wheel

Product Description

Detailed Photos

Product Description

Our precision deep groove ball bearings are designed for high precision, low noise, small vibration, high reliability and long life. They are mainly used in various types of electric motors. They are also known as EMQ (Electric Motor Quality) bearings.

EMQ bearings are widely used in household appliances, toys, electric power tools, car motors and other fields. With optimal design, high reliability heat treatment, precision manufacturing processes and high-grade grease, these products perform better on reliability, vibration and noise levels than standard products making them more suitable for electric motor applications. These products can also be applied to most gearbox applications as well.

| Item | Screw Bearing Pulley | Closure type | ZZ/RS |

| OEM ODM | Technical drawing or sample is needed | d(mm) | 10 |

| Original | ZheJiang , China | D(mm) | 40 |

| Material | Chrome steel, Carbon steel, Stainless steel, etc. | B(mm) | 13 |

| Cage Material | Steel / Nylon | Number of row | single |

| Tolerance | P0 P6 P5 P2 P4 | Clearance | C0 C2 C3 C4 |

| Vibration | V1 V2 V3 | Noise | Z1 Z2 Z3 Z4 |

| MOQ | 1000 pcs | Application | Motor/electric/sliding/furniture accessories/ Skateboard/etc. |

| Feature | heavy-duty,adjustable,low noise, easy installation,sliding smoothly,long life,standard,customized,etc | Leading Time | According to the order q’ty |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China, covering an area of 16000 square meters. Our company is bearing manufacturer&bearing distributor.

We have own factory that specialize in the production of bearings. We are in a good position to supply you high quality bearing, the finest price and customized service.

Since it was first established, CHINAMFG was dedicated in research, development and manufacture of bearings.

CHINAMFG deep groove ball bearing has numerous technical advantages, such as increased service life of bearing over a broad of operating temperature and all these combined with the highest level of cost effectiveness.

Now, CHINAMFG has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

1. Our bearing are in stable quality with smooth rotation, long life operation, small movement, advanced heat treatment etc.

2. The Balls with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s adapt in multiple housing choices with any wheels to fit different aluminnum. Our bearing ensure alignment across the full adjustment ranges within built-in retention system.

3. If you need, we also could offer customized hardware service, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

Packaging & Shipping

Packaging Details

Packaging

A.Polybag +Box+Carton

B.B.Tube+Box+Carton

C.As per customer’s request

We have kinds of packages, such as plastic bags, cartons, special boxes. We use different packages based on the products and our customers’ requirements.

Port :HangZhou

Our Advantages

FAQ

If you have any other questions, please feel free to contact us as follows.

Q: Why did you choose us?

A. We provide the best quality bearings with reasonable price, low friction, low noise and long service life.

B. With sufficient stock and fast delivery, you can choose our freight forwarder or your freight forwarder.

C. The best service provided by a well-trained international sales team.

Q: Do you accept small orders?

100% quality check, once your bearings are standard size bearings, even one, we also accept.

Q: Do you provide samples? Is it free or extra?

Yes, we can provide a small amount of free samples. Do you mind paying the freight?

Q: What should I do if I don’t see the type of bearings I need?

We have too many bearing series numbers. Sometimes we can’t put them all on web. Just send us the inquiry and we will be very happy to send you the bearing details.

Q: What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, JPY, CNY;

Accepted Payment Type: T/T, L/C, D/P, D/A

Language Spoken: English, Chinese;

Purchase Notice

1. Please send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2. You can ask us to take actual photos of the products for you, and free samples would be provide.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements.

Finally, please be sure to click “Contact Supplier” to contact us, or “call us” with any questions that you may have.

Welcome to contact me anytime!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Samples: |

US$ 0.67/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can worm screws be used for high torque applications?

Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for applications that require high torque output. Here are some key points to consider regarding the use of worm screws in high torque applications:

- Gear Reduction: One of the primary advantages of a worm screw mechanism is its ability to provide a significant gear reduction in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio, which results in a lower output speed and higher output torque. This gear reduction capability allows worm screws to generate and transmit substantial torque, making them well-suited for high torque applications.

- Efficiency: While worm screws can provide high torque output, it’s important to consider the mechanical efficiency of the system. The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. It’s crucial to ensure that the efficiency of the worm screw mechanism meets the requirements of the specific high torque application.

- Load Holding: Another advantage of worm screws is their self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel, which provides resistance against backward rotation. This self-locking feature allows worm screws to hold loads in a fixed position without the need for additional braking mechanisms. In high torque applications where load holding is required, worm screws can provide reliable and secure positioning.

- Material Selection: The materials used for the worm screw and worm wheel should be carefully selected to withstand high torque loads. Both components should have sufficient strength and wear resistance to handle the transmitted torque without deformation or premature failure. Depending on the specific application requirements, materials such as hardened steel, bronze, or other alloys may be chosen to ensure the durability and performance of the worm screw assembly.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of a worm screw mechanism, especially in high torque applications. Adequate lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, ensuring efficient torque transfer. Regular maintenance, including monitoring lubricant levels and replenishing or replacing the lubricant as needed, is essential to maintain optimal performance and prevent premature wear or failure.

Overall, worm screws can be effectively used in high torque applications, thanks to their gear reduction capabilities, load-holding properties, and efficient torque transmission. However, it’s important to carefully consider factors such as mechanical efficiency, material selection, lubrication, and maintenance to ensure that the worm screw mechanism can meet the specific requirements and demands of the high torque application.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

What are the advantages of using a worm screw in gear systems?

Using a worm screw in gear systems offers several advantages that make it a preferred choice in certain applications. Here are some of the advantages of using a worm screw:

- High Gear Reduction: One of the primary advantages of a worm screw is its ability to provide a high gear reduction ratio in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a significant reduction in rotational speed. This allows for efficient torque multiplication, enabling the transmission of high torque output from the worm screw to the worm wheel. The high gear reduction is beneficial in applications that require slow and powerful movements, such as lifting heavy loads or controlling conveyor systems.

- Compact Design: Worm screw mechanisms are known for their compact design. Compared to other gear systems, such as spur gears or helical gears, a worm screw setup can achieve a similar gear reduction with fewer components. This makes it a space-saving solution, especially in applications where limited space is available or where a compact design is desired.

- Self-Locking: The self-locking property of a worm screw is a significant advantage in many applications. Due to the helical shape of the threads, the worm screw has a natural tendency to hold its position and prevent backward rotation of the worm wheel. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices, simplifying the overall system design and improving safety and stability in applications that require load holding or position locking.

- Right-Angle Transmission: Worm screw mechanisms provide motion transmission at a right angle, allowing for the transfer of motion between non-parallel shafts. This makes them suitable for applications where the input and output shafts are oriented perpendicular to each other. Examples include automotive steering systems, where the rotational motion from the steering wheel needs to be converted into lateral motion for steering the vehicle.

- Quiet Operation: Worm screw gear systems tend to operate quietly compared to other gear configurations. The helical threads of the worm screw and the meshing teeth of the worm wheel engage gradually, resulting in smoother and quieter operation. This can be advantageous in applications where noise reduction is desirable, such as in office equipment, appliances, or environments where low noise levels are required.

It’s important to note that while worm screw mechanisms offer these advantages, there are also some considerations to keep in mind. For instance, worm screws can have lower mechanical efficiency compared to other gear systems due to inherent friction between the threads and teeth, leading to energy losses. Additionally, they may exhibit a certain amount of backlash, which can affect precision and introduce a small amount of lost motion in the system. Nevertheless, the unique characteristics of worm screws make them a valuable choice in various applications where high gear reduction, self-locking, compactness, and right-angle transmission are essential.

editor by Dream 2024-04-26

China Custom Ball Screw Dia 12mm Size Sfu01204 with Shaft Nut Dia 24mm

Product Description

Ball Screw with Nut details

Ball screw is made of screw, nut and ball. The function is to turn the rotary motion into liner motion, which is a further extension and development of ball screw. The significance of this development is to move into a rolling bearing from sliding action; With little friction, ball screws are widely used in various industrial equipment and precision instruments.

WHAT CAN WE SUPPLY?

-1.We have TBI or CHINAMFG sizes for your selection.

Our ball screws and nuts are the same sizes as TBI or CHINAMFG ,they can be interchanged with TBI or THK.

TBI sizes have enough inventory in stock.

THK sizes are produced on request.

-2.We are able to machine the 2 end sides of ball screws according to your requirements.

-3.We have full range of products what can be matched with ball screws.

We are able to match for you completely, including Machined Ball screw, Ball screw Nut, Nut housing/Nut Bracket, Shaft Coupler, End support unit.

-4.We provide many different series of ball screws and screw nuts, like SFU,SFK,SFS,SFI,SFY,SFA,DFU,DFI series and so on.

| SFU Ball Screw Nut Model No.(plastic deflector or metal deflector ) |

| SFU1204-3;SFU1605-3;SFU1605-4; SFU1610-2; SFU2005-3;SFU2005-4;SFU2505-3;SFU2505-4;SFU2510-4;SFU3205-3; SFU3205-4;SFU4005-4;SFU4571-4; SFU5571-4;SFU6310-4;SFU8571-4 |

| SFK Ball Screw Model No. |

| SFK0601;SFK0801;SFK0802;SFK082.5;SFK1002;SFK1004;SFK1202;SFK1402 |

| SFS Ball Screw Model No. |

| SFS1205;SFS1210;SFS1605;SFS1610;SFS1616;SFS1620;SFS2571;SFS2510;SFS2525;SFS3210;SFS4571 |

| SFI Ball Screw Model No. |

| SFI1605;SFI1610;SFI2005;SFI2505;SFI2510;SFI3205;SFI3210;SFI4005;SFI4571 |

| SFE Ball Screw Model No. |

| SFE1616;SFE2571;SFE2525;SFE3232;SFE4040 |

| SFY Ball Screw Model No. |

| SFY1616;SFY2571;SFY2525;SFY3232;SFY4040 |

| SFA Ball Screw Model No. |

| SFA1610;SFA1620;SFA2571;SFA2510;SFA2525 |

| Ball Screw End Supports Model No. |

| BK10 BF10, BK12 BF12, BK15 BF15, BK17 BF17, BK20 BF20, BK25 BF25,BK30 BF30, BK35 BF35, BK40 BF40 |

| EK06 EF06, EK08 EF08, EK10 EF10, EK12 EF12, EK15 EF15, EK20 EF20; EK25 EF25 |

| FK06 FF6, FK08 FF08,FK10 FF10, FK12 FF12, FK15 FF15, FK20 FF20, FK25 FF25, FK30 FF30 |

| Ball Screw Nut Housings Model No. (Aluminium or Iron) |

| DSG12H(1204),DSG16H(1605/1610), DSG20H(2005/2571), DSG25H(2505/2510), DSG32H(3205/3210), DSG40H(4005/4571),DSG50H(5005/5571) |

Each series has its own characteristics. The following table list the differences in appearance and characteristics for your reference.

Rolled Ball Screw Application:

1. Engraving machines; 2. High speed CNC machinery;

4. Auto-machinery. 3. Semi-Conductor equipment;

5. Machine tools; 6. Industrial Machinery;

7. Printing machine; 8. Paper-processing machine;

9. Textiles machine; 10. Electronic machinery;

11. Transport machinery; 12. Robot etc.

Rolled ball screws can not only be used in above general machinery, but also in many advanced industries. Rolled ball screw with a motor assembles electrical-mechanical actuator, which is more eco-friendly than hydraulic pump system. Nowadays it’s applied to electric vehicles, solar power plants, railway devices and many medical and leisure equipments.

Kindly pls contact me if you have any question!!!!!!!!!!!!!!!!!!!!!! /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Screw Diameter: | 11-20mm |

| Flange: | With Flange |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the common issues or failures associated with worm screws?

Worm screws, like any mechanical component, can experience certain issues or failures over time. Understanding these common problems is important for proper maintenance and troubleshooting. Here are some common issues or failures associated with worm screws:

- Wear and Surface Damage: Due to the sliding contact between the threads of the worm screw and the teeth of the worm wheel, wear can occur over time. This wear can lead to surface damage, such as pitting, scoring, or galling. Excessive wear and surface damage can affect the performance and efficiency of the worm screw gear system, resulting in increased backlash, decreased torque transmission, and potential failure.

- Lubrication Problems: Inadequate or improper lubrication is a common cause of issues in worm screw systems. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear. On the other hand, over-lubrication can cause excessive drag and fluid churn, leading to inefficient power transmission. It is important to follow the manufacturer’s recommendations for lubrication intervals, types of lubricants, and proper lubrication techniques to ensure optimal performance and longevity of the worm screw system.

- Backlash and Inaccuracy: Backlash refers to the play or clearance between the threads of the worm screw and the teeth of the worm wheel. Excessive backlash can result in reduced accuracy, loss of motion control, and diminished overall system performance. Backlash can be caused by factors such as wear, misalignment, or improper assembly. Regular inspection and adjustment of backlash are necessary to maintain the desired precision and minimize the effects of backlash-related issues.

- Misalignment: Misalignment between the worm screw and the worm wheel can result in increased friction, wear, and inefficiencies. Misalignment can occur due to factors such as improper installation, component deformation, or external forces. It is essential to ensure proper alignment during installation and periodically check for misalignment during routine maintenance. Adjustments should be made as necessary to maintain optimal performance and prevent premature failure.

- Overloading: Subjecting the worm screw gear system to excessive loads beyond its design limits can lead to failure. Overloading can result in accelerated wear, tooth breakage, or component deformation. It is important to operate the system within the specified load limits and consider factors such as shock loads, dynamic loads, and variations in operating conditions. If higher loads are required, it may be necessary to select a worm screw system with a higher load capacity or redesign the system accordingly.

- Corrosion and Contamination: Corrosion and contamination can negatively impact the performance and lifespan of worm screw systems. Exposure to moisture, chemicals, or abrasive particles can lead to corrosion, rusting, or damage to the surfaces of the worm screw and worm wheel. Contamination can interfere with smooth operation and cause accelerated wear. Proper environmental protection, regular cleaning, and appropriate sealing measures can help mitigate the effects of corrosion and contamination.

- Insufficient Stiffness: Worm screws rely on proper support and stiffness to maintain accurate positioning and prevent deflection. Inadequate stiffness in the supporting structure or mounting arrangement can result in excessive deflection, misalignment, and decreased performance. It is crucial to ensure that the worm screw system is properly supported and mounted to maintain the required rigidity and stiffness for optimal operation.

It’s important to note that the specific issues or failures associated with worm screws can vary depending on factors such as the application, operating conditions, maintenance practices, and the quality of the components. Regular inspection, proper lubrication, alignment checks, load monitoring, and adherence to manufacturer guidelines are essential for minimizing the occurrence of these issues and ensuring the reliable and efficient operation of worm screw systems.

Are there different types of worm screws available?

Yes, there are different types of worm screws available to suit various applications and requirements. The design and characteristics of a worm screw can vary based on factors such as the material used, the thread geometry, the type of worm wheel, and the intended application. Here are some common types of worm screws:

- Standard Worm Screws: Standard worm screws are the most commonly used type and are available in a wide range of sizes and materials. They typically have a single-start thread and are made from materials such as steel, stainless steel, or bronze. Standard worm screws are suitable for general-purpose applications where moderate precision and load capacity are required.

- Double-Enveloping Worm Screws: Double-enveloping worm screws, also known as hourglass worm screws, have a unique thread profile that improves contact and load distribution between the worm screw and the worm wheel. This design offers enhanced torque transmission, higher efficiency, and increased load-carrying capacity compared to standard worm screws. Double-enveloping worm screws are often used in heavy-duty applications, such as gearboxes and high-load power transmission systems.

- Low-Lead Worm Screws: Low-lead worm screws have a smaller thread lead angle compared to standard worm screws. This design reduces the amount of sliding contact between the threads of the worm screw and the teeth of the worm wheel, resulting in lower friction and improved efficiency. Low-lead worm screws are commonly used in applications where high efficiency and reduced heat generation are critical, such as in precision machinery and high-speed gear systems.

- Self-Locking Worm Screws: Self-locking worm screws are designed to have a high friction angle between the threads, making them capable of preventing reverse motion or backdriving. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices in certain applications. Self-locking worm screws are commonly used in vertical lift systems, hoists, and other applications where holding the load position is essential.

- High-Precision Worm Screws: High-precision worm screws are manufactured to tighter tolerances and have improved accuracy compared to standard worm screws. They are designed to provide precise positioning and motion control in applications where high accuracy and repeatability are required. High-precision worm screws are often used in CNC machines, robotics, and other precision equipment.

- Customized Worm Screws: In addition to the standard types mentioned above, worm screws can also be customized to meet specific application requirements. Customized worm screws may involve variations in thread geometry, pitch, diameter, materials, or other parameters to suit unique applications or performance specifications.

The selection of the appropriate type of worm screw depends on factors such as the desired load capacity, efficiency requirements, backlash tolerance, positional accuracy, and environmental conditions. It is important to consult with manufacturers, engineers, or experts familiar with worm screw applications to determine the most suitable type for a specific application.

How does a worm screw mechanism work?

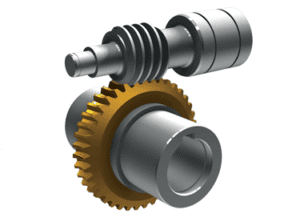

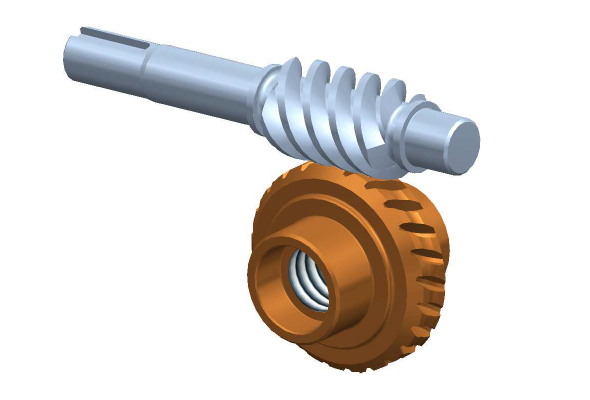

A worm screw mechanism, also known as a worm gear mechanism, is a type of power transmission system that consists of a worm screw and a worm wheel. It is designed to transmit motion and power between non-parallel shafts. The mechanism works based on the interaction between the helical threads of the worm screw and the teeth of the worm wheel. Here’s a detailed explanation of how a worm screw mechanism works:

- Structure: The worm screw is a cylindrical shaft with a helical thread wrapped around it, resembling a screw. The worm wheel, also known as a worm gear, is a gear with teeth that mesh with the threads of the worm screw. The orientation of the worm screw and the worm wheel is such that the axes of rotation are perpendicular to each other.

- Motion Transmission: When the worm screw is rotated, its helical threads engage with the teeth of the worm wheel. As the worm screw rotates, it drives the worm wheel to rotate as well. The helical shape of the worm screw and the teeth of the worm wheel allow for motion transmission perpendicular to the axis of the worm screw.

- Gear Reduction: One of the key characteristics of a worm screw mechanism is its ability to provide a significant gear reduction. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a substantial rotation of the worm wheel. The gear reduction enables the worm screw mechanism to generate high torque output at the worm wheel.

- Self-Locking: A notable feature of the worm screw mechanism is its self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel. This means that the worm wheel cannot easily rotate the worm screw. Instead, the worm screw tends to hold its position without the need for additional braking mechanisms. The self-locking feature makes the worm screw mechanism suitable for applications that require holding loads in a fixed position.

- Efficiency and Backlash: The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. Additionally, worm screw mechanisms may exhibit a certain amount of backlash, which refers to the slight play or clearance between the threads and teeth. Backlash can affect precision and introduce a small amount of lost motion in the system.

- Applications: Worm screw mechanisms find applications in various industries and machinery where motion transmission at right angles and high gear reduction ratios are required. Common applications include conveyor systems, lifting mechanisms, winches, automotive steering systems, robotics, and machine tools.

The worm screw mechanism offers a unique combination of motion transmission, gear reduction, and self-locking capabilities, making it suitable for specific applications where precise control, high torque output, and the ability to hold loads are essential.

editor by CX 2024-04-13

China supplier CHINAMFG Precision 5mm Shaft Rolled Ball Screw with Nuts for Automation (TXR Series, Lead: 1mm, Shaft: 5mm)

Product Description

TXR Series Sleeve Type Single Nut Ball Screw (C5/Ct7/Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of TXR series(sleeve type single nut ball screw)are based on C5,Ct7 and Ct10(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5),0.02(Ct7) and 0.05mm or less(Ct10).

Material & Surface Hardness

TXR series (sleeve type single nut ball screw) of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shape of the shaft end of the TXR series (sleeve type single nut ball screws) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5 |

|---|---|

| Screw Diameter: | 5mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Nut Type: | Sleeve Type Single Nut |

| Customization: |

Available

|

|

|---|

How do you properly lubricate a worm screw and gear assembly?

Proper lubrication is essential for the smooth and efficient operation of a worm screw and gear assembly. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, thereby extending the lifespan of the components. Here are the steps to properly lubricate a worm screw and gear assembly:

- Clean the Assembly: Before applying lubrication, ensure that the worm screw and gear assembly is free from dirt, debris, and old lubricant residues. Clean the surfaces using an appropriate cleaning agent or solvent, followed by a thorough drying process.

- Select the Right Lubricant: Choose a lubricant specifically designed for gear systems or worm screw applications. Consider factors such as viscosity, temperature range, load capacity, and compatibility with the materials used in the assembly. Consult the manufacturer’s recommendations or lubrication guidelines for the specific assembly to determine the suitable lubricant type and grade.

- Apply the Lubricant: Apply the lubricant to the contacting surfaces of the worm screw and gear assembly. Use an appropriate applicator, such as a brush, oil can, or grease gun, depending on the lubricant form (oil or grease) and the accessibility of the components. Ensure complete coverage of the gear teeth, worm screw threads, and other relevant surfaces. Pay attention to areas where the most significant friction and wear occur.

- Monitor the Lubricant Level: Check the lubricant level regularly to ensure an adequate supply. Depending on the application and operating conditions, lubricant consumption or degradation may occur over time. It is important to maintain the lubricant level within the recommended range to ensure proper lubrication and prevent excessive wear or overheating.

- Periodic Lubrication Maintenance: Establish a lubrication maintenance schedule based on the operating conditions and manufacturer’s recommendations. Regularly inspect the assembly for signs of lubricant degradation, contamination, or insufficient lubrication. Replace the lubricant as needed and follow the recommended intervals for lubricant replenishment or reapplication.

- Consideration for Grease Lubrication: If using grease as the lubricant, it is important to choose a high-quality grease suitable for worm screw applications. Grease provides better adhesion to surfaces and tends to stay in place, offering longer-lasting lubrication compared to oil. However, excessive grease accumulation or over-greasing should be avoided, as it can lead to increased friction and inefficiency.

It is crucial to follow the manufacturer’s guidelines and recommendations for lubrication specific to the worm screw and gear assembly. Different assemblies may have unique lubrication requirements based on their design, load capacity, operating conditions, and materials used. By properly lubricating the worm screw and gear assembly, you can ensure optimal performance, reduce wear, and extend the operational life of the components.

What are the latest innovations in worm screw design and materials?

In recent years, there have been several notable innovations in worm screw design and materials that aim to improve performance, efficiency, durability, and overall functionality. Here are some of the latest advancements in this field:

- Advanced Materials: One of the significant trends in worm screw design is the use of advanced materials. Manufacturers are exploring materials with enhanced strength, wear resistance, and fatigue properties. For example, advanced alloys and composite materials are being employed to improve load capacity, reduce weight, and increase the longevity of worm screws. Additionally, advancements in material science and engineering are leading to the development of self-lubricating materials, which can minimize friction and improve efficiency by reducing the need for external lubrication.

- Improved Thread Geometries: Innovations in thread geometries have focused on optimizing load distribution, reducing friction, and improving efficiency. Researchers and engineers are developing novel thread profiles and forms that enhance contact between the worm screw and the worm wheel. These designs help minimize backlash, increase load-carrying capacity, and improve overall system performance. Additionally, advancements in computer simulations and modeling techniques enable more accurate analysis and optimization of thread geometries for specific applications.

- Surface Treatments and Coatings: Surface treatments and coatings are being applied to worm screws to enhance their performance and durability. For instance, advanced coatings such as diamond-like carbon (DLC) coatings or specialized lubricious coatings help reduce friction, improve wear resistance, and minimize the need for external lubrication. Surface treatments like nitriding or carburizing can improve hardness and provide resistance against abrasive wear, increasing the lifespan of worm screws.

- Precision Manufacturing: Innovations in manufacturing processes and technologies have enabled the production of worm screws with higher precision and tighter tolerances. Advanced machining techniques, such as CNC grinding and high-precision gear hobbing, allow for the creation of worm screws with superior dimensional accuracy, improved surface finish, and better tooth profile control. These manufacturing advancements contribute to enhanced performance, reduced backlash, and increased overall system efficiency.

- Computer-Aided Design and Simulation: The use of computer-aided design (CAD) software and simulation tools has revolutionized worm screw design and optimization. Engineers can now create virtual models, simulate the behavior of worm gear systems, and analyze various design parameters to optimize performance before physical prototypes are manufactured. This iterative design process helps reduce development time, minimize costs, and improve the final design and performance of worm screws.

- Integration with Digitalization and Automation: The integration of worm gear systems with digitalization and automation technologies is another area of innovation. Worm screws are being designed to work seamlessly with sensor technologies, allowing for real-time monitoring of performance parameters such as temperature, vibration, and load. This data can be utilized for predictive maintenance, condition monitoring, and optimization of the overall system performance.

It’s important to note that the field of worm screw design and materials is continuously evolving, and new innovations are being introduced regularly. Keeping up with the latest research, advancements, and industry developments is crucial for engineers, designers, and manufacturers involved in worm gear system applications.

What are the advantages of using a worm screw in gear systems?

Using a worm screw in gear systems offers several advantages that make it a preferred choice in certain applications. Here are some of the advantages of using a worm screw:

- High Gear Reduction: One of the primary advantages of a worm screw is its ability to provide a high gear reduction ratio in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a significant reduction in rotational speed. This allows for efficient torque multiplication, enabling the transmission of high torque output from the worm screw to the worm wheel. The high gear reduction is beneficial in applications that require slow and powerful movements, such as lifting heavy loads or controlling conveyor systems.

- Compact Design: Worm screw mechanisms are known for their compact design. Compared to other gear systems, such as spur gears or helical gears, a worm screw setup can achieve a similar gear reduction with fewer components. This makes it a space-saving solution, especially in applications where limited space is available or where a compact design is desired.

- Self-Locking: The self-locking property of a worm screw is a significant advantage in many applications. Due to the helical shape of the threads, the worm screw has a natural tendency to hold its position and prevent backward rotation of the worm wheel. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices, simplifying the overall system design and improving safety and stability in applications that require load holding or position locking.

- Right-Angle Transmission: Worm screw mechanisms provide motion transmission at a right angle, allowing for the transfer of motion between non-parallel shafts. This makes them suitable for applications where the input and output shafts are oriented perpendicular to each other. Examples include automotive steering systems, where the rotational motion from the steering wheel needs to be converted into lateral motion for steering the vehicle.

- Quiet Operation: Worm screw gear systems tend to operate quietly compared to other gear configurations. The helical threads of the worm screw and the meshing teeth of the worm wheel engage gradually, resulting in smoother and quieter operation. This can be advantageous in applications where noise reduction is desirable, such as in office equipment, appliances, or environments where low noise levels are required.

It’s important to note that while worm screw mechanisms offer these advantages, there are also some considerations to keep in mind. For instance, worm screws can have lower mechanical efficiency compared to other gear systems due to inherent friction between the threads and teeth, leading to energy losses. Additionally, they may exhibit a certain amount of backlash, which can affect precision and introduce a small amount of lost motion in the system. Nevertheless, the unique characteristics of worm screws make them a valuable choice in various applications where high gear reduction, self-locking, compactness, and right-angle transmission are essential.

editor by CX 2024-04-10

China high quality CHINAMFG Cold Rolled 10mm Shaft Diameter Thread Ball Screw for Mining Equipment (BSD Series, Lead: 10mm, Shaft: 10mm)

Product Description

BSD Series Stepped Cold Rolled Ball Screw (C5/Ct7)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of BSD series(standard stepped cold rolled ball screw) are based on C5 and Ct7(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5) and 0.02mm or less(Ct7).

Material & Surface Hardness

BSD series (Standard Stepped cold rolled ball screw) of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shape of the shaft end of the BSD series (stepped cold rolled ball screw) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5/C7 |

|---|---|

| Screw Diameter: | 10mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 3-Row |

| Nut Type: | Stepped Type |

| Customization: |

Available

|

|

|---|

How do you properly lubricate a worm screw and gear assembly?

Proper lubrication is essential for the smooth and efficient operation of a worm screw and gear assembly. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, thereby extending the lifespan of the components. Here are the steps to properly lubricate a worm screw and gear assembly:

- Clean the Assembly: Before applying lubrication, ensure that the worm screw and gear assembly is free from dirt, debris, and old lubricant residues. Clean the surfaces using an appropriate cleaning agent or solvent, followed by a thorough drying process.

- Select the Right Lubricant: Choose a lubricant specifically designed for gear systems or worm screw applications. Consider factors such as viscosity, temperature range, load capacity, and compatibility with the materials used in the assembly. Consult the manufacturer’s recommendations or lubrication guidelines for the specific assembly to determine the suitable lubricant type and grade.

- Apply the Lubricant: Apply the lubricant to the contacting surfaces of the worm screw and gear assembly. Use an appropriate applicator, such as a brush, oil can, or grease gun, depending on the lubricant form (oil or grease) and the accessibility of the components. Ensure complete coverage of the gear teeth, worm screw threads, and other relevant surfaces. Pay attention to areas where the most significant friction and wear occur.

- Monitor the Lubricant Level: Check the lubricant level regularly to ensure an adequate supply. Depending on the application and operating conditions, lubricant consumption or degradation may occur over time. It is important to maintain the lubricant level within the recommended range to ensure proper lubrication and prevent excessive wear or overheating.

- Periodic Lubrication Maintenance: Establish a lubrication maintenance schedule based on the operating conditions and manufacturer’s recommendations. Regularly inspect the assembly for signs of lubricant degradation, contamination, or insufficient lubrication. Replace the lubricant as needed and follow the recommended intervals for lubricant replenishment or reapplication.