Product Description

|

Material |

Low carbon steel( 1214, 1215, Y20, Y35), medium carbon steel( S45C, 4140, 4340) / Stainless steeL, 303, 304, 316 / Aluminum 6061, 6063, 7075 / Brass / Bronze / Copper / Titanium / Plastic (POM, PEEK, Nylon, Acrylic, PMMA, PVC, Derlin, ABS, HDEP) And Customized raw material,ect. |

|

Color |

According to customer’s requests |

|

Standard |

ROHS, HE, ISO9000-2008, IGS, TS16949 etc. |

|

Surface treatment |

Heat treatment, polishing electropolishing, plating, electrophresis, black oxide, galvanizing, cold galvanizing, powder coating, paint coating, sand blasting, shot blasting, anodize,passivasion etching,PAD printing, laster carving,dacromet, nickel plating,ect. |

|

Process |

Purchasing raw material / do Inspection on raw material (IQC) / make samples / Inspection samples(QC and engineer) / Sample approvel by customer / Mass production(LQC,PQC) / Surface finish (IQC) / Packing (FQC) / Make Delivery(FQC). |

|

Capabilities |

cnc turning/milling/machining stamping/bending/welding tapping/knurling/Thread hobbing/heading/chamfering Solidworks, STEP, IGS, AutoCAD |

|

Used |

electronics, electrical appliances, furniture, construction, toys, automotive /motorcycle, machinery, kitchen home appliances and other fields |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Stainless Steel |

|---|---|

| Surface Finishing: | Zinc Plated |

| Grade: | Custom Service |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you select the right worm screw for a specific application?

Selecting the right worm screw for a specific application involves considering several factors to ensure optimal performance and compatibility. Here are the key steps to guide you in selecting the appropriate worm screw:

- Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as torque, speed, direction of rotation, load capacity, precision, and environmental conditions. Determine the desired gear ratio and any additional features or specifications needed for the worm screw to meet the application’s objectives.

- Consider Design Parameters: Evaluate the design parameters of the worm screw, including the number of starts, lead angle, pitch diameter, and thread profile. These parameters directly influence the gear ratio, mechanical efficiency, and load-carrying capacity of the worm screw. Choose the design parameters that align with the application requirements, considering factors like torque transmission, speed regulation, and size constraints.

- Material Selection: Selecting the right material for the worm screw is crucial for its durability and performance. Consider factors such as strength, wear resistance, and compatibility with other mating components. Common materials for worm screws include hardened steel, stainless steel, bronze, or other alloys. Consult material specifications and consider the anticipated operating conditions to ensure the selected material can withstand the loads and environmental factors present in the application.

- Lubrication Requirements: Determine the lubrication requirements for the specific application. Some worm screws may require lubrication to reduce friction and wear, while others may have self-lubricating properties. Consider the type of lubricant (oil or grease), the frequency of lubrication, and the accessibility for lubrication maintenance. Ensure that the selected worm screw is compatible with the required lubrication method and can meet the lubrication demands of the application.

- Consider Mounting and Installation: Evaluate the mounting and installation requirements of the worm screw. Assess factors such as space limitations, alignment considerations, coupling options, and connection methods. Ensure that the selected worm screw can be easily integrated into the mechanical system and meets the specific installation requirements without compromising overall performance.

- Consult Manufacturer Resources: Utilize manufacturer resources, such as catalogs, technical specifications, and application guidelines, to gather information about available worm screw options. Manufacturers often provide recommendations and selection guides based on different application scenarios and performance criteria. Their expertise can help ensure that you choose the most suitable worm screw for your specific application.

- Review Cost and Availability: Consider the cost and availability of the worm screw. Evaluate the pricing, lead times, and availability from different suppliers or manufacturers. Balance the desired performance and quality with the budget constraints of the project, ensuring that the selected worm screw offers a cost-effective solution without compromising reliability or performance.

By following these steps and considering the application requirements, design parameters, material selection, lubrication needs, mounting considerations, manufacturer resources, and cost factors, you can select the right worm screw that meets the specific demands of your application. It’s important to consult with experts or seek assistance from manufacturers if you require further guidance or have unique requirements.

What are the latest innovations in worm screw design and materials?

In recent years, there have been several notable innovations in worm screw design and materials that aim to improve performance, efficiency, durability, and overall functionality. Here are some of the latest advancements in this field:

- Advanced Materials: One of the significant trends in worm screw design is the use of advanced materials. Manufacturers are exploring materials with enhanced strength, wear resistance, and fatigue properties. For example, advanced alloys and composite materials are being employed to improve load capacity, reduce weight, and increase the longevity of worm screws. Additionally, advancements in material science and engineering are leading to the development of self-lubricating materials, which can minimize friction and improve efficiency by reducing the need for external lubrication.

- Improved Thread Geometries: Innovations in thread geometries have focused on optimizing load distribution, reducing friction, and improving efficiency. Researchers and engineers are developing novel thread profiles and forms that enhance contact between the worm screw and the worm wheel. These designs help minimize backlash, increase load-carrying capacity, and improve overall system performance. Additionally, advancements in computer simulations and modeling techniques enable more accurate analysis and optimization of thread geometries for specific applications.

- Surface Treatments and Coatings: Surface treatments and coatings are being applied to worm screws to enhance their performance and durability. For instance, advanced coatings such as diamond-like carbon (DLC) coatings or specialized lubricious coatings help reduce friction, improve wear resistance, and minimize the need for external lubrication. Surface treatments like nitriding or carburizing can improve hardness and provide resistance against abrasive wear, increasing the lifespan of worm screws.

- Precision Manufacturing: Innovations in manufacturing processes and technologies have enabled the production of worm screws with higher precision and tighter tolerances. Advanced machining techniques, such as CNC grinding and high-precision gear hobbing, allow for the creation of worm screws with superior dimensional accuracy, improved surface finish, and better tooth profile control. These manufacturing advancements contribute to enhanced performance, reduced backlash, and increased overall system efficiency.

- Computer-Aided Design and Simulation: The use of computer-aided design (CAD) software and simulation tools has revolutionized worm screw design and optimization. Engineers can now create virtual models, simulate the behavior of worm gear systems, and analyze various design parameters to optimize performance before physical prototypes are manufactured. This iterative design process helps reduce development time, minimize costs, and improve the final design and performance of worm screws.

- Integration with Digitalization and Automation: The integration of worm gear systems with digitalization and automation technologies is another area of innovation. Worm screws are being designed to work seamlessly with sensor technologies, allowing for real-time monitoring of performance parameters such as temperature, vibration, and load. This data can be utilized for predictive maintenance, condition monitoring, and optimization of the overall system performance.

It’s important to note that the field of worm screw design and materials is continuously evolving, and new innovations are being introduced regularly. Keeping up with the latest research, advancements, and industry developments is crucial for engineers, designers, and manufacturers involved in worm gear system applications.

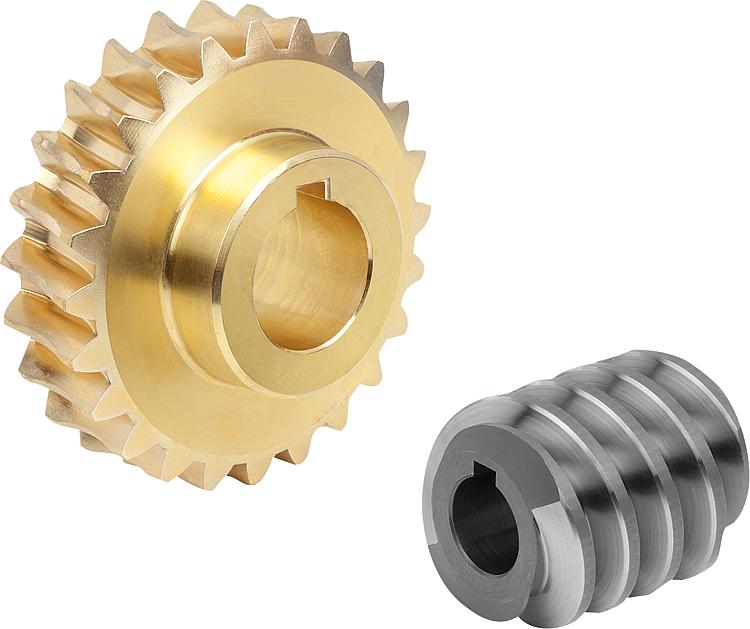

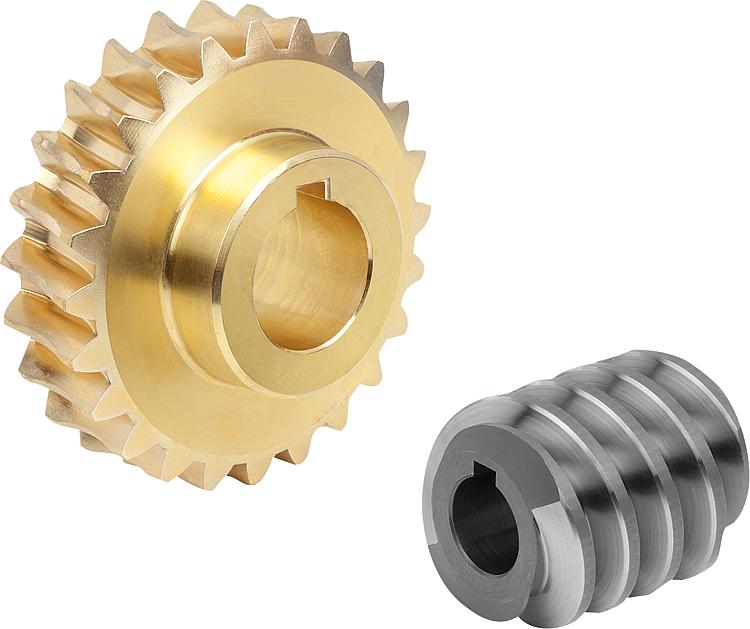

What is a worm screw in mechanical engineering?

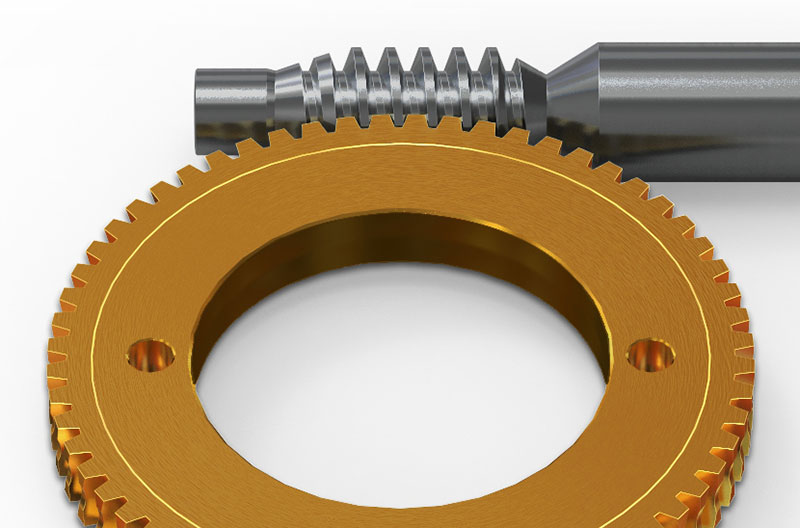

In mechanical engineering, a worm screw, also known as a worm gear screw or worm gear, is a type of gear mechanism used to transmit motion and power between non-parallel shafts. It consists of a spiral-shaped screw, called the worm, and a gear wheel, called the worm wheel or worm gear. The worm screw and worm wheel have helical teeth that mesh together to transfer rotational motion.

The worm screw typically has a single thread or multiple threads wrapped around its cylindrical body. The worm wheel, on the other hand, has teeth that are specially shaped to mesh with the worm screw. The orientation of the worm screw and worm wheel is such that the axes of rotation are perpendicular to each other. This configuration allows the worm screw to convert rotational motion along its axis into rotary motion perpendicular to its axis.

One of the defining characteristics of a worm screw is its high gear ratio. Due to the helical nature of the teeth, a worm screw can achieve a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a substantial rotation of the worm wheel. The ratio of the number of teeth on the worm wheel to the number of threads on the worm screw determines the reduction ratio.

Worm screws have several advantages and applications in mechanical engineering:

- High Reduction Ratio: As mentioned earlier, worm screws offer high gear ratios, making them suitable for applications that require significant speed reduction and torque multiplication. They are commonly used in applications where large gear reductions are needed, such as in conveyor systems, winches, and lifting equipment.

- Self-Locking: A unique characteristic of worm screws is their self-locking property. The angle of the helical teeth creates a wedging effect that prevents the worm wheel from driving the worm screw. This self-locking feature allows worm screws to hold loads without the need for additional braking mechanisms, making them suitable for applications where holding positions or preventing back-driving is crucial, such as in elevators or lifting mechanisms.

- Smooth and Quiet Operation: The helical teeth of the worm screw and worm wheel facilitate smooth and quiet operation. The gradual engagement and disengagement of the teeth minimize noise, vibration, and backlash, resulting in a more efficient and reliable gear mechanism.

- Compact Design: Worm screws offer a compact design compared to other gear mechanisms. The perpendicular arrangement of the worm screw and worm wheel allows for a compact and space-saving installation, making them suitable for applications where size constraints are a consideration.

- Reduction of Input Speed: Worm screws are commonly used to reduce the speed of the input shaft while increasing torque. This is advantageous in applications where slower, controlled motion is required, such as in industrial machinery, conveyors, and robotics.

It should be noted that worm screws also have some limitations, including lower efficiency compared to other gear mechanisms, higher friction due to sliding motion, and limited reverse operation capabilities. Therefore, careful consideration of the specific application requirements is necessary when deciding whether to use a worm screw in a mechanical system.

editor by CX 2024-01-09

China factory Hot Selling Manufacturers Custom Galvanized Worm Gear Brass Gear Worm Gear Shaft Screw

Product Description

|

Material |

Low carbon steel( 1214, 1215, Y20, Y35), medium carbon steel( S45C, 4140, 4340) / Stainless steeL, 303, 304, 316 / Aluminum 6061, 6063, 7075 / Brass / Bronze / Copper / Titanium / Plastic (POM, PEEK, Nylon, Acrylic, PMMA, PVC, Derlin, ABS, HDEP) And Customized raw material,ect. |

|

Color |

According to customer’s requests |

|

Standard |

ROHS, HE, ISO9000-2008, IGS, TS16949 etc. |

|

Surface treatment |

Heat treatment, polishing electropolishing, plating, electrophresis, black oxide, galvanizing, cold galvanizing, powder coating, paint coating, sand blasting, shot blasting, anodize,passivasion etching,PAD printing, laster carving,dacromet, nickel plating,ect. |

|

Process |

Purchasing raw material / do Inspection on raw material (IQC) / make samples / Inspection samples(QC and engineer) / Sample approvel by customer / Mass production(LQC,PQC) / Surface finish (IQC) / Packing (FQC) / Make Delivery(FQC). |

|

Capabilities |

cnc turning/milling/machining stamping/bending/welding tapping/knurling/Thread hobbing/heading/chamfering Solidworks, STEP, IGS, AutoCAD |

|

Used |

electronics, electrical appliances, furniture, construction, toys, automotive /motorcycle, machinery, kitchen home appliances and other fields |

| Material: | Stainless Steel |

|---|---|

| Surface Finishing: | Zinc Plated |

| Grade: | Custom Service |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you select the right worm screw for a specific application?

Selecting the right worm screw for a specific application involves considering several factors to ensure optimal performance and compatibility. Here are the key steps to guide you in selecting the appropriate worm screw:

- Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as torque, speed, direction of rotation, load capacity, precision, and environmental conditions. Determine the desired gear ratio and any additional features or specifications needed for the worm screw to meet the application’s objectives.

- Consider Design Parameters: Evaluate the design parameters of the worm screw, including the number of starts, lead angle, pitch diameter, and thread profile. These parameters directly influence the gear ratio, mechanical efficiency, and load-carrying capacity of the worm screw. Choose the design parameters that align with the application requirements, considering factors like torque transmission, speed regulation, and size constraints.

- Material Selection: Selecting the right material for the worm screw is crucial for its durability and performance. Consider factors such as strength, wear resistance, and compatibility with other mating components. Common materials for worm screws include hardened steel, stainless steel, bronze, or other alloys. Consult material specifications and consider the anticipated operating conditions to ensure the selected material can withstand the loads and environmental factors present in the application.

- Lubrication Requirements: Determine the lubrication requirements for the specific application. Some worm screws may require lubrication to reduce friction and wear, while others may have self-lubricating properties. Consider the type of lubricant (oil or grease), the frequency of lubrication, and the accessibility for lubrication maintenance. Ensure that the selected worm screw is compatible with the required lubrication method and can meet the lubrication demands of the application.

- Consider Mounting and Installation: Evaluate the mounting and installation requirements of the worm screw. Assess factors such as space limitations, alignment considerations, coupling options, and connection methods. Ensure that the selected worm screw can be easily integrated into the mechanical system and meets the specific installation requirements without compromising overall performance.

- Consult Manufacturer Resources: Utilize manufacturer resources, such as catalogs, technical specifications, and application guidelines, to gather information about available worm screw options. Manufacturers often provide recommendations and selection guides based on different application scenarios and performance criteria. Their expertise can help ensure that you choose the most suitable worm screw for your specific application.

- Review Cost and Availability: Consider the cost and availability of the worm screw. Evaluate the pricing, lead times, and availability from different suppliers or manufacturers. Balance the desired performance and quality with the budget constraints of the project, ensuring that the selected worm screw offers a cost-effective solution without compromising reliability or performance.

By following these steps and considering the application requirements, design parameters, material selection, lubrication needs, mounting considerations, manufacturer resources, and cost factors, you can select the right worm screw that meets the specific demands of your application. It’s important to consult with experts or seek assistance from manufacturers if you require further guidance or have unique requirements.

Are there different types of worm screws available?

Yes, there are different types of worm screws available to suit various applications and requirements. The design and characteristics of a worm screw can vary based on factors such as the material used, the thread geometry, the type of worm wheel, and the intended application. Here are some common types of worm screws:

- Standard Worm Screws: Standard worm screws are the most commonly used type and are available in a wide range of sizes and materials. They typically have a single-start thread and are made from materials such as steel, stainless steel, or bronze. Standard worm screws are suitable for general-purpose applications where moderate precision and load capacity are required.

- Double-Enveloping Worm Screws: Double-enveloping worm screws, also known as hourglass worm screws, have a unique thread profile that improves contact and load distribution between the worm screw and the worm wheel. This design offers enhanced torque transmission, higher efficiency, and increased load-carrying capacity compared to standard worm screws. Double-enveloping worm screws are often used in heavy-duty applications, such as gearboxes and high-load power transmission systems.

- Low-Lead Worm Screws: Low-lead worm screws have a smaller thread lead angle compared to standard worm screws. This design reduces the amount of sliding contact between the threads of the worm screw and the teeth of the worm wheel, resulting in lower friction and improved efficiency. Low-lead worm screws are commonly used in applications where high efficiency and reduced heat generation are critical, such as in precision machinery and high-speed gear systems.

- Self-Locking Worm Screws: Self-locking worm screws are designed to have a high friction angle between the threads, making them capable of preventing reverse motion or backdriving. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices in certain applications. Self-locking worm screws are commonly used in vertical lift systems, hoists, and other applications where holding the load position is essential.

- High-Precision Worm Screws: High-precision worm screws are manufactured to tighter tolerances and have improved accuracy compared to standard worm screws. They are designed to provide precise positioning and motion control in applications where high accuracy and repeatability are required. High-precision worm screws are often used in CNC machines, robotics, and other precision equipment.

- Customized Worm Screws: In addition to the standard types mentioned above, worm screws can also be customized to meet specific application requirements. Customized worm screws may involve variations in thread geometry, pitch, diameter, materials, or other parameters to suit unique applications or performance specifications.

The selection of the appropriate type of worm screw depends on factors such as the desired load capacity, efficiency requirements, backlash tolerance, positional accuracy, and environmental conditions. It is important to consult with manufacturers, engineers, or experts familiar with worm screw applications to determine the most suitable type for a specific application.

What are the advantages of using a worm screw in gear systems?

Using a worm screw in gear systems offers several advantages that make it a preferred choice in certain applications. Here are some of the advantages of using a worm screw:

- High Gear Reduction: One of the primary advantages of a worm screw is its ability to provide a high gear reduction ratio in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a significant reduction in rotational speed. This allows for efficient torque multiplication, enabling the transmission of high torque output from the worm screw to the worm wheel. The high gear reduction is beneficial in applications that require slow and powerful movements, such as lifting heavy loads or controlling conveyor systems.

- Compact Design: Worm screw mechanisms are known for their compact design. Compared to other gear systems, such as spur gears or helical gears, a worm screw setup can achieve a similar gear reduction with fewer components. This makes it a space-saving solution, especially in applications where limited space is available or where a compact design is desired.

- Self-Locking: The self-locking property of a worm screw is a significant advantage in many applications. Due to the helical shape of the threads, the worm screw has a natural tendency to hold its position and prevent backward rotation of the worm wheel. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices, simplifying the overall system design and improving safety and stability in applications that require load holding or position locking.

- Right-Angle Transmission: Worm screw mechanisms provide motion transmission at a right angle, allowing for the transfer of motion between non-parallel shafts. This makes them suitable for applications where the input and output shafts are oriented perpendicular to each other. Examples include automotive steering systems, where the rotational motion from the steering wheel needs to be converted into lateral motion for steering the vehicle.

- Quiet Operation: Worm screw gear systems tend to operate quietly compared to other gear configurations. The helical threads of the worm screw and the meshing teeth of the worm wheel engage gradually, resulting in smoother and quieter operation. This can be advantageous in applications where noise reduction is desirable, such as in office equipment, appliances, or environments where low noise levels are required.

It’s important to note that while worm screw mechanisms offer these advantages, there are also some considerations to keep in mind. For instance, worm screws can have lower mechanical efficiency compared to other gear systems due to inherent friction between the threads and teeth, leading to energy losses. Additionally, they may exhibit a certain amount of backlash, which can affect precision and introduce a small amount of lost motion in the system. Nevertheless, the unique characteristics of worm screws make them a valuable choice in various applications where high gear reduction, self-locking, compactness, and right-angle transmission are essential.

editor by CX 2023-12-01

China Best Sales Galvanized Steel Worm Screw British Type V Band Automotive Hose Clamp for Flexible Hose Pipe near me shop

Product Description

Galvanized Steel Worm Screw British Type V Band Automotive Hose Clamp For Flexible Hose Pipe

Technical Date

| Item No | Range | Band Width | Package |

| MM | MM | Pcs/Carton | |

| FSHY09008 | 8-14 | 9.7 | 2000 |

| FSHY 0571 1 | 11-17 | 9.7 | 2000 |

| FSHY 0571 3 | 13-20 | 9.7 | 2000 |

| FSHY12015 | 15-24 | 11.7 | 500 |

| FSHY12019 | 19-28 | 11.7 | 500 |

| FSHY12571 | 22-32 | 11.7 | 500 |

| FSHY12026 | 26-38 | 11.7 | 500 |

| FSHY12032 | 32-44 | 11.7 | 500 |

| FSHY12038 | 38-50 | 11.7 | 500 |

| FSHY12044 | 44-56 | 11.7 | 500 |

| FSHY12050 | 50-65 | 11.7 | 500 |

| FSHY12058 | 58-75 | 11.7 | 200 |

| FSHY12068 | 68-85 | 11.7 | 200 |

| FSHY12077 | 77-95 | 11.7 | 200 |

| FSHY12087 | 87-112 | 11.7 | 200 |

| FSHY12104 | 104-138 | 11.7 | 100 |

| FSHY12130 | 130-165 | 11.7 | 100 |

| FSHY12150 | 150-180 | 11.7 | 100 |

| FSHY12175 | 175-205 | 11.7 | 100 |

| FSHY12200 | 200-231 | 11.7 | 50 |

| FSHY12226 | 226-256 | 11.7 | 50 |

| FSHY12251 | 251-282 | 11.7 | 50 |

| FSHY12277 | 277-307 | 11.7 | 50 |

W1:Band,housing and screw are all galvanized steel zinc planted

W2:Screw is galvanzied steel zinc plated,band and housing are made of SS304

W4:Band,housing and screw are made of SS 304

W5:Band,housing and screw are made of SS 316

Related Products

Loading

Payment & Shipment

FAQ

Q1:What are the advantages of our factory?

A1:Our factory is specialized in supply pvc hose,irrigation tool and garden tool over 10 years,and our aim is to provide our world-class quality, on-time delivery and excellent after-sales services

Q2:How about our products?

A2:Our products are famous for the good quality and good watering effect,and also you can get the free samples to do a test of the quality and watering effect.

Q3:How about hose specifications?

A3:We can provide PVC hose according to your request on Inner Diameter, working pressure,color and length per roll. Before send you right quotation, please kindly confirm with us.

Q4:How about get the samples?

A4:You can get the samples for free with freight cost collect.We will set by DHL,FEDEX,UPS,TNT,EMS.

Q5:What is the minimum order quantity?(MOQ)

A5:Usually our MOQ is 1000m, but for first cooperation we also accept smaller order.

Q6:How about delivery ?

A6:We can send to you by sea/air/express according to you, usually deliver within 15-20 working days after receive deposit.

Screw Shaft Features Explained

When choosing the screw shaft for your application, you should consider the features of the screws: threads, lead, pitch, helix angle, and more. You may be wondering what these features mean and how they affect the screw’s performance. This article explains the differences between these factors. The following are the features that affect the performance of screws and their properties. You can use these to make an informed decision and purchase the right screw. You can learn more about these features by reading the following articles.

Threads

The major diameter of a screw thread is the larger of the 2 extreme diameters. The major diameter of a screw is also known as the outside diameter. This dimension can’t be directly measured, but can be determined by measuring the distance between adjacent sides of the thread. In addition, the mean area of a screw thread is known as the pitch. The diameter of the thread and pitch line are directly proportional to the overall size of the screw.

The threads are classified by the diameter and pitch. The major diameter of a screw shaft has the largest number of threads; the smaller diameter is called the minor diameter. The thread angle, also known as the helix angle, is measured perpendicular to the axis of the screw. The major diameter is the largest part of the screw; the minor diameter is the lower end of the screw. The thread angle is the half distance between the major and minor diameters. The minor diameter is the outer surface of the screw, while the top surface corresponds to the major diameter.

The pitch is measured at the crest of a thread. In other words, a 16-pitch thread has a diameter of 1 sixteenth of the screw shaft’s diameter. The actual diameter is 0.03125 inches. Moreover, a large number of manufacturers use this measurement to determine the thread pitch. The pitch diameter is a critical factor in successful mating of male and female threads. So, when determining the pitch diameter, you need to check the thread pitch plate of a screw.

Lead

In screw shaft applications, a solid, corrosion-resistant material is an important requirement. Lead screws are a robust choice, which ensure shaft direction accuracy. This material is widely used in lathes and measuring instruments. They have black oxide coatings and are suited for environments where rusting is not acceptable. These screws are also relatively inexpensive. Here are some advantages of lead screws. They are highly durable, cost-effective, and offer high reliability.

A lead screw system may have multiple starts, or threads that run parallel to each other. The lead is the distance the nut travels along the shaft during a single revolution. The smaller the lead, the tighter the thread. The lead can also be expressed as the pitch, which is the distance between adjacent thread crests or troughs. A lead screw has a smaller pitch than a nut, and the smaller the lead, the greater its linear speed.

When choosing lead screws, the critical speed is the maximum number of revolutions per minute. This is determined by the minor diameter of the shaft and its length. The critical speed should never be exceeded or the lead will become distorted or cracked. The recommended operational speed is around 80 percent of the evaluated critical speed. Moreover, the lead screw must be properly aligned to avoid excessive vibrations. In addition, the screw pitch must be within the design tolerance of the shaft.

Pitch

The pitch of a screw shaft can be viewed as the distance between the crest of a thread and the surface where the threads meet. In mathematics, the pitch is equivalent to the length of 1 wavelength. The pitch of a screw shaft also relates to the diameter of the threads. In the following, the pitch of a screw is explained. It is important to note that the pitch of a screw is not a metric measurement. In the following, we will define the 2 terms and discuss how they relate to 1 another.

A screw’s pitch is not the same in all countries. The United Kingdom, Canada, and the United States have standardized screw threads according to the UN system. Therefore, there is a need to specify the pitch of a screw shaft when a screw is being manufactured. The standardization of pitch and diameter has also reduced the cost of screw manufacturing. Nevertheless, screw threads are still expensive. The United Kingdom, Canada, and the United States have introduced a system for the calculation of screw pitch.

The pitch of a lead screw is the same as that of a lead screw. The diameter is 0.25 inches and the circumference is 0.79 inches. When calculating the mechanical advantage of a screw, divide the diameter by its pitch. The larger the pitch, the more threads the screw has, increasing its critical speed and stiffness. The pitch of a screw shaft is also proportional to the number of starts in the shaft.

Helix angle

The helix angle of a screw shaft is the angle formed between the circumference of the cylinder and its helix. Both of these angles must be equal to 90 degrees. The larger the lead angle, the smaller the helix angle. Some reference materials refer to angle B as the helix angle. However, the actual angle is derived from calculating the screw geometry. Read on for more information. Listed below are some of the differences between helix angles and lead angles.

High helix screws have a long lead. This length reduces the number of effective turns of the screw. Because of this, fine pitch screws are usually used for small movements. A typical example is a 16-mm x 5-inch screw. Another example of a fine pitch screw is a 12x2mm screw. It is used for small moves. This type of screw has a lower lead angle than a high-helix screw.

A screw’s helix angle refers to the relative angle of the flight of the helix to the plane of the screw axis. While screw helix angles are not often altered from the standard square pitch, they can have an effect on processing. Changing the helix angle is more common in two-stage screws, special mixing screws, and metering screws. When a screw is designed for this function, it should be able to handle the materials it is made of.

Size

The diameter of a screw is its diameter, measured from the head to the shaft. Screw diameters are standardized by the American Society of Mechanical Engineers. The diameters of screws range from 3/50 inches to 16 inches, and more recently, fractions of an inch have been added. However, shaft diameters may vary depending on the job, so it is important to know the right size for the job. The size chart below shows the common sizes for screws.

Screws are generally referred to by their gauge, which is the major diameter. Screws with a major diameter less than a quarter of an inch are usually labeled as #0 to #14 and larger screws are labeled as sizes in fractions of an inch. There are also decimal equivalents of each screw size. These measurements will help you choose the correct size for your project. The screws with the smaller diameters were not tested.

In the previous section, we described the different shaft sizes and their specifications. These screw sizes are usually indicated by fractions of an inch, followed by a number of threads per inch. For example, a ten-inch screw has a shaft size of 2” with a thread pitch of 1/4″, and it has a diameter of 2 inches. This screw is welded to a two-inch Sch. 40 pipe. Alternatively, it can be welded to a 9-inch O.A.L. pipe.

Shape

Screws come in a wide variety of sizes and shapes, from the size of a quarter to the diameter of a U.S. quarter. Screws’ main function is to hold objects together and to translate torque into linear force. The shape of a screw shaft, if it is round, is the primary characteristic used to define its use. The following chart shows how the screw shaft differs from a quarter:

The shape of a screw shaft is determined by 2 features: its major diameter, or distance from the outer edge of the thread on 1 side to the inner smooth surface of the shaft. These are generally 2 to 16 millimeters in diameter. Screw shafts can have either a fully threaded shank or a half-threaded shank, with the latter providing better stability. Regardless of whether the screw shaft is round or domed, it is important to understand the different characteristics of a screw before attempting to install it into a project.

The screw shaft’s diameter is also important to its application. The ball circle diameter refers to the distance between the center of 2 opposite balls in contact with the grooves. The root diameter, on the other hand, refers to the distance between the bottommost grooves of the screw shaft. These are the 2 main measurements that define the screw’s overall size. Pitch and nominal diameter are important measurements for a screw’s performance in a particular application.

Lubrication

In most cases, lubrication of a screw shaft is accomplished with grease. Grease is made up of mineral or synthetic oil, thickening agent, and additives. The thickening agent can be a variety of different substances, including lithium, bentonite, aluminum, and barium complexes. A common classification for lubricating grease is NLGI Grade. While this may not be necessary when specifying the type of grease to use for a particular application, it is a useful qualitative measure.

When selecting a lubricant for a screw shaft, the operating temperature and the speed of the shaft determine the type of oil to use. Too much oil can result in heat buildup, while too little can lead to excessive wear and friction. The proper lubrication of a screw shaft directly affects the temperature rise of a ball screw, and the life of the assembly. To ensure the proper lubrication, follow the guidelines below.

Ideally, a low lubrication level is appropriate for medium-sized feed stuff factories. High lubrication level is appropriate for larger feed stuff factories. However, in low-speed applications, the lubrication level should be sufficiently high to ensure that the screws run freely. This is the only way to reduce friction and ensure the longest life possible. Lubrication of screw shafts is an important consideration for any screw.

China manufacturer DIN/ANSI/BS/JIS Carbon-Steel/Stainless-Steel 4.8/8.8/10.9 Galvanized Pan Head Word Multi-Colored Screw near me supplier

Product Description

Pan head word multi-colored screw

Screws are generally called wood screws; is the tip of the kind of tip, pitch larger, generally used to tighten wood parts, plastic parts. Mechanical screws, is the front of the kind of screws, the pitch is small, uniform, generally used to fasten the metal, machine parts.Our products has high quality,and long life time.Our company has passed ISO9001, ISO9001 (CQC) certification, product quality assurance.

Screw application range

1> stainless steel plate, metal plate, galvanized steel plate, engineering installation.

2> metal curtain wall metal light compartment and other indoor and outdoor installation.

3> General angle steel, channel steel, iron plate and other metal materials combined installation.

4> car trunk, container box, ship building, refrigeration equipment and other assembly works.

5> automobile engine, heavy machinery, garden machinery, petrochemical.

6> aerospace, energy, machinery, chemical, military, metallurgy, mold, hydraulic.

7> motorcycles, sports equipment, cars and many other industries.

8> electronics, electrical appliances, motors, lighting, communications, home appliances, furniture.

| Brand name | HangZhou | Model | CC-133 | Type | Machine Screw |

| Head Type | Pan head | Groove type | word | Screw diametre | 8mm |

| Screw Length | 105mm | Application | Hand twist | Screw size | M10 |

| Thread tolerance | 6G | Nominal length | 110mm | Surface | multi-color |

Shipping and packaging

Via Ocean shipping

North America, South America about 40 working days

Eastern Europe about 30-40 working days

Southeast Asia about 20-30working days

Africa about 35-45 working days

India, Pakistan about 40 working days

Korea, Japan about 40 working days

Air transport

Other places around 1-3 business days

Packaging: boxes, cartons or plastic bags, or according to customer needs.

Sample service

If you need sample,you need pay the freight.

Customer Service

· 1. No question refund within 3 days.

· 2. Well trained and experienced staffs at your service.

· 3. Short lead time.

· 4. International standard matched

· 5. Non-standard / standard / OEM / ODM / customized service provided.

· 6. Small Quantity available.

· 7. Designed in accordance with customers’ request.

· 8. Packed and delivered by customers’ requirement.

Any more questions or demands, please feel free to contact me!

TEL: -571-668-1767

GB/T 65-2000

GB/T 67-2000

GB/T 68-2000

GB/T 69-2000

GB/T 70.1-200

GB/T 70.2-2000

GB/T 70.3-2000

GB 71-85

GB-72-88

GB-73-85

GB-74-85

GB-75-85

GB/T 77-2000

GB/T 78-2000

GB/T 79-2000

GB/T 80-2000

GB 83-88

GB 84-88

GB 85-88

GB 86-88

GB/T 818-2000

GB 838-88

GB 839-88

GB 840-88

GB 946-88

GB 947-88

GB 948-88

GB 949-88

GB 2672-86

GB 2673-86

GB 2674-86

GB 5281-86

GB/T 820-2000

GB/T 821-88

GB/T 822-2000

GB 823-88

GB 825-88

GB 828-88

GB 829-88

GB 830-88

GB 831-88

GB 832-88

GB 833-88

GB 834-88

GB 835-88

GB 836-88

GB 13-88

GB 14-1998

GB 15-88

GB 29.2-88

GB 35-88

GB 37-88

GB /T794-93

GB 798-88

GB 799-88

GB 800-88

DIN 125-A GB 971-85

DIN 125-B GB97.2-85

DIN127-A GB7244

DIN 127-B GB93-87

DIN 912 GB70-85

DIN933 GB-5783-86

DIN931 GB5782-86

DIN934 GB6170-86

Our factory

Types of Screw Shafts

Screw shafts come in various types and sizes. These types include fully threaded, Lead, and Acme screws. Let’s explore these types in more detail. What type of screw shaft do you need? Which 1 is the best choice for your project? Here are some tips to choose the right screw:

Machined screw shaft

The screw shaft is a basic piece of machinery, but it can be further customized depending on the needs of the customer. Its features include high-precision threads and ridges. Machined screw shafts are generally manufactured using high-precision CNC machines or lathes. The types of screw shafts available vary in shape, size, and material. Different materials are suitable for different applications. This article will provide you with some examples of different types of screw shafts.

Ball screws are used for a variety of applications, including mounting machines, liquid crystal devices, measuring devices, and food and medical equipment. Various shapes are available, including miniature ball screws and nut brackets. They are also available without keyway. These components form a high-accuracy feed mechanism. Machined screw shafts are also available with various types of threaded ends for ease of assembly. The screw shaft is an integral part of linear motion systems.

When you need a machined screw shaft, you need to know the size of the threads. For smaller machine screws, you will need a mating part. For smaller screw sizes, the numbers will be denominated as industry Numeric Sizes. These denominations are not metric, but rather in mm, and they may not have a threads-per-inch designation. Similarly, larger machine screws will usually have threads that have a higher pitch than those with a lower pitch.

Another important feature of machine screws is that they have a thread on the entire shaft, unlike their normal counterparts. These machine screws have finer threads and are intended to be screwed into existing tapped holes using a nut. This means that these screws are generally stronger than other fasteners. They are usually used to hold together electronic components, industrial equipment, and engines. In addition to this, machine screws are usually made of a variety of materials.

Acme screw

An Acme screw is the most common type of threaded shaft available. It is available in a variety of materials including stainless steel and carbon steel. In many applications, it is used for large plates in crushing processes. ACME screws are self-locking and are ideal for applications requiring high clamping force and low friction. They also feature a variety of standard thread forms, including knurling and rolled worms.

Acme screws are available in a wide range of sizes, from 1/8″ to 6″. The diameter is measured from the outside of the screw to the bottom of the thread. The pitch is equal to the lead in a single start screw. The lead is equal to the pitch plus the number of starts. A screw of either type has a standard pitch and a lead. Acme screws are manufactured to be accurate and durable. They are also widely available in a wide range of materials and can be customized to fit your needs.

Another type of Acme screw is the ball screw. These have no back drive and are widely used in many applications. Aside from being lightweight, they are also able to move at faster speeds. A ball screw is similar to an Acme screw, but has a different shape. A ball screw is usually longer than an Acme screw. The ball screw is used for applications that require high linear speeds. An Acme screw is a common choice for many industries.

There are many factors that affect the speed and resolution of linear motion systems. For example, the nut position and the distance the screw travels can all affect the resolution. The total length of travel, the speed, and the duty cycle are all important. The lead size will affect the maximum linear speed and force output. If the screw is long, the greater the lead size, the higher the resolution. If the lead length is short, this may not be the most efficient option.

Lead screw

A lead screw is a threaded mechanical device. A lead screw consists of a cylindrical shaft, which includes a shallow thread portion and a tightly wound spring wire. This spring wire forms smooth, hard-spaced thread convolutions and provides wear-resistant engagement with the nut member. The wire’s leading and trailing ends are anchored to the shaft by means appropriate to the shaft’s composition. The screw is preferably made of stainless steel.

When selecting a lead screw, 1 should first determine its critical speed. The critical speed is the maximum rotations per minute based on the natural frequency of the screw. Excessive backlash will damage the lead screw. The maximum number of revolutions per minute depends on the screw’s minor diameter, length, assembly alignment, and end fixity. Ideally, the critical speed is 80% of its evaluated critical speed. A critical speed is not exceeded because excessive backlash would damage the lead screw and may be detrimental to the screw’s performance.

The PV curve defines the safe operating limits of a lead screw. This relationship describes the inverse relationship between contact surface pressure and sliding velocity. As the PV value increases, a lower rotation speed is required for heavier axial loads. Moreover, PV is affected by material and lubrication conditions. Besides, end fixity, which refers to the way the lead screw is supported, also affects its critical speed. Fixed-fixed and free end fixity are both possible.

Lead screws are widely used in industries and everyday appliances. In fact, they are used in robotics, lifting equipment, and industrial machinery. High-precision lead screws are widely used in the fields of engraving, fluid handling, data storage, and rapid prototyping. Moreover, they are also used in 3D printing and rapid prototyping. Lastly, lead screws are used in a wide range of applications, from measuring to assembly.

Fully threaded screw

A fully threaded screw shaft can be found in many applications. Threading is an important feature of screw systems and components. Screws with threaded shafts are often used to fix pieces of machinery together. Having fully threaded screw shafts ensures that screws can be installed without removing the nut or shaft. There are 2 major types of screw threads: coarse and fine. When it comes to coarse threads, UTS is the most common type, followed by BSP.

In the 1840s, a British engineer named Joseph Whitworth created a design that was widely used for screw threads. This design later became the British Standard Whitworth. This standard was used for screw threads in the United States during the 1840s and 1860s. But as screw threads evolved and international standards were established, this system remained largely unaltered. A new design proposed in 1864 by William Sellers improved upon Whitworth’s screw threads and simplified the pitch and surface finish.

Another reason for using fully threaded screws is their ability to reduce heat. When screw shafts are partially threaded, the bone grows up to the screw shaft and causes the cavity to be too narrow to remove it. Consequently, the screw is not capable of backing out. Therefore, fully threaded screws are the preferred choice for inter-fragmentary compression in children’s fractures. However, surgeons should know the potential complication when removing metalwork.

The full thread depth of a fully threaded screw is the distance at which a male thread can freely thread into the shaft. This dimension is typically 1 millimeter shy of the total depth of the drilled hole. This provides space for tap lead and chips. The full-thread depth also makes fully threaded screws ideal for axially-loaded connections. It is also suitable for retrofitting applications. For example, fully threaded screws are commonly used to connect 2 elements.

Ball screw

The basic static load rating of a ball screw is determined by the product of the maximum axial static load and the safety factor “s0”. This factor is determined by past experience in similar applications and should be selected according to the design requirements of the application. The basic static load rating is a good guideline for selecting a ball screw. There are several advantages to using a ball screw for a particular application. The following are some of the most common factors to consider when selecting a ball screw.

The critical speed limit of a ball screw is dependent on several factors. First of all, the critical speed depends on the mass, length and diameter of the shaft. Second, the deflection of the shaft and the type of end bearings determine the critical speed. Finally, the unsupported length is determined by the distance between the ball nut and end screw, which is also the distance between bearings. Generally, a ball screw with a diameter greater than 1.2 mm has a critical speed limit of 200 rpm.

The first step in manufacturing a high-quality ball screw is the choice of the right steel. While the steel used for manufacturing a ball screw has many advantages, its inherent quality is often compromised by microscopic inclusions. These microscopic inclusions may eventually lead to crack propagation, surface fatigue, and other problems. Fortunately, the technology used in steel production has advanced, making it possible to reduce the inclusion size to a minimum. However, higher-quality steels can be expensive. The best material for a ball screw is vacuum-degassed pure alloy steel.

The lead of a ball screw shaft is also an important factor to consider. The lead is the linear distance between the ball and the screw shaft. The lead can increase the amount of space between the balls and the screws. In turn, the lead increases the speed of a screw. If the lead of a ball screw is increased, it may increase its accuracy. If not, the lead of a ball screw can be improved through preloading, lubrication, and better mounting accuracy.

China OEM Hot Selling Manufacturers Custom Galvanized Worm Gear Brass Gear Worm Gear Shaft Screw near me manufacturer

Product Description

|

Material |

Low carbon steel( 1214, 1215, Y20, Y35), medium carbon steel( S45C, 4140, 4340) / Stainless steeL, 303, 304, 316 / Aluminum 6061, 6063, 7075 / Brass / Bronze / Copper / Titanium / Plastic (POM, PEEK, Nylon, Acrylic, PMMA, PVC, Derlin, ABS, HDEP) And Customized raw material,ect. |

|

Color |

According to customer’s requests |

|

Standard |

ROHS, HE, ISO9000-2008, IGS, TS16949 etc. |

|

Surface treatment |

Heat treatment, polishing electropolishing, plating, electrophresis, black oxide, galvanizing, cold galvanizing, powder coating, paint coating, sand blasting, shot blasting, anodize,passivasion etching,PAD printing, laster carving,dacromet, nickel plating,ect. |

|

Process |

Purchasing raw material / do Inspection on raw material (IQC) / make samples / Inspection samples(QC and engineer) / Sample approvel by customer / Mass production(LQC,PQC) / Surface finish (IQC) / Packing (FQC) / Make Delivery(FQC). |

|

Capabilities |

cnc turning/milling/machining stamping/bending/welding tapping/knurling/Thread hobbing/heading/chamfering Solidworks, STEP, IGS, AutoCAD |

|

Used |

electronics, electrical appliances, furniture, construction, toys, automotive /motorcycle, machinery, kitchen home appliances and other fields |

Screw Shaft Types

A screw shaft is a cylindrical part that turns. Depending on its size, it is able to drive many different types of devices. The following information outlines the different types of screws, including their sizes, material, function, and applications. To help you select the right screw shaft, consider the following factors:

Size

A screw can come in a variety of shapes and sizes, ranging from a quarter to a quarter-inch in diameter. A screw is a cylindrical shaft with an inclined plane wrapped around it, and its main function is to fasten objects together by translating torque into a linear force. This article will discuss the dimensions of screws and how to determine the size of a screw. It is important to note that screw sizes can be large and small depending on the purpose.

The diameter of a screw is the diameter of its shaft, and it must match the inner diameter of its nuts and washers. Screws of a certain diameter are also called machine screws, and they can be larger or smaller. Screw diameters are measured on the shaft underneath the screw head. The American Society of Mechanical Engineers (ASME) standardized screw diameters in 3/50-inch to 16 (3/8-inch) inches, and more recently, sizes were added in U.S. fractions of an inch. While shaft and head diameters are standardized, screw length may vary from job to job.

In the case of the 2.3-mm screw group, the construct strength was not improved by the 1.2-mm group. The smaller screw size did not increase the strength of the construct. Further, ABS material did not improve the construct strength. Thus, the size of screw shaft is an important consideration in model design. And remember that the more complex your model is, the larger it will be. A screw of a given size will have a similar failure rate as a screw of a different diameter.

Although different screw sizes are widely used, the differences in screw size were not statistically significant. Although there are some limitations, screws of different sizes are generally sufficient for fixation of a metacarpal shaft fracture. However, further clinical studies are needed to compare screw sizes for fracture union rates. So, if you are unsure of what size of screw shaft you need for your case, make sure to check the metric chart and ensure you use the right one.

Material

The material of a screw shaft plays an important role in the overall performance of a screw. Axial and central forces act to apply torque to the screw, while external forces, such as friction, exert a bending moment. The torsional moments are reflected in the torque, and this causes the screw to rotate at a higher rate than necessary. To ensure the longevity of the screw, the material of the screw shaft should be able to handle the bending moment, while the diameter of the shaft should be small enough to avoid causing damage.

Screws are made from different metals, such as steel, brass, titanium, and bronze. Manufacturers often apply a top coating of chromium, brass, or zinc to improve corrosion resistance. Screws made of aluminum are not durable and are prone to rusting due to exposure to weather conditions. The majority of screw shafts are self-locking. They are suited for many applications, including threaded fasteners, C-clamps, and vises.

Screws that are fabricated with conical sections typically feature reduced open cross-sectional areas at the discharge point. This is a key design parameter of conical screw shafts. In fact, reductions of up to 72% are common across a variety of applications. If the screw is designed to have a hard-iron hanger bearing, it must be hardened. If the screw shaft is not hardened, it will require an additional lubricant.

Another consideration is the threads. Screw shafts are typically made of high-precision threads and ridges. These are manufactured on lathes and CNC machines. Different shapes require different materials. Materials for the screw shaft vary. There are many different sizes and shapes available, and each 1 has its own application. In addition to helical and conical screw shafts, different materials are also available. When choosing material, the best 1 depends on the application.

The life of the screw depends on its size, load, and design. In general, the material of the screw shaft, nut body, and balls and rollers determine its fatigue life. This affects the overall life of the screw. To determine whether a specific screw has a longer or shorter life, the manufacturer must consider these factors, as well as the application requirements. The material should be clean and free of imperfections. It should be smooth and free of cracks or flaking, which may result in premature failure.

Function

The function of a screw shaft is to facilitate the rotation of a screw. Screws have several thread forms, including single-start, double-start and multi-start. Each form has its own advantages and disadvantages. In this article we’ll explore each of them in detail. The function of a screw shaft can vary based on its design, but the following are common types. Here are some examples of screw shaft types and their purposes.

The screw’s torque enables it to lift objects. It can be used in conjunction with a bolt and nut to lift a load. Screws are also used to secure objects together. You can use them in screw presses, vises, and screw jacks. But their primary function is to hold objects together. Listed below are some of their main functions. When used to lift heavy loads, they can provide the required force to secure an object.

Screws can be classified into 2 types: square and round. Square threads are more efficient than round ones because they apply 0deg of angle to the nut. Square threads are also stronger than round threads and are often used in high-load applications. They’re generally cheaper to manufacture and are more difficult to break. And unlike square threads, which have a 0deg thread angle, these threads can’t be broken easily with a screwdriver.

A screw’s head is made of a series of spiral-like structures that extend from a cylindrical part to a tip. This portion of the screw is called the shank and is made of the smallest area. The shank is the portion that applies more force to the object. As the shaft extends from the head, it becomes thinner and narrow, forming a pointed tip. The head is the most important part of the screw, so it needs to be strong to perform its function.

The diameter of the screw shaft is measured in millimeters. The M8 screw has a thread pitch of 1.25 mm. Generally, the size of the screw shaft is indicated by the major and minor diameter. These dimensions are appended with a multiplication sign (M8x1).

Applications

The design of screws, including their size and shape, determines their critical rotating speeds. These speeds depend on the threaded part of the screw, the helix angle, and the geometry of the contact surfaces. When applied to a screw, these limits are referred to as “permissible speed limits.” These maximum speeds are meant for short periods of time and optimized running conditions. Continuous operation at these speeds can reduce the calculated life of a nut mechanism.

The main materials used to manufacture screws and screw shafts include steel, stainless steel, titanium, bronze, and brass. Screws may be coated for corrosion resistance, or they may be made of aluminium. Some materials can be threaded, including Teflon and nylon. Screw threads can even be molded into glass or porcelain. For the most part, steel and stainless steel are the most common materials for screw shafts. Depending on the purpose, a screw will be made of a material that is suitable for the application.

In addition to being used in fasteners, screw shafts are used in micrometers, drillers, conveyor belts, and helicopter blades. There are numerous applications of screw shafts, from weighing scales to measuring lengths. If you’re in the market for a screw, make sure to check out these applications. You’ll be happy you did! They can help you get the job done faster. So, don’t delay your next project.

If you’re interested in learning about screw sizing, then it’s important to know the axial and moment loads that your screws will experience. By following the laws of mechanics and knowing the load you can calculate the nominal life of your screw. You can also consider the effect of misalignment, uneven loading, and shocks on your screw. These will all affect the life of your screw. Then, you can select the right screw.