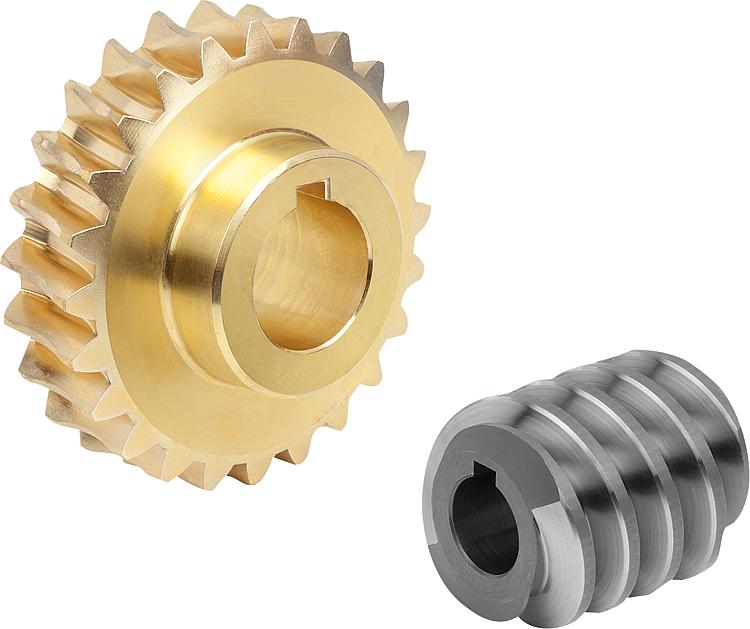

Product Description

You can kindly find the specification details below:

HangZhou Mastery Machinery Technology Co., LTD helps manufacturers and brands fulfill their machinery parts by precision manufacturing. High precision machinery products like the shaft, worm screw, bushing, couplings, joints……Our products are used widely in electronic motors, the main shaft of the engine, the transmission shaft in the gearbox, couplers, printers, pumps, drones, and so on. They cater to different industries, including automotive, industrial, power tools, garden tools, healthcare, smart home, etc.

Mastery caters to the industrial industry by offering high-level Cardan shafts, pump shafts, and a bushing that come in different sizes ranging from diameter 3mm-50mm. Our products are specifically formulated for transmissions, robots, gearboxes, industrial fans, and drones, etc.

Mastery factory currently has more than 100 main production equipment such as CNC lathe, CNC machining center, CAM Automatic Lathe, grinding machine, hobbing machine, etc. The production capacity can be up to 5-micron mechanical tolerance accuracy, automatic wiring machine processing range covering 3mm-50mm diameter bar.

Key Specifications:

| Name | Shaft/Motor Shaft/Drive Shaft/Gear Shaft/Pump Shaft/Worm Screw/Worm Gear/Bushing/Ring/Joint/Pin |

| Material | 40Cr/35C/GB45/70Cr/40CrMo |

| Process | Machining/Lathing/Milling/Drilling/Grinding/Polishing |

| Size | 2-400mm(Customized) |

| Diameter | φ12(Customized) |

| Diameter Tolerance | 0.015mm |

| Roundness | 0.01mm |

| Roughness | Ra0.2-0.6 |

| Straightness | 0.01mm |

| Hardness | Customized |

| Length | 153mm(Customized) |

| Heat Treatment | Customized |

| Surface treatment | Coating/Ni plating/Zn plating/QPQ/Carbonization/Quenching/Black Treatment/Steaming Treatment/Nitrocarburizing/Carbonitriding |

Quality Management:

- Raw Material Quality Control: Chemical Composition Analysis, Mechanical Performance Test, ROHS, and Mechanical Dimension Check

- Production Process Quality Control: Full-size inspection for the 1st part, Critical size process inspection, SPC process monitoring

- Lab ability: CMM, OGP, XRF, Roughness meter, Profiler, Automatic optical inspector

- Quality system: ISO9001, IATF 16949, ISO14001

- Eco-Friendly: ROHS, Reach.

Packaging and Shipping:

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business.

Mastery utilizes several different shipping methods that are detailed below:

For Samples/Small Q’ty: By Express Services or Air Fright.

For Formal Order: By Sea or by air according to your requirement.

Mastery Services:

- One-Stop solution from idea to product/ODM&OEM acceptable

- Individual research and sourcing/purchasing tasks

- Individual supplier management/development, on-site quality check projects

- Muti-varieties/small batch/customization/trial orders are acceptable

- Flexibility on quantity/Quick samples

- Forecast and raw material preparation in advance are negotiable

- Quick quotes and quick responses

General Parameters:

If you are looking for a reliable machinery product partner, you can rely on Mastery. Work with us and let us help you grow your business using our customizable and affordable products. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

|

|

|---|

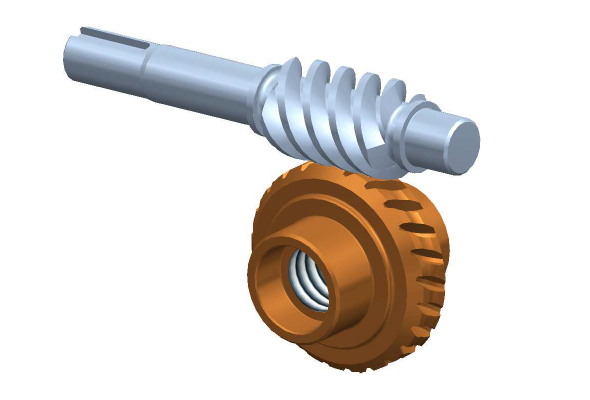

How do you properly lubricate a worm screw and gear assembly?

Proper lubrication is essential for the smooth and efficient operation of a worm screw and gear assembly. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, thereby extending the lifespan of the components. Here are the steps to properly lubricate a worm screw and gear assembly:

- Clean the Assembly: Before applying lubrication, ensure that the worm screw and gear assembly is free from dirt, debris, and old lubricant residues. Clean the surfaces using an appropriate cleaning agent or solvent, followed by a thorough drying process.

- Select the Right Lubricant: Choose a lubricant specifically designed for gear systems or worm screw applications. Consider factors such as viscosity, temperature range, load capacity, and compatibility with the materials used in the assembly. Consult the manufacturer’s recommendations or lubrication guidelines for the specific assembly to determine the suitable lubricant type and grade.

- Apply the Lubricant: Apply the lubricant to the contacting surfaces of the worm screw and gear assembly. Use an appropriate applicator, such as a brush, oil can, or grease gun, depending on the lubricant form (oil or grease) and the accessibility of the components. Ensure complete coverage of the gear teeth, worm screw threads, and other relevant surfaces. Pay attention to areas where the most significant friction and wear occur.

- Monitor the Lubricant Level: Check the lubricant level regularly to ensure an adequate supply. Depending on the application and operating conditions, lubricant consumption or degradation may occur over time. It is important to maintain the lubricant level within the recommended range to ensure proper lubrication and prevent excessive wear or overheating.

- Periodic Lubrication Maintenance: Establish a lubrication maintenance schedule based on the operating conditions and manufacturer’s recommendations. Regularly inspect the assembly for signs of lubricant degradation, contamination, or insufficient lubrication. Replace the lubricant as needed and follow the recommended intervals for lubricant replenishment or reapplication.

- Consideration for Grease Lubrication: If using grease as the lubricant, it is important to choose a high-quality grease suitable for worm screw applications. Grease provides better adhesion to surfaces and tends to stay in place, offering longer-lasting lubrication compared to oil. However, excessive grease accumulation or over-greasing should be avoided, as it can lead to increased friction and inefficiency.

It is crucial to follow the manufacturer’s guidelines and recommendations for lubrication specific to the worm screw and gear assembly. Different assemblies may have unique lubrication requirements based on their design, load capacity, operating conditions, and materials used. By properly lubricating the worm screw and gear assembly, you can ensure optimal performance, reduce wear, and extend the operational life of the components.

What are the latest innovations in worm screw design and materials?

In recent years, there have been several notable innovations in worm screw design and materials that aim to improve performance, efficiency, durability, and overall functionality. Here are some of the latest advancements in this field:

- Advanced Materials: One of the significant trends in worm screw design is the use of advanced materials. Manufacturers are exploring materials with enhanced strength, wear resistance, and fatigue properties. For example, advanced alloys and composite materials are being employed to improve load capacity, reduce weight, and increase the longevity of worm screws. Additionally, advancements in material science and engineering are leading to the development of self-lubricating materials, which can minimize friction and improve efficiency by reducing the need for external lubrication.

- Improved Thread Geometries: Innovations in thread geometries have focused on optimizing load distribution, reducing friction, and improving efficiency. Researchers and engineers are developing novel thread profiles and forms that enhance contact between the worm screw and the worm wheel. These designs help minimize backlash, increase load-carrying capacity, and improve overall system performance. Additionally, advancements in computer simulations and modeling techniques enable more accurate analysis and optimization of thread geometries for specific applications.

- Surface Treatments and Coatings: Surface treatments and coatings are being applied to worm screws to enhance their performance and durability. For instance, advanced coatings such as diamond-like carbon (DLC) coatings or specialized lubricious coatings help reduce friction, improve wear resistance, and minimize the need for external lubrication. Surface treatments like nitriding or carburizing can improve hardness and provide resistance against abrasive wear, increasing the lifespan of worm screws.

- Precision Manufacturing: Innovations in manufacturing processes and technologies have enabled the production of worm screws with higher precision and tighter tolerances. Advanced machining techniques, such as CNC grinding and high-precision gear hobbing, allow for the creation of worm screws with superior dimensional accuracy, improved surface finish, and better tooth profile control. These manufacturing advancements contribute to enhanced performance, reduced backlash, and increased overall system efficiency.

- Computer-Aided Design and Simulation: The use of computer-aided design (CAD) software and simulation tools has revolutionized worm screw design and optimization. Engineers can now create virtual models, simulate the behavior of worm gear systems, and analyze various design parameters to optimize performance before physical prototypes are manufactured. This iterative design process helps reduce development time, minimize costs, and improve the final design and performance of worm screws.

- Integration with Digitalization and Automation: The integration of worm gear systems with digitalization and automation technologies is another area of innovation. Worm screws are being designed to work seamlessly with sensor technologies, allowing for real-time monitoring of performance parameters such as temperature, vibration, and load. This data can be utilized for predictive maintenance, condition monitoring, and optimization of the overall system performance.

It’s important to note that the field of worm screw design and materials is continuously evolving, and new innovations are being introduced regularly. Keeping up with the latest research, advancements, and industry developments is crucial for engineers, designers, and manufacturers involved in worm gear system applications.

How do you calculate the gear ratio for a worm screw and gear setup?

In a worm screw and gear setup, the gear ratio is determined by the number of teeth on the worm wheel (gear) and the number of threads on the worm screw. The gear ratio represents the relationship between the rotational speed of the worm screw and the resulting rotational speed of the worm wheel. The formula to calculate the gear ratio is as follows:

Gear Ratio = Number of Teeth on Worm Wheel / Number of Threads on Worm Screw

Here’s a step-by-step process to calculate the gear ratio:

- Count the number of teeth on the worm wheel. This can be done by visually inspecting the gear or referring to its specifications.

- Count the number of threads on the worm screw. The threads refer to the number of complete turns or helical grooves wrapped around the cylindrical body of the worm screw.

- Divide the number of teeth on the worm wheel by the number of threads on the worm screw.

- The result of the division is the gear ratio. It represents the number of revolutions of the worm screw required to complete one revolution of the worm wheel.

For example, let’s say the worm wheel has 40 teeth, and the worm screw has 2 threads. Using the formula, we can calculate the gear ratio as follows:

Gear Ratio = 40 teeth / 2 threads = 20

In this case, for every full revolution of the worm screw, the worm wheel will rotate 1/20th of a revolution. This indicates a significant speed reduction, resulting in high torque output at the worm wheel.

It’s important to note that the gear ratio calculated using this formula assumes an ideal scenario without considering factors like friction, efficiency losses, or the pitch diameter of the gears. In practical applications, these factors may affect the actual gear ratio and performance of the worm screw and gear setup.

editor by CX 2024-01-11

China Custom High Precision 6.35X124 Stepped Worm Motor Rotor Steel Shaft near me supplier

Product Description

| Material: | Stainless Steel, aluminum, Aluminium,steel ,stainless steel,brass |

| Brand Name: | OEM |

| Size in metric: | M2.5, M3, M4, M5, M6, M8, M10, 4-40, 6-32, 8-32, 10-32 |

| Application: | model airplane,computer,RC Helicopter |

| OEM&ODM: | YES |

| Certificate: | ISO9001, ISO14001 |

| Color: | Plain aluminium , black, red, etc |

| Place of Origin: | ZheJiang , China |

| Product name: | Fastener, Screw, Bolts, Nut, Insert, Standoff, Pin, Stud |

| Thread type: | male threaded |

| Plating: | Sand blast and Anodized |

| Supply Ability: | 6000000 Piece/Pieces per Month |

| Packaging Details: | Into PP bag, then into carton box packed |

| Port: | HangZhou |

| Standard: | ISO, JIS, GB, ANSI, BSW, DIN or non standard as customized |

| Material: | 1. Stainless Steel: SUS303, SUS304, SUS316, SUS410, SUS420 2. Steel: C45(K1045), C46(K1046), C20 3. Brass: C36000(C26800), C37700(HPb59), C38500(HPb58),C27200(CuZn37), C28000(CuZn40), C2700, C3604, HBi59-1 4. Bronze: C51000, C52100, C54400, etc 5. Iron: 1213, 12L14,1215 6. Aluminum/ Aluminum Alloy: Al6061, Al6063 etc 7. Carbon steel: C1006, C1571, C1018, C1571, C1035K, C1045, C435#, 40CrMo, 42CrMo 8. Alloy steel: SCM435,10B21 9. Titanium and Titanium Alloy: TAD, TA1-TA8, TB2, TC1-TC10 |

| Grade: | 4.8,6.8,8.8,12.9 |

| Size: | M2~M12 |

| Specifications: | Various shape size according to client’s requirement |

| Thread: | unc,unf,metric thread |

| Finish: | Plain, Zinc Plated(Clear/Blue/Yellow/Black), black oxide, H.D.G, DAC,GOEMET, as custom need |

| Payment term: | T/T 30% deposit and 70% balance payment before shipment |

| Package: | solid cardboard box pack or kit packed |

| Company Profile

Our company was established in 2016, located at Dalang Town, HangZhou City, ZheJiang Province. It is mainly engaged in the development, production and sales of various types of precision metal parts in appearance and function. The operation mode of our company is leading by the marketing, focus on technology as well as the production guarantee, to provide a one-stop service from research and development, manufacturing and delivery of the after-sales service to customers. Our company offers variety of products which can meet your multifarious demands. We adhere to the management principles of “quality first, customer first and credit-based” since the establishment of the company and always do our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a CZPT situation since the trend of economic globalization has developed with anirresistible force. |

Screw Shaft Features Explained

When choosing the screw shaft for your application, you should consider the features of the screws: threads, lead, pitch, helix angle, and more. You may be wondering what these features mean and how they affect the screw’s performance. This article explains the differences between these factors. The following are the features that affect the performance of screws and their properties. You can use these to make an informed decision and purchase the right screw. You can learn more about these features by reading the following articles.

Threads

The major diameter of a screw thread is the larger of the 2 extreme diameters. The major diameter of a screw is also known as the outside diameter. This dimension can’t be directly measured, but can be determined by measuring the distance between adjacent sides of the thread. In addition, the mean area of a screw thread is known as the pitch. The diameter of the thread and pitch line are directly proportional to the overall size of the screw.

The threads are classified by the diameter and pitch. The major diameter of a screw shaft has the largest number of threads; the smaller diameter is called the minor diameter. The thread angle, also known as the helix angle, is measured perpendicular to the axis of the screw. The major diameter is the largest part of the screw; the minor diameter is the lower end of the screw. The thread angle is the half distance between the major and minor diameters. The minor diameter is the outer surface of the screw, while the top surface corresponds to the major diameter.

The pitch is measured at the crest of a thread. In other words, a 16-pitch thread has a diameter of 1 sixteenth of the screw shaft’s diameter. The actual diameter is 0.03125 inches. Moreover, a large number of manufacturers use this measurement to determine the thread pitch. The pitch diameter is a critical factor in successful mating of male and female threads. So, when determining the pitch diameter, you need to check the thread pitch plate of a screw.

Lead

In screw shaft applications, a solid, corrosion-resistant material is an important requirement. Lead screws are a robust choice, which ensure shaft direction accuracy. This material is widely used in lathes and measuring instruments. They have black oxide coatings and are suited for environments where rusting is not acceptable. These screws are also relatively inexpensive. Here are some advantages of lead screws. They are highly durable, cost-effective, and offer high reliability.

A lead screw system may have multiple starts, or threads that run parallel to each other. The lead is the distance the nut travels along the shaft during a single revolution. The smaller the lead, the tighter the thread. The lead can also be expressed as the pitch, which is the distance between adjacent thread crests or troughs. A lead screw has a smaller pitch than a nut, and the smaller the lead, the greater its linear speed.

When choosing lead screws, the critical speed is the maximum number of revolutions per minute. This is determined by the minor diameter of the shaft and its length. The critical speed should never be exceeded or the lead will become distorted or cracked. The recommended operational speed is around 80 percent of the evaluated critical speed. Moreover, the lead screw must be properly aligned to avoid excessive vibrations. In addition, the screw pitch must be within the design tolerance of the shaft.

Pitch

The pitch of a screw shaft can be viewed as the distance between the crest of a thread and the surface where the threads meet. In mathematics, the pitch is equivalent to the length of 1 wavelength. The pitch of a screw shaft also relates to the diameter of the threads. In the following, the pitch of a screw is explained. It is important to note that the pitch of a screw is not a metric measurement. In the following, we will define the 2 terms and discuss how they relate to 1 another.

A screw’s pitch is not the same in all countries. The United Kingdom, Canada, and the United States have standardized screw threads according to the UN system. Therefore, there is a need to specify the pitch of a screw shaft when a screw is being manufactured. The standardization of pitch and diameter has also reduced the cost of screw manufacturing. Nevertheless, screw threads are still expensive. The United Kingdom, Canada, and the United States have introduced a system for the calculation of screw pitch.

The pitch of a lead screw is the same as that of a lead screw. The diameter is 0.25 inches and the circumference is 0.79 inches. When calculating the mechanical advantage of a screw, divide the diameter by its pitch. The larger the pitch, the more threads the screw has, increasing its critical speed and stiffness. The pitch of a screw shaft is also proportional to the number of starts in the shaft.

Helix angle

The helix angle of a screw shaft is the angle formed between the circumference of the cylinder and its helix. Both of these angles must be equal to 90 degrees. The larger the lead angle, the smaller the helix angle. Some reference materials refer to angle B as the helix angle. However, the actual angle is derived from calculating the screw geometry. Read on for more information. Listed below are some of the differences between helix angles and lead angles.

High helix screws have a long lead. This length reduces the number of effective turns of the screw. Because of this, fine pitch screws are usually used for small movements. A typical example is a 16-mm x 5-inch screw. Another example of a fine pitch screw is a 12x2mm screw. It is used for small moves. This type of screw has a lower lead angle than a high-helix screw.

A screw’s helix angle refers to the relative angle of the flight of the helix to the plane of the screw axis. While screw helix angles are not often altered from the standard square pitch, they can have an effect on processing. Changing the helix angle is more common in two-stage screws, special mixing screws, and metering screws. When a screw is designed for this function, it should be able to handle the materials it is made of.

Size

The diameter of a screw is its diameter, measured from the head to the shaft. Screw diameters are standardized by the American Society of Mechanical Engineers. The diameters of screws range from 3/50 inches to 16 inches, and more recently, fractions of an inch have been added. However, shaft diameters may vary depending on the job, so it is important to know the right size for the job. The size chart below shows the common sizes for screws.

Screws are generally referred to by their gauge, which is the major diameter. Screws with a major diameter less than a quarter of an inch are usually labeled as #0 to #14 and larger screws are labeled as sizes in fractions of an inch. There are also decimal equivalents of each screw size. These measurements will help you choose the correct size for your project. The screws with the smaller diameters were not tested.

In the previous section, we described the different shaft sizes and their specifications. These screw sizes are usually indicated by fractions of an inch, followed by a number of threads per inch. For example, a ten-inch screw has a shaft size of 2” with a thread pitch of 1/4″, and it has a diameter of 2 inches. This screw is welded to a two-inch Sch. 40 pipe. Alternatively, it can be welded to a 9-inch O.A.L. pipe.

Shape

Screws come in a wide variety of sizes and shapes, from the size of a quarter to the diameter of a U.S. quarter. Screws’ main function is to hold objects together and to translate torque into linear force. The shape of a screw shaft, if it is round, is the primary characteristic used to define its use. The following chart shows how the screw shaft differs from a quarter:

The shape of a screw shaft is determined by 2 features: its major diameter, or distance from the outer edge of the thread on 1 side to the inner smooth surface of the shaft. These are generally 2 to 16 millimeters in diameter. Screw shafts can have either a fully threaded shank or a half-threaded shank, with the latter providing better stability. Regardless of whether the screw shaft is round or domed, it is important to understand the different characteristics of a screw before attempting to install it into a project.

The screw shaft’s diameter is also important to its application. The ball circle diameter refers to the distance between the center of 2 opposite balls in contact with the grooves. The root diameter, on the other hand, refers to the distance between the bottommost grooves of the screw shaft. These are the 2 main measurements that define the screw’s overall size. Pitch and nominal diameter are important measurements for a screw’s performance in a particular application.

Lubrication

In most cases, lubrication of a screw shaft is accomplished with grease. Grease is made up of mineral or synthetic oil, thickening agent, and additives. The thickening agent can be a variety of different substances, including lithium, bentonite, aluminum, and barium complexes. A common classification for lubricating grease is NLGI Grade. While this may not be necessary when specifying the type of grease to use for a particular application, it is a useful qualitative measure.

When selecting a lubricant for a screw shaft, the operating temperature and the speed of the shaft determine the type of oil to use. Too much oil can result in heat buildup, while too little can lead to excessive wear and friction. The proper lubrication of a screw shaft directly affects the temperature rise of a ball screw, and the life of the assembly. To ensure the proper lubrication, follow the guidelines below.

Ideally, a low lubrication level is appropriate for medium-sized feed stuff factories. High lubrication level is appropriate for larger feed stuff factories. However, in low-speed applications, the lubrication level should be sufficiently high to ensure that the screws run freely. This is the only way to reduce friction and ensure the longest life possible. Lubrication of screw shafts is an important consideration for any screw.