Product Description

GLR Series Single Nut Ball Screw with Metric Thread (C5/Ct7/Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of GLR series(single nut ball screw with metric thread)are based on C5,Ct7 and Ct10(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5),0.02(Ct7) and 0.05mm or less(Ct10).

Material & Surface Hardness

GLR series (single nut ball screw with metric thread)of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shaft end shape of the GLR series (single nut ball screw with metric thread) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5 |

|---|---|

| Screw Diameter: | 8mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 3-Row |

| Nut Type: | Single Nut Ball Screw with Metric Thread |

| Customization: |

Available

|

|

|---|

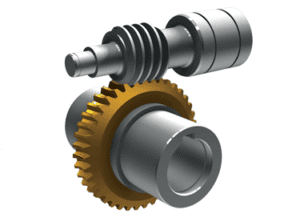

What are the common issues or failures associated with worm screws?

Worm screws, like any mechanical component, can experience certain issues or failures over time. Understanding these common problems is important for proper maintenance and troubleshooting. Here are some common issues or failures associated with worm screws:

- Wear and Surface Damage: Due to the sliding contact between the threads of the worm screw and the teeth of the worm wheel, wear can occur over time. This wear can lead to surface damage, such as pitting, scoring, or galling. Excessive wear and surface damage can affect the performance and efficiency of the worm screw gear system, resulting in increased backlash, decreased torque transmission, and potential failure.

- Lubrication Problems: Inadequate or improper lubrication is a common cause of issues in worm screw systems. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear. On the other hand, over-lubrication can cause excessive drag and fluid churn, leading to inefficient power transmission. It is important to follow the manufacturer’s recommendations for lubrication intervals, types of lubricants, and proper lubrication techniques to ensure optimal performance and longevity of the worm screw system.

- Backlash and Inaccuracy: Backlash refers to the play or clearance between the threads of the worm screw and the teeth of the worm wheel. Excessive backlash can result in reduced accuracy, loss of motion control, and diminished overall system performance. Backlash can be caused by factors such as wear, misalignment, or improper assembly. Regular inspection and adjustment of backlash are necessary to maintain the desired precision and minimize the effects of backlash-related issues.

- Misalignment: Misalignment between the worm screw and the worm wheel can result in increased friction, wear, and inefficiencies. Misalignment can occur due to factors such as improper installation, component deformation, or external forces. It is essential to ensure proper alignment during installation and periodically check for misalignment during routine maintenance. Adjustments should be made as necessary to maintain optimal performance and prevent premature failure.

- Overloading: Subjecting the worm screw gear system to excessive loads beyond its design limits can lead to failure. Overloading can result in accelerated wear, tooth breakage, or component deformation. It is important to operate the system within the specified load limits and consider factors such as shock loads, dynamic loads, and variations in operating conditions. If higher loads are required, it may be necessary to select a worm screw system with a higher load capacity or redesign the system accordingly.

- Corrosion and Contamination: Corrosion and contamination can negatively impact the performance and lifespan of worm screw systems. Exposure to moisture, chemicals, or abrasive particles can lead to corrosion, rusting, or damage to the surfaces of the worm screw and worm wheel. Contamination can interfere with smooth operation and cause accelerated wear. Proper environmental protection, regular cleaning, and appropriate sealing measures can help mitigate the effects of corrosion and contamination.

- Insufficient Stiffness: Worm screws rely on proper support and stiffness to maintain accurate positioning and prevent deflection. Inadequate stiffness in the supporting structure or mounting arrangement can result in excessive deflection, misalignment, and decreased performance. It is crucial to ensure that the worm screw system is properly supported and mounted to maintain the required rigidity and stiffness for optimal operation.

It’s important to note that the specific issues or failures associated with worm screws can vary depending on factors such as the application, operating conditions, maintenance practices, and the quality of the components. Regular inspection, proper lubrication, alignment checks, load monitoring, and adherence to manufacturer guidelines are essential for minimizing the occurrence of these issues and ensuring the reliable and efficient operation of worm screw systems.

Can worm screws be customized for specific engineering needs?

Yes, worm screws can be customized to meet specific engineering needs and application requirements. Customization allows for tailoring the design, dimensions, materials, and other parameters of the worm screw to optimize its performance and functionality. Here are some aspects of worm screws that can be customized:

- Thread Geometry: The thread geometry of a worm screw can be customized to suit specific requirements. This includes the shape, profile, lead angle, and thread form. Custom thread geometries can be designed to optimize load distribution, minimize friction, reduce backlash, improve efficiency, or achieve specific performance characteristics.

- Pitch and Lead: The pitch and lead of a worm screw can be tailored to meet the desired gear ratio, output speed, load capacity, and other performance criteria. Customizing the pitch and lead allows for precise control over the speed reduction or multiplication capabilities of the worm gear system.

- Materials: Worm screws can be customized to be made from different materials based on the specific application requirements. Common materials include steel, stainless steel, bronze, and various alloys. The choice of material depends on factors such as load capacity, durability, corrosion resistance, temperature tolerance, and other environmental considerations.

- Diameter and Length: The diameter and length of a worm screw can be customized to suit the mechanical constraints and dimensional requirements of the application. Custom sizing ensures proper fit, alignment, and integration within the overall system design.

- Coatings and Surface Treatments: Custom coatings or surface treatments can be applied to worm screws to enhance their performance and durability. These can include treatments such as hardening, heat treatment, plating, or specialized coatings to improve wear resistance, reduce friction, or provide corrosion protection.

- Special Features: Worm screws can be customized to incorporate special features or modifications based on specific engineering needs. This may include the addition of keyways, flanges, shaft extensions, or other components to facilitate integration with other system elements or to accommodate unique mechanical requirements.

Customization of worm screws requires collaboration between engineers, designers, and manufacturers with expertise in worm gear systems. It is important to define the specific engineering needs, performance requirements, and operational conditions to ensure that the customized worm screw meets the desired objectives effectively.

How does a worm screw differ from a regular screw?

In mechanical engineering, a worm screw differs from a regular screw in several key aspects. While both types of screws have helical threads, their designs and functions are distinct. Here are the primary differences between a worm screw and a regular screw:

- Motion Transmission: The primary function of a regular screw is to convert rotary motion into linear motion or vice versa. It typically has a single-threaded or multi-threaded configuration and is used for applications such as fastening, clamping, or lifting. On the other hand, a worm screw is designed to transmit motion and power between non-parallel shafts. It converts rotary motion along its axis into rotary motion perpendicular to its axis by meshing with a worm wheel or gear.

- Gear Ratio: The gear ratio of a worm screw is typically much higher compared to that of a regular screw. The helical teeth of the worm screw and the worm wheel allow for a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a significant rotation of the worm wheel. In contrast, a regular screw does not have a gear ratio and is primarily used for linear motion or force multiplication.

- Orientation and Shaft Arrangement: A regular screw is typically used in applications where the input and output shafts are parallel or nearly parallel. It transfers motion and force along the same axis. In contrast, a worm screw is designed for applications where the input and output shafts are perpendicular to each other. The orientation of the worm screw and the worm wheel allows for motion transmission between non-parallel shafts.

- Self-Locking: One distinctive characteristic of a worm screw is its self-locking property. The helical teeth of the worm screw create a wedging effect that prevents the worm wheel from driving the worm screw. This self-locking feature allows worm screws to hold loads without the need for additional braking mechanisms. Regular screws, on the other hand, do not have this self-locking capability.

- Applications: Regular screws find widespread use in numerous applications, including construction, manufacturing, woodworking, and everyday objects like screws used in fastening. They are primarily employed for linear motion, clamping, or force multiplication. Worm screws, on the other hand, are commonly used in applications that require significant speed reduction, torque multiplication, or motion transmission at right angles. Typical applications include conveyor systems, winches, lifting mechanisms, and heavy machinery.

These differences in design and function make worm screws and regular screws suitable for distinct applications. Regular screws are more commonly used for linear motion and force transfer along parallel or nearly parallel shafts, while worm screws excel in transmitting motion and power between non-parallel shafts with high gear reduction ratios.

editor by CX 2024-04-09