Product Description

GLR Series Single Nut Ball Screw with Metric Thread (C5/Ct7/Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of GLR series(single nut ball screw with metric thread)are based on C5,Ct7 and Ct10(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5),0.02(Ct7) and 0.05mm or less(Ct10).

Material & Surface Hardness

GLR series (single nut ball screw with metric thread)of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shaft end shape of the GLR series (single nut ball screw with metric thread) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Screw Diameter: | 8mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 3-Row |

| Nut Type: | Single Nut Ball Screw with Metric Thread |

| Customization: |

Available

|

|

|---|

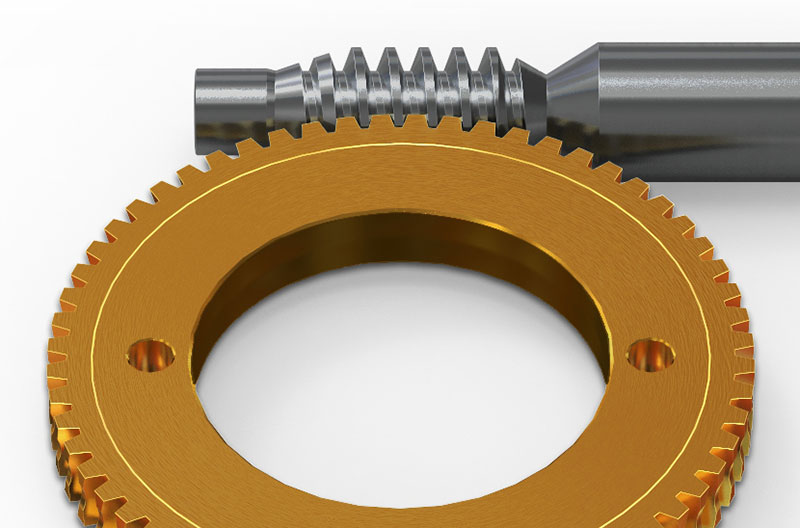

What are the common issues or failures associated with worm screws?

Worm screws, like any mechanical component, can experience certain issues or failures over time. Understanding these common problems is important for proper maintenance and troubleshooting. Here are some common issues or failures associated with worm screws:

- Wear and Surface Damage: Due to the sliding contact between the threads of the worm screw and the teeth of the worm wheel, wear can occur over time. This wear can lead to surface damage, such as pitting, scoring, or galling. Excessive wear and surface damage can affect the performance and efficiency of the worm screw gear system, resulting in increased backlash, decreased torque transmission, and potential failure.

- Lubrication Problems: Inadequate or improper lubrication is a common cause of issues in worm screw systems. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear. On the other hand, over-lubrication can cause excessive drag and fluid churn, leading to inefficient power transmission. It is important to follow the manufacturer’s recommendations for lubrication intervals, types of lubricants, and proper lubrication techniques to ensure optimal performance and longevity of the worm screw system.

- Backlash and Inaccuracy: Backlash refers to the play or clearance between the threads of the worm screw and the teeth of the worm wheel. Excessive backlash can result in reduced accuracy, loss of motion control, and diminished overall system performance. Backlash can be caused by factors such as wear, misalignment, or improper assembly. Regular inspection and adjustment of backlash are necessary to maintain the desired precision and minimize the effects of backlash-related issues.

- Misalignment: Misalignment between the worm screw and the worm wheel can result in increased friction, wear, and inefficiencies. Misalignment can occur due to factors such as improper installation, component deformation, or external forces. It is essential to ensure proper alignment during installation and periodically check for misalignment during routine maintenance. Adjustments should be made as necessary to maintain optimal performance and prevent premature failure.

- Overloading: Subjecting the worm screw gear system to excessive loads beyond its design limits can lead to failure. Overloading can result in accelerated wear, tooth breakage, or component deformation. It is important to operate the system within the specified load limits and consider factors such as shock loads, dynamic loads, and variations in operating conditions. If higher loads are required, it may be necessary to select a worm screw system with a higher load capacity or redesign the system accordingly.

- Corrosion and Contamination: Corrosion and contamination can negatively impact the performance and lifespan of worm screw systems. Exposure to moisture, chemicals, or abrasive particles can lead to corrosion, rusting, or damage to the surfaces of the worm screw and worm wheel. Contamination can interfere with smooth operation and cause accelerated wear. Proper environmental protection, regular cleaning, and appropriate sealing measures can help mitigate the effects of corrosion and contamination.

- Insufficient Stiffness: Worm screws rely on proper support and stiffness to maintain accurate positioning and prevent deflection. Inadequate stiffness in the supporting structure or mounting arrangement can result in excessive deflection, misalignment, and decreased performance. It is crucial to ensure that the worm screw system is properly supported and mounted to maintain the required rigidity and stiffness for optimal operation.

It’s important to note that the specific issues or failures associated with worm screws can vary depending on factors such as the application, operating conditions, maintenance practices, and the quality of the components. Regular inspection, proper lubrication, alignment checks, load monitoring, and adherence to manufacturer guidelines are essential for minimizing the occurrence of these issues and ensuring the reliable and efficient operation of worm screw systems.

Can worm screws be customized for specific engineering needs?

Yes, worm screws can be customized to meet specific engineering needs and application requirements. Customization allows for tailoring the design, dimensions, materials, and other parameters of the worm screw to optimize its performance and functionality. Here are some aspects of worm screws that can be customized:

- Thread Geometry: The thread geometry of a worm screw can be customized to suit specific requirements. This includes the shape, profile, lead angle, and thread form. Custom thread geometries can be designed to optimize load distribution, minimize friction, reduce backlash, improve efficiency, or achieve specific performance characteristics.

- Pitch and Lead: The pitch and lead of a worm screw can be tailored to meet the desired gear ratio, output speed, load capacity, and other performance criteria. Customizing the pitch and lead allows for precise control over the speed reduction or multiplication capabilities of the worm gear system.

- Materials: Worm screws can be customized to be made from different materials based on the specific application requirements. Common materials include steel, stainless steel, bronze, and various alloys. The choice of material depends on factors such as load capacity, durability, corrosion resistance, temperature tolerance, and other environmental considerations.

- Diameter and Length: The diameter and length of a worm screw can be customized to suit the mechanical constraints and dimensional requirements of the application. Custom sizing ensures proper fit, alignment, and integration within the overall system design.

- Coatings and Surface Treatments: Custom coatings or surface treatments can be applied to worm screws to enhance their performance and durability. These can include treatments such as hardening, heat treatment, plating, or specialized coatings to improve wear resistance, reduce friction, or provide corrosion protection.

- Special Features: Worm screws can be customized to incorporate special features or modifications based on specific engineering needs. This may include the addition of keyways, flanges, shaft extensions, or other components to facilitate integration with other system elements or to accommodate unique mechanical requirements.

Customization of worm screws requires collaboration between engineers, designers, and manufacturers with expertise in worm gear systems. It is important to define the specific engineering needs, performance requirements, and operational conditions to ensure that the customized worm screw meets the desired objectives effectively.

What are the typical applications of worm screws in machinery?

Worm screws, also known as worm gears or worm gear screws, have a wide range of applications in machinery where motion transmission and torque multiplication are required. Their unique characteristics make them suitable for various industries and applications. Here are some typical applications of worm screws in machinery:

- Conveyor Systems: Worm screws are commonly used in conveyor systems to control the movement of materials. They provide precise speed reduction and torque multiplication, allowing for efficient transportation of goods in industries such as manufacturing, packaging, and logistics.

- Lifting Mechanisms: Worm screws are extensively used in lifting mechanisms, such as screw jacks or worm gear lifts. They provide reliable and controlled vertical motion for lifting heavy loads in applications like automotive service garages, construction sites, and material handling equipment.

- Winches and Hoists: Worm screws are employed in winches and hoists to provide high torque and controlled lifting or pulling operations. They are commonly used in applications such as cranes, marine equipment, elevators, and stage rigging.

- Rotary Actuators: Worm screws are utilized in rotary actuators to convert the input rotary motion into a controlled rotary output motion. This makes them suitable for applications like valve actuators, positioning systems, and robotic joints.

- Automotive Applications: Worm screws find use in automotive applications, particularly in steering systems. They are employed in steering gearboxes to convert the rotary motion from the steering wheel into the lateral motion required for steering the vehicle.

- Machine Tools: Worm screws are used in machine tools, such as milling machines, lathes, and drill presses, to control various linear and rotary movements. They provide precise positioning and motion control for cutting, shaping, and drilling operations.

- Printing and Packaging Machinery: Worm screws are employed in printing and packaging machinery to control the movement of printing heads, cutting blades, and packaging components. They ensure accurate and synchronized motion for high-quality printing and packaging processes.

- Robotics: Worm screws are utilized in robotics for precise and controlled motion in robotic arms, grippers, and other robotic mechanisms. They enable accurate positioning and smooth motion control in industrial automation and robotic applications.

These are just a few examples of the typical applications of worm screws in machinery. Their ability to provide high gear reduction ratios, precise motion control, and self-locking characteristics make them suitable for a wide range of industries, including manufacturing, construction, automotive, robotics, and many others where efficient power transmission and controlled motion are essential.

editor by CX 2024-02-27

China Good quality Auto Parts Machining Worm Shaft with Best Sales

Product Description

Tapping Screws: Diameter: 2.2 mm. To 6.3 mm.

Length: 4 mm. To 100 mm.

Self-drilling Screws: Diameter: 2.9 mm. To 6.3 mm.

Length: 9 mm. To 100 mm.

Metric Screws: Diameter: M. 2 to M. 8

Length: 3 mm. To 100 mm.

Metric Bolts: Diameter: M. 4 to M. 8

Length: 10 mm. To 100 mm

| MATERIAL | Steel, stainless steel, aluminum, copper, brass, plastic etc metal. |

| Tolerance | ±0.01mm |

| Extent | 0.5mm~1571mm |

| CNC turning work range | φ0.5mm~φ300mm × 650mm |

| CNC milling work range | 510mm × 800mm × 400mm |

| SURFACE TREATMENT | Polishing,chrome,zinc,nickel plating,anodize,power coating, aluminum oxide, brushing. |

| APPLICATION | Auto,motorcycle,bicycle,machine,electronic,furniture,buildings and other industrial uses. |

| COMPETIVE ADVANTAGE | 1.Small order acceptable. |

| 2.Very tight tolerance. | |

| 3.Advanced equipment, excellent R&D teams. | |

| 4.Strict quality control system. | |

| 5.Professional technics and rich experience. | |

| 6.Packaging details as clients required. | |

| INFORMATION TO INQUIRY | 1.Type of material and hardness needed. |

| 2.Quantity of the product. | |

| 3.Part application. | |

| 4.The tolerances of the product. | |

| 5.Drawings, samples or pictures with details. | |

| 6.Target price if you have one. |

Types of Screw Shafts

Screw shafts come in various types and sizes. These types include fully threaded, Lead, and Acme screws. Let’s explore these types in more detail. What type of screw shaft do you need? Which 1 is the best choice for your project? Here are some tips to choose the right screw:

Machined screw shaft

The screw shaft is a basic piece of machinery, but it can be further customized depending on the needs of the customer. Its features include high-precision threads and ridges. Machined screw shafts are generally manufactured using high-precision CNC machines or lathes. The types of screw shafts available vary in shape, size, and material. Different materials are suitable for different applications. This article will provide you with some examples of different types of screw shafts.

Ball screws are used for a variety of applications, including mounting machines, liquid crystal devices, measuring devices, and food and medical equipment. Various shapes are available, including miniature ball screws and nut brackets. They are also available without keyway. These components form a high-accuracy feed mechanism. Machined screw shafts are also available with various types of threaded ends for ease of assembly. The screw shaft is an integral part of linear motion systems.

When you need a machined screw shaft, you need to know the size of the threads. For smaller machine screws, you will need a mating part. For smaller screw sizes, the numbers will be denominated as industry Numeric Sizes. These denominations are not metric, but rather in mm, and they may not have a threads-per-inch designation. Similarly, larger machine screws will usually have threads that have a higher pitch than those with a lower pitch.

Another important feature of machine screws is that they have a thread on the entire shaft, unlike their normal counterparts. These machine screws have finer threads and are intended to be screwed into existing tapped holes using a nut. This means that these screws are generally stronger than other fasteners. They are usually used to hold together electronic components, industrial equipment, and engines. In addition to this, machine screws are usually made of a variety of materials.

Acme screw

An Acme screw is the most common type of threaded shaft available. It is available in a variety of materials including stainless steel and carbon steel. In many applications, it is used for large plates in crushing processes. ACME screws are self-locking and are ideal for applications requiring high clamping force and low friction. They also feature a variety of standard thread forms, including knurling and rolled worms.

Acme screws are available in a wide range of sizes, from 1/8″ to 6″. The diameter is measured from the outside of the screw to the bottom of the thread. The pitch is equal to the lead in a single start screw. The lead is equal to the pitch plus the number of starts. A screw of either type has a standard pitch and a lead. Acme screws are manufactured to be accurate and durable. They are also widely available in a wide range of materials and can be customized to fit your needs.

Another type of Acme screw is the ball screw. These have no back drive and are widely used in many applications. Aside from being lightweight, they are also able to move at faster speeds. A ball screw is similar to an Acme screw, but has a different shape. A ball screw is usually longer than an Acme screw. The ball screw is used for applications that require high linear speeds. An Acme screw is a common choice for many industries.

There are many factors that affect the speed and resolution of linear motion systems. For example, the nut position and the distance the screw travels can all affect the resolution. The total length of travel, the speed, and the duty cycle are all important. The lead size will affect the maximum linear speed and force output. If the screw is long, the greater the lead size, the higher the resolution. If the lead length is short, this may not be the most efficient option.

Lead screw

A lead screw is a threaded mechanical device. A lead screw consists of a cylindrical shaft, which includes a shallow thread portion and a tightly wound spring wire. This spring wire forms smooth, hard-spaced thread convolutions and provides wear-resistant engagement with the nut member. The wire’s leading and trailing ends are anchored to the shaft by means appropriate to the shaft’s composition. The screw is preferably made of stainless steel.

When selecting a lead screw, 1 should first determine its critical speed. The critical speed is the maximum rotations per minute based on the natural frequency of the screw. Excessive backlash will damage the lead screw. The maximum number of revolutions per minute depends on the screw’s minor diameter, length, assembly alignment, and end fixity. Ideally, the critical speed is 80% of its evaluated critical speed. A critical speed is not exceeded because excessive backlash would damage the lead screw and may be detrimental to the screw’s performance.

The PV curve defines the safe operating limits of a lead screw. This relationship describes the inverse relationship between contact surface pressure and sliding velocity. As the PV value increases, a lower rotation speed is required for heavier axial loads. Moreover, PV is affected by material and lubrication conditions. Besides, end fixity, which refers to the way the lead screw is supported, also affects its critical speed. Fixed-fixed and free end fixity are both possible.

Lead screws are widely used in industries and everyday appliances. In fact, they are used in robotics, lifting equipment, and industrial machinery. High-precision lead screws are widely used in the fields of engraving, fluid handling, data storage, and rapid prototyping. Moreover, they are also used in 3D printing and rapid prototyping. Lastly, lead screws are used in a wide range of applications, from measuring to assembly.

Fully threaded screw

A fully threaded screw shaft can be found in many applications. Threading is an important feature of screw systems and components. Screws with threaded shafts are often used to fix pieces of machinery together. Having fully threaded screw shafts ensures that screws can be installed without removing the nut or shaft. There are 2 major types of screw threads: coarse and fine. When it comes to coarse threads, UTS is the most common type, followed by BSP.

In the 1840s, a British engineer named Joseph Whitworth created a design that was widely used for screw threads. This design later became the British Standard Whitworth. This standard was used for screw threads in the United States during the 1840s and 1860s. But as screw threads evolved and international standards were established, this system remained largely unaltered. A new design proposed in 1864 by William Sellers improved upon Whitworth’s screw threads and simplified the pitch and surface finish.

Another reason for using fully threaded screws is their ability to reduce heat. When screw shafts are partially threaded, the bone grows up to the screw shaft and causes the cavity to be too narrow to remove it. Consequently, the screw is not capable of backing out. Therefore, fully threaded screws are the preferred choice for inter-fragmentary compression in children’s fractures. However, surgeons should know the potential complication when removing metalwork.

The full thread depth of a fully threaded screw is the distance at which a male thread can freely thread into the shaft. This dimension is typically 1 millimeter shy of the total depth of the drilled hole. This provides space for tap lead and chips. The full-thread depth also makes fully threaded screws ideal for axially-loaded connections. It is also suitable for retrofitting applications. For example, fully threaded screws are commonly used to connect 2 elements.

Ball screw

The basic static load rating of a ball screw is determined by the product of the maximum axial static load and the safety factor “s0”. This factor is determined by past experience in similar applications and should be selected according to the design requirements of the application. The basic static load rating is a good guideline for selecting a ball screw. There are several advantages to using a ball screw for a particular application. The following are some of the most common factors to consider when selecting a ball screw.

The critical speed limit of a ball screw is dependent on several factors. First of all, the critical speed depends on the mass, length and diameter of the shaft. Second, the deflection of the shaft and the type of end bearings determine the critical speed. Finally, the unsupported length is determined by the distance between the ball nut and end screw, which is also the distance between bearings. Generally, a ball screw with a diameter greater than 1.2 mm has a critical speed limit of 200 rpm.

The first step in manufacturing a high-quality ball screw is the choice of the right steel. While the steel used for manufacturing a ball screw has many advantages, its inherent quality is often compromised by microscopic inclusions. These microscopic inclusions may eventually lead to crack propagation, surface fatigue, and other problems. Fortunately, the technology used in steel production has advanced, making it possible to reduce the inclusion size to a minimum. However, higher-quality steels can be expensive. The best material for a ball screw is vacuum-degassed pure alloy steel.

The lead of a ball screw shaft is also an important factor to consider. The lead is the linear distance between the ball and the screw shaft. The lead can increase the amount of space between the balls and the screws. In turn, the lead increases the speed of a screw. If the lead of a ball screw is increased, it may increase its accuracy. If not, the lead of a ball screw can be improved through preloading, lubrication, and better mounting accuracy.

China wholesaler CNC Machining Auto Spare Parts Car Accessories Worm Shaft Gears for Machine Part with Best Sales

Product Description

1, production technology: forging machining stamping sand casting die casting investment casting

2,Material: grey iron stainless steel aluminum

3, single process, high precision, little surface roughness,

4, customized, we produce the parts according to drawings or samples,

5, we will inspect the parts strictly and provide material and inspection report.

Packing and Shipping

Grey Iron Housing with Sand Casting Process

1. Standard: crate

2. Delivery: As per contract delivery on time

3. Shipping: As per client request.

Our advantages

1.We can control the products to meet your strict requirement.

2. Different kinds of finish available, like anodized, power coating, painting, polishing, electrophoresis, plating. Etc.

3. Different dimensions according to the requirements

4. Can provide various sizes and packing according to specific requirements

5. We offer the engineer consultation to your design for production improvement and cost saving

Our Service:

1.Your inquiry related to our products or prices will be replied in 24 hours.

2.Individual formula according to customers’ special drawing requests.

3.Manufacturer with large capacity, ensures the fast production cycle after

confirming the order.

4.Protection of sales area and private information for all of our customers.

Screw Sizes and Their Uses

Screws have different sizes and features. This article will discuss screw sizes and their uses. There are 2 main types: right-handed and left-handed screw shafts. Each screw features a point that drills into the object. Flat tipped screws, on the other hand, need a pre-drilled hole. These screw sizes are determined by the major and minor diameters. To determine which size of screw you need, measure the diameter of the hole and the screw bolt’s thread depth.

The major diameter of a screw shaft

The major diameter of a screw shaft is the distance from the outer edge of the thread on 1 side to the tip of the other. The minor diameter is the inner smooth part of the screw shaft. The major diameter of a screw is typically between 2 and 16 inches. A screw with a pointy tip has a smaller major diameter than 1 without. In addition, a screw with a larger major diameter will have a wider head and drive.

The thread of a screw is usually characterized by its pitch and angle of engagement. The pitch is the angle formed by the helix of a thread, while the crest forms the surface of the thread corresponding to the major diameter of the screw. The pitch angle is the angle between the gear axis and the pitch surface. Screws without self-locking threads have multiple starts, or helical threads.

The pitch is a crucial component of a screw’s threading system. Pitch is the distance from a given thread point to the corresponding point of the next thread on the same shaft. The pitch line is 1 element of pitch diameter. The pitch line, or lead, is a crucial dimension for the thread of a screw, as it controls the amount of thread that will advance during a single turn.

The pitch diameter of a screw shaft

When choosing the appropriate screw, it is important to know its pitch diameter and pitch line. The pitch line designates the distance between adjacent thread sides. The pitch diameter is also known as the mean area of the screw shaft. Both of these dimensions are important when choosing the correct screw. A screw with a pitch of 1/8 will have a mechanical advantage of 6.3. For more information, consult an application engineer at Roton.

The pitch diameter of a screw shaft is measured as the distance between the crest and the root of the thread. Threads that are too long or too short will not fit together in an assembly. To measure pitch, use a measuring tool with a metric scale. If the pitch is too small, it will cause the screw to loosen or get stuck. Increasing the pitch will prevent this problem. As a result, screw diameter is critical.

The pitch diameter of a screw shaft is measured from the crest of 1 thread to the corresponding point on the next thread. Measurement is made from 1 thread to another, which is then measured using the pitch. Alternatively, the pitch diameter can be approximated by averaging the major and minor diameters. In most cases, the pitch diameter of a screw shaft is equal to the difference between the two.

The thread depth of a screw shaft

Often referred to as the major diameter, the thread depth is the outermost diameter of the screw. To measure the thread depth of a screw, use a steel rule, micrometer, or caliper. In general, the first number in the thread designation indicates the major diameter of the thread. If a section of the screw is worn, the thread depth will be smaller, and vice versa. Therefore, it is good practice to measure the section of the screw that receives the least amount of use.

In screw manufacturing, the thread depth is measured from the crest of the screw to the root. The pitch diameter is halfway between the major and minor diameters. The lead diameter represents the amount of linear distance traveled in 1 revolution. As the lead increases, the load capacity decreases. This measurement is primarily used in the construction of screws. However, it should not be used for precision machines. The thread depth of a screw shaft is essential for achieving accurate screw installation.

To measure the thread depth of a screw shaft, the manufacturer must first determine how much material the thread is exposed to. If the thread is exposed to side loads, it can cause the nut to wedge. Because the nut will be side loaded, its thread flanks will contact the nut. The less clearance between the nut and the screw, the lower the clearance between the nut and the screw. However, if the thread is centralized, there is no risk of the nut wedgeing.

The lead of a screw shaft

Pitch and lead are 2 measurements of a screw’s linear distance per turn. They’re often used interchangeably, but their definitions are not the same. The difference between them lies in the axial distance between adjacent threads. For single-start screws, the pitch is equal to the lead, while the lead of a multi-start screw is greater than the pitch. This difference is often referred to as backlash.

There are 2 ways to calculate the pitch and lead of a screw. For single-start screws, the lead and pitch are equal. Multiple-start screws, on the other hand, have multiple starts. The pitch of a multiple-start screw is the same as its lead, but with 2 or more threads running the length of the screw shaft. A square-thread screw is a better choice in applications requiring high load-bearing capacity and minimal friction losses.

The PV curve defines the safe operating limits of lead screw assemblies. It describes the inverse relationship between contact surface pressure and sliding velocity. As the load increases, the lead screw assembly must slow down in order to prevent irreversible damage from frictional heat. Furthermore, a lead screw assembly with a polymer nut must reduce rpm as the load increases. The more speed, the lower the load capacity. But, the PV factor must be below the maximum allowed value of the material used to make the screw shaft.

The thread angle of a screw shaft

The angle between the axes of a thread and the helix of a thread is called the thread angle. A unified thread has a 60-degree angle in all directions. Screws can have either a tapped hole or a captive screw. The screw pitch is measured in millimeters (mm) and is usually equal to the screw major diameter. In most cases, the thread angle will be equal to 60-degrees.

Screws with different angles have various degrees of thread. Originally, this was a problem because of the inconsistency in the threading. However, Sellers’s thread was easier to manufacture and was soon adopted as a standard throughout the United States. The United States government began to adopt this thread standard in the mid-1800s, and several influential corporations in the railroad industry endorsed it. The resulting standard is called the United States Standard thread, and it became part of the ASA’s Vol. 1 publication.

There are 2 types of screw threads: coarse and fine. The latter is easier to tighten and achieves tension at lower torques. On the other hand, the coarse thread is deeper than the fine one, making it easier to apply torque to the screw. The thread angle of a screw shaft will vary from bolt to bolt, but they will both fit in the same screw. This makes it easier to select the correct screw.

The tapped hole (or nut) into which the screw fits

A screw can be re-threaded without having to replace it altogether. The process is different than that of a standard bolt, because it requires threading and tapping. The size of a screw is typically specified by its major and minor diameters, which is the inside distance between threads. The thread pitch, which is the distance between each thread, is also specified. Thread pitch is often expressed in threads per inch.

Screws and bolts have different thread pitches. A coarse thread has fewer threads per inch and a longer distance between threads. It is therefore larger in diameter and longer than the material it is screwed into. A coarse thread is often designated with an “A” or “B” letter. The latter is generally used in smaller-scale metalworking applications. The class of threading is called a “threaded hole” and is designated by a letter.

A tapped hole is often a complication. There is a wide range of variations between the sizes of threaded holes and nut threads, so the tapped hole is a critical dimension in many applications. However, even if you choose a threaded screw that meets the requisite tolerance, there may be a mismatch in the thread pitch. This can prevent the screw from freely rotating.

China Hot selling Worm Gear Shaft Gear for Air Compressing Spare Parts near me supplier

Product Description

China professional worm shaft and worm wheel supplier

1. Name: Worm shaft and worm wheel

2. OEM service is welcome

3. Sample is first

4. All the products are tested

5. Prompt delivery

High precision worm shaft:

Usage: Connecting or transmission for machines

Tolerence: Strictly as the designs

Roughness: Min Ra0.01

Hardness: HRC/HV

Material: 20CrMoTi, 45# steel, 42CrMo, GCr15( according with your require)

Diameter: 15mm~120mm

Length: Within 4 meters

Surface treatment: Zinc plating, chrome plating and so on, be according to your requirements.

Processing: By machining

| Material available | Carbon steel, Stainless steel, spring steel, Bronze, brass, copper alloy, aluminum alloy, tinplate, nickel silver, plastic |

| Surface treatment | Polishing\Spray Coating\Deburring\Electroplating\Oxygenation\Baking Paint\Grind\Oil CZPT , etc. |

| Manufacturing Methods |

Investment Casting, Die Casting, Sand Casting, Stamping, CNC Machining, Forging, |

| Specification | OEM & Custom According to Drawing or Samples |

| Package | Standard Export Carton/According to customer’ s requirement |

Screw Sizes and Their Uses

Screws have different sizes and features. This article will discuss screw sizes and their uses. There are 2 main types: right-handed and left-handed screw shafts. Each screw features a point that drills into the object. Flat tipped screws, on the other hand, need a pre-drilled hole. These screw sizes are determined by the major and minor diameters. To determine which size of screw you need, measure the diameter of the hole and the screw bolt’s thread depth.

The major diameter of a screw shaft

The major diameter of a screw shaft is the distance from the outer edge of the thread on 1 side to the tip of the other. The minor diameter is the inner smooth part of the screw shaft. The major diameter of a screw is typically between 2 and 16 inches. A screw with a pointy tip has a smaller major diameter than 1 without. In addition, a screw with a larger major diameter will have a wider head and drive.

The thread of a screw is usually characterized by its pitch and angle of engagement. The pitch is the angle formed by the helix of a thread, while the crest forms the surface of the thread corresponding to the major diameter of the screw. The pitch angle is the angle between the gear axis and the pitch surface. Screws without self-locking threads have multiple starts, or helical threads.

The pitch is a crucial component of a screw’s threading system. Pitch is the distance from a given thread point to the corresponding point of the next thread on the same shaft. The pitch line is 1 element of pitch diameter. The pitch line, or lead, is a crucial dimension for the thread of a screw, as it controls the amount of thread that will advance during a single turn.

The pitch diameter of a screw shaft

When choosing the appropriate screw, it is important to know its pitch diameter and pitch line. The pitch line designates the distance between adjacent thread sides. The pitch diameter is also known as the mean area of the screw shaft. Both of these dimensions are important when choosing the correct screw. A screw with a pitch of 1/8 will have a mechanical advantage of 6.3. For more information, consult an application engineer at Roton.

The pitch diameter of a screw shaft is measured as the distance between the crest and the root of the thread. Threads that are too long or too short will not fit together in an assembly. To measure pitch, use a measuring tool with a metric scale. If the pitch is too small, it will cause the screw to loosen or get stuck. Increasing the pitch will prevent this problem. As a result, screw diameter is critical.

The pitch diameter of a screw shaft is measured from the crest of 1 thread to the corresponding point on the next thread. Measurement is made from 1 thread to another, which is then measured using the pitch. Alternatively, the pitch diameter can be approximated by averaging the major and minor diameters. In most cases, the pitch diameter of a screw shaft is equal to the difference between the two.

The thread depth of a screw shaft

Often referred to as the major diameter, the thread depth is the outermost diameter of the screw. To measure the thread depth of a screw, use a steel rule, micrometer, or caliper. In general, the first number in the thread designation indicates the major diameter of the thread. If a section of the screw is worn, the thread depth will be smaller, and vice versa. Therefore, it is good practice to measure the section of the screw that receives the least amount of use.

In screw manufacturing, the thread depth is measured from the crest of the screw to the root. The pitch diameter is halfway between the major and minor diameters. The lead diameter represents the amount of linear distance traveled in 1 revolution. As the lead increases, the load capacity decreases. This measurement is primarily used in the construction of screws. However, it should not be used for precision machines. The thread depth of a screw shaft is essential for achieving accurate screw installation.

To measure the thread depth of a screw shaft, the manufacturer must first determine how much material the thread is exposed to. If the thread is exposed to side loads, it can cause the nut to wedge. Because the nut will be side loaded, its thread flanks will contact the nut. The less clearance between the nut and the screw, the lower the clearance between the nut and the screw. However, if the thread is centralized, there is no risk of the nut wedgeing.

The lead of a screw shaft

Pitch and lead are 2 measurements of a screw’s linear distance per turn. They’re often used interchangeably, but their definitions are not the same. The difference between them lies in the axial distance between adjacent threads. For single-start screws, the pitch is equal to the lead, while the lead of a multi-start screw is greater than the pitch. This difference is often referred to as backlash.

There are 2 ways to calculate the pitch and lead of a screw. For single-start screws, the lead and pitch are equal. Multiple-start screws, on the other hand, have multiple starts. The pitch of a multiple-start screw is the same as its lead, but with 2 or more threads running the length of the screw shaft. A square-thread screw is a better choice in applications requiring high load-bearing capacity and minimal friction losses.

The PV curve defines the safe operating limits of lead screw assemblies. It describes the inverse relationship between contact surface pressure and sliding velocity. As the load increases, the lead screw assembly must slow down in order to prevent irreversible damage from frictional heat. Furthermore, a lead screw assembly with a polymer nut must reduce rpm as the load increases. The more speed, the lower the load capacity. But, the PV factor must be below the maximum allowed value of the material used to make the screw shaft.

The thread angle of a screw shaft

The angle between the axes of a thread and the helix of a thread is called the thread angle. A unified thread has a 60-degree angle in all directions. Screws can have either a tapped hole or a captive screw. The screw pitch is measured in millimeters (mm) and is usually equal to the screw major diameter. In most cases, the thread angle will be equal to 60-degrees.

Screws with different angles have various degrees of thread. Originally, this was a problem because of the inconsistency in the threading. However, Sellers’s thread was easier to manufacture and was soon adopted as a standard throughout the United States. The United States government began to adopt this thread standard in the mid-1800s, and several influential corporations in the railroad industry endorsed it. The resulting standard is called the United States Standard thread, and it became part of the ASA’s Vol. 1 publication.

There are 2 types of screw threads: coarse and fine. The latter is easier to tighten and achieves tension at lower torques. On the other hand, the coarse thread is deeper than the fine one, making it easier to apply torque to the screw. The thread angle of a screw shaft will vary from bolt to bolt, but they will both fit in the same screw. This makes it easier to select the correct screw.

The tapped hole (or nut) into which the screw fits

A screw can be re-threaded without having to replace it altogether. The process is different than that of a standard bolt, because it requires threading and tapping. The size of a screw is typically specified by its major and minor diameters, which is the inside distance between threads. The thread pitch, which is the distance between each thread, is also specified. Thread pitch is often expressed in threads per inch.

Screws and bolts have different thread pitches. A coarse thread has fewer threads per inch and a longer distance between threads. It is therefore larger in diameter and longer than the material it is screwed into. A coarse thread is often designated with an “A” or “B” letter. The latter is generally used in smaller-scale metalworking applications. The class of threading is called a “threaded hole” and is designated by a letter.

A tapped hole is often a complication. There is a wide range of variations between the sizes of threaded holes and nut threads, so the tapped hole is a critical dimension in many applications. However, even if you choose a threaded screw that meets the requisite tolerance, there may be a mismatch in the thread pitch. This can prevent the screw from freely rotating.

China wholesaler Factory supply machinery parts flexible chain coupling drive shaft coupling with low cost near me shop

Relevant Industries: Creating Substance Stores, Machinery Fix Shops, House Use, Retail, Printing Stores, Development functions

Construction: Disc

Flexible or Rigid: Adaptable

Normal or Nonstandard: Nonstandard

Content: Metal, Ratio 5 Precision Spur Planetary Gearbox For Nema34 Servo Motor Robot Arm steel,Aluminum or as needed

Product identify: travel shaft coupling

Surface Therapy: Paint

Packing: Carton Box or as needed

Shade: as picture demonstrate

OEM: Appropriate

MOQ: 1PC

Provider: Manufactured-to-purchase

Kind: Nonstandard

Attribute: Heat Handled

Packaging Specifics: drive shaft couplinginner polybag+carton box

Manufacturing unit offer equipment components flexible chain coupling push shaft coupling with lower expense Product nameFactory source equipment elements flexible chain coupling generate shaft coupling with minimal costMaterialAluminum AlloyServicemake to orderMOQ100PCSOEMYESPackagecarton box / picket scenario Packing&Transport Solitary item: innner bundle: plastic bag outter package: wood scenario Delivery Mini order quantity will get 7-15 functioning days For bulk purchase or some urgent items we can negotiate about the time Business Introduction ZHangZhoug CZPT Machinery Co.,LtdOur firm is a family members-owned enterprise. The person in demand of the company has been engaged in the equipment sector for morethan 20 many years and has prosperous industry knowledge.We are specializing in creating standard sprocket,non-common sprocket,rollerchain and other appropriate products.Have a comprehensive and scientific administration crew and a set of sophisticated creation equipment. Items have been promoting all over the world with great comments and used in several fields.If you offer you us the sample or the drawdesign, Adjustable Pulley Cable, Upgraded Loading Pin Cable Pulley Attachment we can make them for you.We are warmly welcome you to go to our manufacturing unit and cooperate with us!You should really do not hesitate tocontact us for inquiry! Associated Items FAQ Q1: Are you a trading firm or a company?A1: We are a manufacturing unit with specialist workers, designers good quality inspector group. Q2: How about your delivery time?A2: Generally, it will consider thirty times if we have goods in inventory, Wholesale Price tag 6 Pace MLGU Gearbox Transmission Gear 6th Gear 31 Enamel For Fiat Ducato Peugeot Boxer Citroen Relay 9649785718 we can negotiate about the supply time accordingto the quantity or If you are in urgent need to have, . Q3: Can you manufacture personalized products?A3: Sure, we can manufacture the items you want as prolonged as you provide us the sample or layout drawing. This fall: Do you examination you items before delivery?A4: Indeed. We have 100% detection and check ahead of delivery. Q5: What is your conditions of payment?A6: Payment=1000USD, cyclo planetary equipment reducer cvms varitron cyclo drive gear box pace lessen xwd cycloid gearbox reducer thirty% T/T in progress, balance just before shipment. Why Pick Us

Why Examining the Drive Shaft is Essential

If you hear clicking noises whilst driving, your driveshaft may want restore. An knowledgeable mechanic can inform if the sounds is coming from 1 aspect or both sides. This difficulty is usually relevant to the torque converter. Go through on to find out why it’s so essential to have your driveshaft inspected by an automobile mechanic. Below are some signs to look for. Clicking noises can be induced by numerous various things. You need to very first verify if the sounds is coming from the entrance or the rear of the automobile.

hollow generate shaft

Hollow driveshafts have many benefits. They are mild and minimize the total weight of the car. The premier manufacturer of these elements in the entire world is CZPT. They also offer you light-weight solutions for various programs, these kinds of as high-functionality axles. CZPT driveshafts are manufactured employing condition-of-the-art technology. They offer you exceptional good quality at aggressive prices.

The internal diameter of the hollow shaft reduces the magnitude of the inner forces, therefore lowering the volume of torque transmitted. In contrast to reliable shafts, hollow shafts are acquiring more powerful. The content inside of the hollow shaft is a bit lighter, which additional decreases its weight and all round torque. Nevertheless, this also increases its drag at high speeds. This means that in a lot of apps hollow driveshafts are not as effective as solid driveshafts.

A conventional hollow push shaft is composed of a initial rod fourteen and a second rod 14 on both sides. The 1st rod is connected with the next rod, and the 2nd rod extends in the rotation route. The two rods are then friction welded to the central location of the hollow shaft. The frictional heat created for the duration of the relative rotation aids to link the two components. Hollow generate shafts can be used in internal combustion engines and environmentally-friendly autos.

The principal benefit of a hollow driveshaft is fat reduction. The splines of the hollow drive shaft can be developed to be smaller than the exterior diameter of the hollow shaft, which can significantly minimize fat. Hollow shafts are also much less most likely to jam when compared to strong shafts. Hollow driveshafts are envisioned to ultimately occupy the entire world market place for automotive driveshafts. Its positive aspects contain gasoline effectiveness and increased versatility when compared to solid prop shafts.

Cardan shaft

Cardan shafts are a popular decision in industrial equipment. They are employed to transmit energy from 1 equipment to an additional and are obtainable in a range of sizes and designs. They are offered in a selection of supplies, including metal, copper, and aluminum. If you prepare to install one of these shafts, it is critical to know the distinct varieties of Cardan shafts available. To find the ideal alternative, browse the catalog.

Telescopic or “Cardan” prop shafts, also recognized as U-joints, are best for productive torque transfer amongst the travel and output technique. They are effective, light-weight, and energy-efficient. They employ sophisticated methods, which includes finite factor modeling (FEM), to guarantee maximum performance, fat, and performance. Moreover, the Cardan shaft has an adjustable duration for easy repositioning.

Yet another common choice for driveshafts is the Cardan shaft, also recognized as a driveshaft. The objective of the driveshaft is to transfer torque from the motor to the wheels. They are typically employed in higher-overall performance car engines. Some types are created of brass, iron, or metal and have exclusive area patterns. Cardan shafts are obtainable in inclined and parallel configurations.

One Cardan shafts are a widespread alternative for standard Cardan shafts, but if you are searching for twin Cardan shafts for your automobile, you will want to choose the 1310 series. This sort is excellent for lifted jeeps and needs a CV-compatible transfer scenario. Some even need axle spacers. The twin Cardan shafts are also designed for lifts, which signifies it’s a excellent choice for increasing and reducing jeeps.

common joint

Cardan joints are a good option for drive shafts when functioning at a continual velocity. Their style makes it possible for a consistent angular velocity ratio between the enter and output shafts. Dependent on the software, the recommended speed restrict might fluctuate dependent on the operating angle, transmission power, and application. These tips should be based on force. The greatest permissible velocity of the drive shaft is decided by determining the angular acceleration.

Due to the fact gimbal joints never call for grease, they can very last a lengthy time but ultimately fail. If they are badly lubricated or dry, they can result in steel-to-metal get in touch with. The exact same is real for U-joints that do not have oil filling ability. While they have a prolonged lifespan, it can be difficult to place warning indications that could reveal impending joint failure. To avoid this, examine the drive shaft routinely.

U-joints ought to not exceed seventy p.c of their lateral essential velocity. However, if this pace is exceeded, the portion will knowledge unacceptable vibration, reducing its useful existence. To figure out the greatest U-joint for your application, make sure you get in touch with your universal joint supplier. Generally, lower speeds do not require balancing. In these cases, you need to think about using a more substantial pitch diameter to minimize axial drive.

To lessen the angular velocity and torque of the output shaft, the two joints have to be in phase. As a result, the output shaft angular displacement does not completely follow the input shaft. Alternatively, it will direct or lag. Figure 3 illustrates the angular velocity variation and peak displacement direct of the gimbal. The ratios are shown under. The appropriate torque for this software is 1360 in-Ibs.

Refurbished push shaft

Refurbished driveshafts are a very good decision for a variety of reasons. They are more affordable than brand new choices and typically just as trustworthy. Driveshafts are crucial to the perform of any car, truck, or bus. These parts are manufactured of hollow metal tubes. While this assists lessen weight and cost, it is susceptible to exterior influences. If this happens, it may possibly crack or bend. If the shaft suffers this variety of damage, it can cause severe damage to the transmission.

A car’s driveshaft is a critical element that transmits torque from the motor to the wheels. A1 Drive Shaft is a international provider of automotive driveshafts and connected parts. Their manufacturing facility has the ability to refurbish and restore practically any make or design of driveshafts. Refurbished driveshafts are available for each make and product of vehicle. They can be identified on the market for a range of cars, such as passenger automobiles, vehicles, vans, and SUVs.

Abnormal noises point out that your driveshaft wants to be changed. Worn U-joints and bushings can lead to extreme vibration. These elements cause use on other parts of the drivetrain. If you notice any of these signs and symptoms, please take your automobile to the AAMCO Bay Spot Middle for a comprehensive inspection. If you suspect injury to the driveshaft, don’t wait around another moment – it can be very unsafe.

The cost of changing the push shaft

The value of changing a driveshaft varies, but on regular, this restore costs among $two hundred and $1,five hundred. While this value could vary by vehicle, the expense of areas and labor is normally equivalent. If you do the restore oneself, you must know how a lot the components and labor will value prior to you begin operate. Some elements can be a lot more high-priced than other people, so it is a great notion to examine the cost of several locations ahead of determining where to go.

If you discover any of these symptoms, you must look for a restore store right away. If you are nonetheless not certain if the driveshaft is damaged, do not travel the vehicle any distance until it is repaired. Indicators to look for consist of deficiency of electrical power, trouble transferring the auto, squeaking, clanking, or vibrating when the vehicle is moving.

Areas employed in travel shafts contain middle support bearings, slip joints, and U-joints. The value of the driveshaft differs by vehicle and might vary by design of the very same yr. Also, diverse kinds of driveshafts need diverse mend strategies and are considerably a lot more pricey. Total, however, a driveshaft replacement charges amongst $three hundred and $1,300. The method could consider about an hour, relying on the motor vehicle model.

Numerous aspects can guide to the need to have to exchange the push shaft, including bearing corrosion, destroyed seals, or other elements. In some cases, the U-joint indicates that the generate shaft wants to be changed. Even if the bearings and u-joints are in excellent issue, they will ultimately crack and require the substitute of the drive shaft. However, these areas are not inexpensive, and if a damaged driveshaft is a symptom of a larger dilemma, you ought to consider the time to substitute the shaft.

China Professional EEP Auto Parts Car Cv Axle Drive Shaft For CZPT Honda Nissan Mazda Hyundai CZPT Kia CZPT VW Mazda BMW Benz with Best Sales

Model: CR-V, Jazz, Stepwgn, Civic, Fit, City Saloon (GM4, GM5, GM6, GM9), STEPWGN (LA-RF_, UA-RF_), Accord, Legend, Atos, Sonata, Accent, Santa Fe, GRANDEUR, I20, IX20, 626, 323, 3, MPV, 6, WINGROAD / Ad Wagon (_Y12), SUNNY, BLUEBIRD, NAVARA System/Chassis (D23), SENTRA, PATROL, TEANA II (J32), Choose UP (D22), PRIMERA Hatchback (P12), MAXIMA VII (A35), MURANO III (Z52_), X-Trail (T32_), PATHFINDER IV (R52), Caravan, ELGRAND (E52), OEM Galvanized Gold Sliver Colour Pulley Gate Sliding Door Wheel With Bracket Bearing BLUEBIRD SYLPHY II (G11), SKYLINE, PRIMASTAR Bus (X83), ALTIMA (L33), CHERRY, VERSA II, Legacy, STELLA, IMPREZA, Forester, AVENSIS Saloon (_T27_), MARK II Saloon (_X11_), CROWN, PREVIA III (_R2_, _R5_), PASSO (_NGC3_, _KGC3_), COROLLA Estate (_E16_), LAND CRUISER PRADO (_J12_), HIGHLANDER / KLUGER (_U5_), LAND CRUISER PRADO (_J15_), AVALON Saloon (_X3_), HIACE IV Bus (_H1_, _H2_), VISTA Saloon (_V5_), Prius, RAV4, CARINA Saloon (_T21_), YARIS, HILUX VII Pickup (_N1_, _N2_, _N3_), 4 RUNNER (_N28_), COROLLA Estate (_E14_), STARLET, PICNIC (_XM1_)

Calendar year: 2014-2015, 2011-2012, 2012-2016, 2013-2016, 2015-2016, CZPT HTll2L Little dimensions plastic pe ldpe pvc kids toy make extrusion blow molding equipment 2014-2016, 2009-2012, 2008-, 2008-2016, 2015-2016, 2015-2016, 2004-2016, 2011-2016, 2011-2016, 2015-2016, 2016-2016, 2571-2016, 2571-2016, 2013-2016, 1995, 2001-2002, 2002-2006, 2006-2016, 1991-1997, 1984-1986, 2002-2016, 2008-2015, 2012-2016, 2011-2016, 2006-2007, 2011-2016, 2571-2016, 2571-2016, 2014-, 2012-2016, 2571-2016, 1996-1999, 2009-2016, 2015-2016, 2014-2016, 2012-2016, 2005-2012, 2006-, 2009-, 2013-, China offer new Advance marine gearbox 16a for maritime motor 2012-, 2005-, 2008-, 1996-2001, 2002-2004, 1995-, 2009-, 1996-2001, 1998-2003, 2571-, 2004-, 2002-2009, 2008-, 2571-, 2012-, 1997-, 2014-, 2005-, 2000-2005, 2012-, 2013-, 2002-, 2012-, 2001-, 2011-, 2015-, 2005-, 2008-2013

OE NO.: OE Num or Automobile Chassis amount

Automobile Fitment: Mazda, Nissan, HONDA, Subaru, Hyundai, Toyota

Reference NO.: 150 1877-SX, 571KB4A47

Dimensions: OEM STHangZhouRD

Substance: Steel

Design Number: OE Num or Automobile Chassis number

Guarantee: 2 Years

Vehicle Make: for Japanese cars

Packing Specifics: EEP Manufacturer Packing or as Customer’s Requirements

Sample: Charge samples offered, please Get in touch with us

Certification: ISO9001, TS16949, SGS

Shipping and delivery time: 1-7 days for inventory objects, 25 days for creation items

Inventory QTY: 200 Pcs

Payment: L/C, T/T, Western Union, U604ZZ 604UU 4134mm U Groove Pulley Xihu (West Lake) Dis. Monitor Roller Bearing For 3D Printer Extruder Timing Belt Elements Other (Cash)

MOQ: 4 PCS

Certification: ISO 9001/TS16949

Packaging Information: EEP Model nylon bag & box Packing or as Customer’s Needs

Port: HangZhou

Warm Suggestion:pls get in touch with us to affirm your auto model and OEM amount. Merchandise NameDrive shaftMOQ10BrandEEPWarranty1 yearDelivery Time1-7 days If you have any issue pls really feel cost-free make contact with us , Thank you for your assistance.

Driveshaft composition and vibrations associated with it

The framework of the generate shaft is crucial to its performance and trustworthiness. Push shafts generally include claw couplings, rag joints and common joints. Other generate shafts have prismatic or splined joints. Discover about the diverse kinds of generate shafts and how they work. If you want to know the vibrations related with them, read through on. But 1st, let’s outline what a driveshaft is.

transmission shaft

As the demand on our cars carries on to enhance, so does the desire on our travel methods. Higher CO2 emission standards and stricter emission specifications improve the anxiety on the push program while bettering convenience and shortening the turning radius. These and other negative consequences can location substantial tension and dress in on factors, which can direct to driveshaft failure and improve motor vehicle security dangers. For that reason, the travel shaft need to be inspected and replaced routinely.

Dependent on your design, you might only need to change one particular driveshaft. Nonetheless, the price to exchange the two driveshafts ranges from $650 to $1850. Additionally, you could incur labor fees ranging from $one hundred forty to $250. The labor price will count on your car product and its drivetrain kind. In basic, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft marketplace can be divided into 4 major marketplaces: North America, Europe, Asia Pacific, and Rest of the Globe. North The united states is predicted to dominate the market place, while Europe and Asia Pacific are predicted to grow the speediest. Additionally, the market place is expected to grow at the greatest rate in the long term, pushed by economic expansion in the Asia Pacific location. Furthermore, most of the cars marketed globally are made in these regions.

The most important characteristic of the driveshaft is to transfer the energy of the engine to beneficial operate. Travel shafts are also acknowledged as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or each. Due to the complexity of driveshaft assemblies, they are crucial to motor vehicle safety. In addition to transmitting torque from the engine, they should also compensate for deflection, angular alterations and duration adjustments.

type

Various kinds of generate shafts consist of helical shafts, equipment shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head give a rotationally secure link. At least one particular bearing has a groove extending alongside its circumferential size that allows the pin to go by means of the bearing. There can also be two flanges on each and every finish of the shaft. Relying on the software, the shaft can be mounted in the most convenient place to perform.

Propeller shafts are typically manufactured of substantial-high quality metal with substantial distinct power and modulus. Nonetheless, they can also be produced from superior composite components such as carbon fiber, Kevlar and fiberglass. One more kind of propeller shaft is manufactured of thermoplastic polyamide, which is rigid and has a higher energy-to-weight ratio. Both generate shafts and screw shafts are employed to drive cars, ships and bikes.

Sliding and tubular yokes are frequent factors of generate shafts. By style, their angles have to be equivalent or intersect to supply the appropriate angle of procedure. Unless the working angles are equivalent, the shaft vibrates twice for each revolution, causing torsional vibrations. The ideal way to stay away from this is to make confident the two yokes are properly aligned. Crucially, these factors have the very same working angle to make sure clean energy flow.

The kind of drive shaft may differ in accordance to the sort of motor. Some are geared, even though other folks are non-geared. In some circumstances, the generate shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be used to management the velocity and direction of the travel. In some applications where linear electricity transmission is not feasible, versatile shafts are a beneficial selection. For illustration, versatile shafts can be utilised in transportable products.

set up

The building of the drive shaft has numerous positive aspects in excess of bare steel. A shaft that is flexible in a number of directions is easier to preserve than a shaft that is rigid in other directions. The shaft body and coupling flange can be created of different materials, and the flange can be manufactured of a various material than the major shaft human body. For illustration, the coupling flange can be created of steel. The primary shaft entire body is if possible flared on at the very least one particular end, and the at minimum 1 coupling flange consists of a very first typically frustoconical projection extending into the flared conclude of the primary shaft human body.

The standard stiffness of fiber-dependent shafts is accomplished by the orientation of parallel fibers together the size of the shaft. Nonetheless, the bending stiffness of this shaft is lowered because of to the change in fiber orientation. Since the fibers continue to vacation in the exact same route from the very first finish to the second stop, the reinforcement that boosts the torsional stiffness of the shaft is not influenced. In distinction, a fiber-primarily based shaft is also adaptable simply because it utilizes ribs that are approximately 90 levels from the centerline of the shaft.

In addition to the helical ribs, the push shaft one hundred may possibly also include reinforcing components. These reinforcing factors keep the structural integrity of the shaft. These reinforcing aspects are referred to as helical ribs. They have ribs on both the outer and internal surfaces. This is to prevent shaft breakage. These factors can also be formed to be flexible adequate to accommodate some of the forces produced by the drive. Shafts can be made employing these techniques and made into worm-like drive shafts.

vibration

The most typical lead to of travel shaft vibration is incorrect set up. There are five frequent types of driveshaft vibration, each and every associated to set up parameters. To prevent this from happening, you ought to recognize what triggers these vibrations and how to fix them. The most frequent kinds of vibration are shown under. This post describes some frequent drive shaft vibration options. It could also be helpful to consider the tips of a professional vibration technician for drive shaft vibration handle.

If you’re not positive if the problem is the driveshaft or the motor, try turning on the stereo. Thicker carpet kits can also mask vibrations. Even so, you ought to contact an skilled as before long as feasible. If vibration persists right after vibration-connected repairs, the driveshaft needs to be changed. If the driveshaft is even now beneath warranty, you can mend it your self.

CV joints are the most frequent trigger of 3rd-order driveshaft vibration. If they are binding or are unsuccessful, they need to have to be replaced. Alternatively, your CV joints could just be misaligned. If it is unfastened, you can check out the CV connector. One more widespread trigger of generate shaft vibration is poor assembly. Improper alignment of the yokes on each finishes of the shaft can result in them to vibrate.

Incorrect trim top can also trigger driveshaft vibration. Appropriate trim height is required to avert travel shaft wobble. Whether or not your motor vehicle is new or outdated, you can perform some fundamental fixes to minimize difficulties. One of these answers involves balancing the travel shaft. First, use the hose clamps to connect the weights to it. Following, connect an ounce of bodyweight to it and spin it. By carrying out this, you decrease the frequency of vibration.

price

The world-wide driveshaft industry is predicted to exceed (xxx) million USD by 2028, growing at a compound annual development charge (CAGR) of XX%. Its soaring growth can be attributed to several elements, like rising urbanization and R&D investments by top market place gamers. The report also consists of an in-depth examination of key industry developments and their affect on the sector. Moreover, the report provides a comprehensive regional examination of the Driveshaft Market place.

The price of replacing the drive shaft depends on the type of restore needed and the lead to of the failure. Standard fix fees selection from $300 to $750. Rear-wheel travel automobiles generally value much more. But entrance-wheel push cars value much less than 4-wheel generate automobiles. You may possibly also decide on to try fixing the driveshaft oneself. Nevertheless, it is important to do your study and make positive you have the needed resources and gear to complete the work properly.

The report also addresses the competitive landscape of the Generate Shafts market place. It involves graphical representations, in depth data, administration procedures, and governance components. Furthermore, it contains a in depth cost evaluation. In addition, the report presents views on the COVID-19 industry and future tendencies. The report also gives worthwhile data to aid you decide how to compete in your sector. When you acquire a report like this, you are adding credibility to your perform.

A high quality driveshaft can enhance your match by guaranteeing length from the tee and strengthening responsiveness. The new content in the shaft development is lighter, more powerful and far more responsive than ever before, so it is getting to be a key portion of the driver. And there are a variety of possibilities to match any budget. The principal factor to think about when buying a shaft is its high quality. Nonetheless, it is essential to notice that high quality doesn’t arrive low-cost and you should constantly pick an axle dependent on what your price range can manage.

China best 124 Front Axle CVD Drive Shaft Axle for Axial SCX24 90081 RC Remote Control Car Model Parts with high quality

Gender: Unisex

Age Selection: 8 to thirteen Many years, fourteen A long time & up

Variety: Automobile

Energy: Battery

Substance: Rubber

Plastic Variety: Computer/PVC

Scale: 1:24, 1:24

Radio Manage Type: RC Passion

Product Variety: 1/24

Merchandise title: SCX24 Entrance Axle CVD

Diameter: 5 cm

Hight: 5cm

G.W/N.W: 5 g

Compatibility: SCX24

Coloration: Picture Shade

Packaging Particulars: For every pcs/ opp Bag.

Products Description Certifications Toy type:Rc Crawler Car Model Up grade PartsScale:1:24Compatibility:SCX24Color:yellowPayment:T/T, PaypalDelivery time:3-7 Times Advocate Goods Business Profile Packing & Supply FAQ FAQQ1: Exactly where is your organization situated? Do you have possess factory?A1: Our manufacturing unit is located in HangZhou Metropolis, China. Yes,we have.Welcome to pay a visit to us.Q2: What’ Scooter Variator Kit Pulley For Kymco 250cc 300cc ATV Motorbike Scooter 22110-KHE7-900 22131-LBA7-900 22131-KHE7-900 s the delivery time?A2: It will just take about 7-thirty times to end an purchase. But the specific time is in accordance to true circumstance.Q3: Can I get sample and how lengthy will it consider?A3: Yes. We can source sample. But you require to shell out for the transport value. Right after getting the payment, we will send out the sample inside 5 times.This autumn: If we can print logo on merchandise?A4: We take to print the tailored logo or personalized bundle.Q5: Can you provide OEM/ODM service?A5: Sure, we are the producer, we are delighted to supply OEM and ODM services to our buyers, but MOQ will be little bigger than retailer quantities.Q6: What delivery approaches will you use?A6: We will provide by Specific shipping (UPS, DHL, FedEx, Aluminum Sliding Window Trolleys Blue White Zinc Plating Solitary Roller Round TNT), Postal parcel, and Sea transportation.Q7: What is your payment?A7: We usually accept payment dependent on T/T,Western Union,Paypal,Alipay,Escrow, Wholesale High Good quality Servo Motor Watertight Motor Modest Planetary Gearbox and Income Gram.It is negotiable.

Why Examining the Travel Shaft is Important

If you listen to clicking noises although driving, your driveshaft might want restore. An skilled mechanic can tell if the sound is coming from 1 facet or equally sides. This dilemma is typically related to the torque converter. Read through on to find out why it really is so critical to have your driveshaft inspected by an car mechanic. Right here are some signs and symptoms to search for. Clicking noises can be triggered by numerous diverse items. You ought to first examine if the noise is coming from the front or the rear of the motor vehicle.

hollow generate shaft

Hollow driveshafts have many positive aspects. They are light-weight and reduce the all round excess weight of the automobile. The premier producer of these components in the planet is CZPT. They also provide light-weight answers for a variety of apps, such as substantial-overall performance axles. CZPT driveshafts are made making use of condition-of-the-art technologies. They supply exceptional quality at competitive rates.

The internal diameter of the hollow shaft reduces the magnitude of the inner forces, thereby minimizing the sum of torque transmitted. In contrast to solid shafts, hollow shafts are getting more powerful. The materials inside of the hollow shaft is a bit lighter, which further reduces its excess weight and total torque. Nevertheless, this also increases its drag at higher speeds. This implies that in many apps hollow driveshafts are not as successful as sound driveshafts.

A typical hollow push shaft consists of a initial rod fourteen and a next rod fourteen on the two sides. The 1st rod is linked with the next rod, and the next rod extends in the rotation direction. The two rods are then friction welded to the central area of the hollow shaft. The frictional warmth generated for the duration of the relative rotation assists to link the two areas. Hollow drive shafts can be employed in inside combustion engines and environmentally-friendly cars.

The major advantage of a hollow driveshaft is bodyweight reduction. The splines of the hollow push shaft can be designed to be scaled-down than the outside diameter of the hollow shaft, which can drastically minimize weight. Hollow shafts are also much less very likely to jam in comparison to strong shafts. Hollow driveshafts are expected to at some point occupy the globe marketplace for automotive driveshafts. Its rewards incorporate gasoline performance and higher flexibility in comparison to sound prop shafts.

Cardan shaft

Cardan shafts are a popular decision in industrial equipment. They are used to transmit energy from one machine to one more and are offered in a assortment of dimensions and designs. They are accessible in a assortment of materials, such as metal, copper, and aluminum. If you strategy to set up one particular of these shafts, it is essential to know the different varieties of Cardan shafts available. To locate the very best option, browse the catalog.

Telescopic or “Cardan” prop shafts, also recognized as U-joints, are excellent for successful torque transfer in between the travel and output system. They are effective, light-weight, and energy-successful. They use innovative approaches, which includes finite element modeling (FEM), to make sure maximum efficiency, excess weight, and performance. In addition, the Cardan shaft has an adjustable length for effortless repositioning.

One more well-known selection for driveshafts is the Cardan shaft, also identified as a driveshaft. The function of the driveshaft is to transfer torque from the engine to the wheels. They are generally utilized in higher-performance automobile engines. Some varieties are made of brass, iron, or metal and have special floor patterns. Cardan shafts are offered in inclined and parallel configurations.

Single Cardan shafts are a common substitute for regular Cardan shafts, but if you are searching for twin Cardan shafts for your vehicle, you will want to decide on the 1310 collection. This kind is fantastic for lifted jeeps and requires a CV-compatible transfer scenario. Some even need axle spacers. The twin Cardan shafts are also made for lifts, which implies it really is a great selection for raising and reducing jeeps.

universal joint

Cardan joints are a good selection for travel shafts when running at a constant pace. Their design and style allows a continuous angular velocity ratio between the input and output shafts. Relying on the software, the suggested velocity limit could range depending on the running angle, transmission power, and software. These suggestions should be based mostly on stress. The highest permissible velocity of the travel shaft is identified by determining the angular acceleration.

Due to the fact gimbal joints will not require grease, they can final a prolonged time but at some point fail. If they are badly lubricated or dry, they can cause metal-to-metallic contact. The exact same is correct for U-joints that do not have oil filling functionality. Although they have a prolonged lifespan, it can be hard to spot warning indications that could show impending joint failure. To avoid this, verify the generate shaft routinely.