Product Description

What are the limitations of using worm screws in mechanical designs?

While worm screws offer several advantages in mechanical designs, they also have some limitations that should be considered. Here are the key limitations of using worm screws:

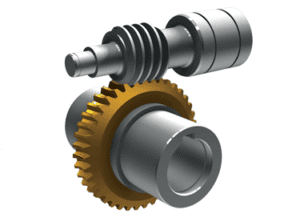

- Lower Mechanical Efficiency: Worm screw mechanisms tend to have lower mechanical efficiency compared to other gear systems. This is primarily due to the sliding contact between the worm screw threads and the worm wheel teeth, which results in higher friction and energy losses. The lower mechanical efficiency can lead to heat generation, reduced power transmission, and decreased overall system efficiency. It’s important to consider the trade-off between the desired gear reduction and the mechanical efficiency requirements of the specific application.

- Limited High-Speed Applications: Worm screws are not well-suited for high-speed applications. The sliding contact and meshing action between the threads and teeth can generate heat and cause wear at high rotational speeds. Additionally, the higher friction and lower mechanical efficiency mentioned earlier can limit the maximum achievable speed of the system. If high-speed operation is a requirement, alternative gear systems, such as spur gears or helical gears, may be more suitable.

- Backlash: Worm screw mechanisms can exhibit a certain amount of backlash, which is the lost motion or clearance between the threads and teeth when changing direction. Backlash can negatively impact precision and positioning accuracy in applications that require tight tolerances. It’s important to consider backlash and implement measures to minimize its effects, such as using anti-backlash mechanisms or incorporating backlash compensation techniques.

- Material Selection: The choice of materials for worm screws is crucial to ensure their durability and performance. Worm screws typically require harder materials to withstand the sliding contact and high contact pressures between the threads and teeth. The selection of suitable materials may increase the manufacturing complexity and cost of the worm screw assembly. Additionally, the choice of materials should consider factors such as compatibility, wear resistance, and the specific operating conditions of the application.

- Load Distribution: In worm screw mechanisms, the load is distributed over a limited number of teeth on the worm wheel. This concentrated load distribution can result in higher stresses and wear on the contacting surfaces. It’s important to consider the load capacity and contact area of the worm wheel teeth to ensure that the assembly can handle the anticipated loads without premature failure or excessive wear.

- Required Lubrication: Proper lubrication is crucial for the smooth operation and longevity of worm screw mechanisms. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces. However, the need for lubrication adds complexity to the design and maintenance of the system. It requires regular monitoring of lubricant levels and periodic lubricant replenishment or replacement. Failure to maintain proper lubrication can result in increased friction, wear, and potential system failure.

Despite these limitations, worm screws continue to be widely used in various mechanical designs due to their unique characteristics and advantages. It’s essential to carefully evaluate the specific requirements and constraints of the application and consider alternative gear systems if the limitations of worm screws pose significant challenges to the desired performance and efficiency.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

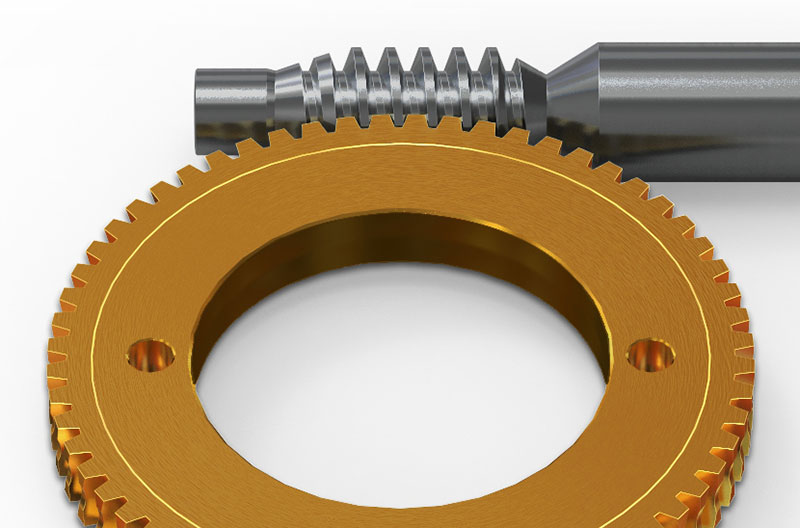

How do you calculate the gear ratio for a worm screw and gear setup?

In a worm screw and gear setup, the gear ratio is determined by the number of teeth on the worm wheel (gear) and the number of threads on the worm screw. The gear ratio represents the relationship between the rotational speed of the worm screw and the resulting rotational speed of the worm wheel. The formula to calculate the gear ratio is as follows:

Gear Ratio = Number of Teeth on Worm Wheel / Number of Threads on Worm Screw

Here’s a step-by-step process to calculate the gear ratio:

- Count the number of teeth on the worm wheel. This can be done by visually inspecting the gear or referring to its specifications.

- Count the number of threads on the worm screw. The threads refer to the number of complete turns or helical grooves wrapped around the cylindrical body of the worm screw.

- Divide the number of teeth on the worm wheel by the number of threads on the worm screw.

- The result of the division is the gear ratio. It represents the number of revolutions of the worm screw required to complete one revolution of the worm wheel.

For example, let’s say the worm wheel has 40 teeth, and the worm screw has 2 threads. Using the formula, we can calculate the gear ratio as follows:

Gear Ratio = 40 teeth / 2 threads = 20

In this case, for every full revolution of the worm screw, the worm wheel will rotate 1/20th of a revolution. This indicates a significant speed reduction, resulting in high torque output at the worm wheel.

It’s important to note that the gear ratio calculated using this formula assumes an ideal scenario without considering factors like friction, efficiency losses, or the pitch diameter of the gears. In practical applications, these factors may affect the actual gear ratio and performance of the worm screw and gear setup.

editor by Dream 2024-11-18

China wholesaler Machine Tools Worm Whirlwind Milling Thread Turning Lathe Machine for Screws

Product Description

What maintenance is required for worm screw gear systems?

Maintaining worm screw gear systems is essential to ensure their smooth operation, longevity, and optimal performance. Here are the key maintenance tasks typically required for worm screw gear systems:

- Lubrication: Proper lubrication is crucial for reducing friction, wear, and heat generation in worm screw gear systems. Regularly monitor lubricant levels and follow the manufacturer’s recommendations for lubrication intervals and types of lubricants to use. Inspect lubricant quality and cleanliness, and replenish or replace the lubricant as needed. Pay attention to proper lubrication in both the worm screw and the worm wheel to ensure efficient torque transmission and minimize wear.

- Cleaning: Regularly clean the worm screw gear system to remove dirt, debris, and contaminants that can accumulate on the threads, teeth, and other contacting surfaces. Use appropriate cleaning methods and solvents recommended by the manufacturer. Ensure that the cleaning process does not damage the components or compromise the lubrication system.

- Inspection: Conduct routine inspections to identify any signs of wear, damage, or misalignment in the worm screw gear system. Check for excessive backlash, abnormal noise, vibration, or irregularities in operation. Inspect the teeth, threads, and other critical areas for signs of wear, pitting, or scoring. If any issues are detected, take appropriate measures to address them promptly, such as adjusting the backlash or replacing worn components.

- Alignment: Proper alignment is crucial for the optimal performance and longevity of worm screw gear systems. Periodically check and adjust the alignment of the worm screw and the worm wheel to ensure smooth and efficient meshing. Misalignment can result in increased friction, wear, and reduced performance. Follow the manufacturer’s guidelines for alignment procedures and use precision measurement tools as necessary.

- Load Distribution: Monitor the load distribution across the teeth of the worm wheel. Uneven load distribution can lead to premature wear and failure of the system. If necessary, adjust loads, redistribute the load by using multiple worm screws, or consider using additional supporting mechanisms to ensure uniform load distribution.

- Temperature Monitoring: Keep an eye on the operating temperature of the worm screw gear system. Excessive heat can indicate problems such as inadequate lubrication, overloading, or inefficiencies. Monitor temperature using appropriate sensors or thermal imaging techniques and take corrective actions if the temperature exceeds recommended limits.

- Periodic Overhaul: Depending on the application and usage conditions, consider scheduling periodic overhauls or maintenance intervals for the worm screw gear system. During these overhauls, disassemble the system, inspect components thoroughly, replace worn or damaged parts, reassemble with proper lubrication, and perform necessary adjustments. The frequency of overhauls will depend on factors such as operating conditions, loads, and manufacturer recommendations.

- Documentation: Maintain proper documentation of maintenance activities, including lubrication schedules, inspection records, repair or replacement history, and any troubleshooting performed. This documentation provides a valuable reference for future maintenance, helps identify recurring issues, and enables better tracking of the system’s performance over time.

It’s important to note that specific maintenance requirements may vary depending on the design, materials, operating conditions, and manufacturer recommendations for the worm screw gear system. Always refer to the manufacturer’s documentation and guidelines for the particular system being used, and consult with experts or maintenance professionals if needed.

Are there different types of worm screws available?

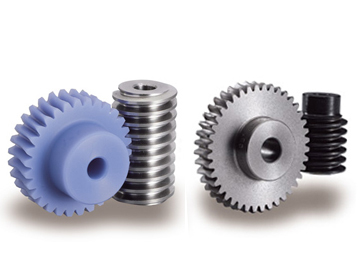

Yes, there are different types of worm screws available to suit various applications and requirements. The design and characteristics of a worm screw can vary based on factors such as the material used, the thread geometry, the type of worm wheel, and the intended application. Here are some common types of worm screws:

- Standard Worm Screws: Standard worm screws are the most commonly used type and are available in a wide range of sizes and materials. They typically have a single-start thread and are made from materials such as steel, stainless steel, or bronze. Standard worm screws are suitable for general-purpose applications where moderate precision and load capacity are required.

- Double-Enveloping Worm Screws: Double-enveloping worm screws, also known as hourglass worm screws, have a unique thread profile that improves contact and load distribution between the worm screw and the worm wheel. This design offers enhanced torque transmission, higher efficiency, and increased load-carrying capacity compared to standard worm screws. Double-enveloping worm screws are often used in heavy-duty applications, such as gearboxes and high-load power transmission systems.

- Low-Lead Worm Screws: Low-lead worm screws have a smaller thread lead angle compared to standard worm screws. This design reduces the amount of sliding contact between the threads of the worm screw and the teeth of the worm wheel, resulting in lower friction and improved efficiency. Low-lead worm screws are commonly used in applications where high efficiency and reduced heat generation are critical, such as in precision machinery and high-speed gear systems.

- Self-Locking Worm Screws: Self-locking worm screws are designed to have a high friction angle between the threads, making them capable of preventing reverse motion or backdriving. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices in certain applications. Self-locking worm screws are commonly used in vertical lift systems, hoists, and other applications where holding the load position is essential.

- High-Precision Worm Screws: High-precision worm screws are manufactured to tighter tolerances and have improved accuracy compared to standard worm screws. They are designed to provide precise positioning and motion control in applications where high accuracy and repeatability are required. High-precision worm screws are often used in CNC machines, robotics, and other precision equipment.

- Customized Worm Screws: In addition to the standard types mentioned above, worm screws can also be customized to meet specific application requirements. Customized worm screws may involve variations in thread geometry, pitch, diameter, materials, or other parameters to suit unique applications or performance specifications.

The selection of the appropriate type of worm screw depends on factors such as the desired load capacity, efficiency requirements, backlash tolerance, positional accuracy, and environmental conditions. It is important to consult with manufacturers, engineers, or experts familiar with worm screw applications to determine the most suitable type for a specific application.

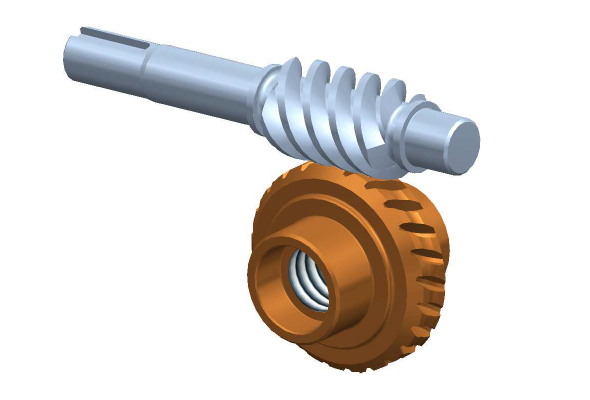

How does a worm screw differ from a regular screw?

In mechanical engineering, a worm screw differs from a regular screw in several key aspects. While both types of screws have helical threads, their designs and functions are distinct. Here are the primary differences between a worm screw and a regular screw:

- Motion Transmission: The primary function of a regular screw is to convert rotary motion into linear motion or vice versa. It typically has a single-threaded or multi-threaded configuration and is used for applications such as fastening, clamping, or lifting. On the other hand, a worm screw is designed to transmit motion and power between non-parallel shafts. It converts rotary motion along its axis into rotary motion perpendicular to its axis by meshing with a worm wheel or gear.

- Gear Ratio: The gear ratio of a worm screw is typically much higher compared to that of a regular screw. The helical teeth of the worm screw and the worm wheel allow for a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a significant rotation of the worm wheel. In contrast, a regular screw does not have a gear ratio and is primarily used for linear motion or force multiplication.

- Orientation and Shaft Arrangement: A regular screw is typically used in applications where the input and output shafts are parallel or nearly parallel. It transfers motion and force along the same axis. In contrast, a worm screw is designed for applications where the input and output shafts are perpendicular to each other. The orientation of the worm screw and the worm wheel allows for motion transmission between non-parallel shafts.

- Self-Locking: One distinctive characteristic of a worm screw is its self-locking property. The helical teeth of the worm screw create a wedging effect that prevents the worm wheel from driving the worm screw. This self-locking feature allows worm screws to hold loads without the need for additional braking mechanisms. Regular screws, on the other hand, do not have this self-locking capability.

- Applications: Regular screws find widespread use in numerous applications, including construction, manufacturing, woodworking, and everyday objects like screws used in fastening. They are primarily employed for linear motion, clamping, or force multiplication. Worm screws, on the other hand, are commonly used in applications that require significant speed reduction, torque multiplication, or motion transmission at right angles. Typical applications include conveyor systems, winches, lifting mechanisms, and heavy machinery.

These differences in design and function make worm screws and regular screws suitable for distinct applications. Regular screws are more commonly used for linear motion and force transfer along parallel or nearly parallel shafts, while worm screws excel in transmitting motion and power between non-parallel shafts with high gear reduction ratios.

editor by Dream 2024-11-18

China best CNC Metal Screw Cutting Worm Process Lathe Machine CNC Lathe with Best Sales

Product Description

CNC Metal Screw Cutting Worm Process Lathe Machine CNC Lathe

| Item | CK6150A |

| Max. swing diameter over bed | Φ500mm |

| Max. swing diameter over cross slide | Φ280mm |

| Processing length | 750mm/1000mm/1500mm |

| Width of the bed | 400mm |

| Diameter of spindle | Φ82mm |

| Spindle taper | 1:20/Φ90 |

| spindle nose | Type of spindle head D-8 |

| Spindle speed | 150-2000rpm |

| Spindle speed step | step-less |

| chuck size | 250mm |

| Tool holder | 4 station |

| Tool bar section | 25X25mm |

| Main motor power | 7.5KW |

| X/Z axis position accuracy | 0.02/0.571mm |

| X/Z axis repeatability | 0.01/0.012mm |

| X/Z axis torque | 6/10N.M |

| X/Z axis travel | 360/750mm/1000mm/1500mm |

| X/Z axis fast feeding speed | 8/10 M/MIN |

| Tail stock sleeve travel | 150mm |

| Tail stock taper | MT5 |

| Dimension | 2410/2660/3160*1560*1730mm |

| Weight | 2800/3200/3500kg |

| Standard Configuration |

| 1.CNC system :GSK928 2. 4-position tools 3.Automatic lubrication pump 4. Manual 3-jaw chuck 5.Manual tailstock 6.auto lubrication system,coolant system,lighting system 7.standard tools box 8.standard packing list 9.operational manual 10.Voltage:3 phase 380v 50HZ(If you need other voltage ,please tell me in advance) |

| Select configure CNC system: KND, Siemens, Fanuc, etc., Hydraulic chuck (solid and hollow), pneumatic chuck, Hydraulic tailstock, pneumatic tailstock, Automatic feeder, Horizontal six-station turret, eight-station turret, tool row, The spindle center height increase. |

Lead Screws and Clamp Style Collars

If you have a lead screw, you’re probably interested in learning about the Acme thread on this type of shaft. You might also be interested in finding out about the Clamp style collars and Ball screw nut. But before you buy a new screw, make sure you understand what the terminology means. Here are some examples of screw shafts:

Acme thread

The standard ACME thread on a screw shaft is made of a metal that is resistant to corrosion and wear. It is used in a variety of applications. An Acme thread is available in a variety of sizes and styles. General purpose Acme threads are not designed to handle external radial loads and are supported by a shaft bearing and linear guide. Their design is intended to minimize the risk of flank wedging, which can cause friction forces and wear. The Centralizing Acme thread standard caters to applications without radial support and allows the thread to come into contact before its flanks are exposed to radial loads.

The ACME thread was first developed in 1894 for machine tools. While the acme lead screw is still the most popular screw in the US, European machines use the Trapezoidal Thread (Metric Acme). The acme thread is a stronger and more resilient alternative to square threads. It is also easier to cut than square threads and can be cut by using a single-point threading die.

Similarly to the internal threads, the metric versions of Acme are similar to their American counterparts. The only difference is that the metric threads are generally wider and are used more frequently in industrial settings. However, the metric-based screw threads are more common than their American counterparts worldwide. In addition, the Acme thread on screw shafts is used most often on external gears. But there is still a small minority of screw shafts that are made with a metric thread.

ACME screws provide a variety of advantages to users, including self-lubrication and reduced wear and tear. They are also ideal for vertical applications, where a reduced frictional force is required. In addition, ACME screws are highly resistant to back-drive and minimize the risk of backlash. Furthermore, they can be easily checked with readily available thread gauges. So, if you’re looking for a quality ACME screw for your next industrial project, look no further than ACME.

Lead screw coatings

The properties of lead screw materials affect their efficiency. These materials have high anti-corrosion, thermal resistance, and self-lubrication properties, which eliminates the need for lubrication. These coating materials include polytetrafluoroethylene (PFE), polyether ether ketone (PEK), and Vespel. Other desirable properties include high tensile strength, corrosion resistance, and rigidity.

The most common materials for lead screws are carbon steel, stainless steel, and aluminum. Lead screw coatings can be PTFE-based to withstand harsh environments and remove oil and grease. In addition to preventing corrosion, lead screw coatings improve the life of polymer parts. Lead screw assembly manufacturers offer a variety of customization options for their lead screw, including custom-molded nuts, thread forms, and nut bodies.

Lead screws are typically measured in rpm, or revolutions per minute. The PV curve represents the inverse relationship between contact surface pressure and sliding velocity. This value is affected by the material used in the construction of the screw, lubrication conditions, and end fixity. The critical speed of lead screws is determined by their length and minor diameter. End fixity refers to the support for the screw and affects its rigidity and critical speed.

The primary purpose of lead screws is to enable smooth movement. To achieve this, lead screws are usually preloaded with axial load, enabling consistent contact between a screw’s filets and nuts. Lead screws are often used in linear motion control systems and feature a large area of sliding contact between male and female threads. Lead screws can be manually operated or mortised and are available in a variety of sizes and materials. The materials used for lead screws include stainless steel and bronze, which are often protected by a PTFE type coating.

These screws are made of various materials, including stainless steel, bronze, and various plastics. They are also made to meet specific requirements for environmental conditions. In addition to lead screws, they can be made of stainless steel, aluminum, and carbon steel. Surface coatings can improve the screw’s corrosion resistance, while making it more wear resistant in tough environments. A screw that is coated with PTFE will maintain its anti-corrosion properties even in tough environments.

Clamp style collars

The screw shaft clamp style collar is a basic machine component, which is attached to the shaft via multiple screws. These collars act as mechanical stops, load bearing faces, or load transfer points. Their simple design makes them easy to install. This article will discuss the pros and cons of this style of collar. Let’s look at what you need to know before choosing a screw shaft clamp style collar. Here are some things to keep in mind.

Clamp-style shaft collars are a versatile mounting option for shafts. They have a recessed screw that fully engages the thread for secure locking. Screw shaft clamp collars come in different styles and can be used in both drive and power transmission applications. Listed below are the main differences between these 2 styles of collars. They are compatible with all types of shafts and are able to handle axial loads of up to 5500 pounds.

Clamp-style shaft collars are designed to prevent the screw from accidentally damaging the shaft when tightened. They can be tightened with a set screw to counteract the initial clamping force and prevent the shaft from coming loose. However, when tightening the screw, you should use a torque wrench. Using a set screw to tighten a screw shaft collar can cause it to warp and reduce the surface area that contacts the shaft.

Another key advantage to Clamp-style shaft collars is that they are easy to install. Clamp-style collars are available in one-piece and two-piece designs. These collars lock around the shaft and are easy to remove and install. They are ideal for virtually any shaft and can be installed without removing any components. This type of collar is also recommended for those who work on machines with sensitive components. However, be aware that the higher the OD, the more difficult it is to install and remove the collar.

Screw shaft clamp style collars are usually one-piece. A two-piece collar is easier to install than a one-piece one. The two-piece collars provide a more effective clamping force, as they use the full seating torque. Two-piece collars have the added benefit of being easy to install because they require no tools to install. You can disassemble one-piece collars before installing a two-piece collar.

Ball screw nut

The proper installation of a ball screw nut requires that the nut be installed on the center of the screw shaft. The return tubes of the ball nut must be oriented upward so that the ball nut will not overtravel. The adjusting nut must be tightened against a spacer or spring washer, then the nut is placed on the screw shaft. The nut should be rotated several times in both directions to ensure that it is centered.

Ball screw nuts are typically manufactured with a wide range of preloads. Large preloads are used to increase the rigidity of a ball screw assembly and prevent backlash, the lost motion caused by a clearance between the ball and nut. Using a large amount of preload can lead to excessive heat generation. The most common preload for ball screw nuts is 1 to 3%. This is usually more than enough to prevent backlash, but a higher preload will increase torque requirements.

The diameter of a ball screw is measured from its center, called the ball circle diameter. This diameter represents the distance a ball will travel during 1 rotation of the screw shaft. A smaller diameter means that there are fewer balls to carry the load. Larger leads mean longer travels per revolution and higher speeds. However, this type of screw cannot carry a greater load capacity. Increasing the length of the ball nut is not practical, due to manufacturing constraints.

The most important component of a ball screw is a ball bearing. This prevents excessive friction between the ball and the nut, which is common in lead-screw and nut combinations. Some ball screws feature preloaded balls, which avoid “wiggle” between the nut and the ball. This is particularly desirable in applications with rapidly changing loads. When this is not possible, the ball screw will experience significant backlash.

A ball screw nut can be either single or multiple circuits. Single or multiple-circuit ball nuts can be configured with 1 or 2 independent closed paths. Multi-circuit ball nuts have 2 or more circuits, making them more suitable for heavier loads. Depending on the application, a ball screw nut can be used for small clearance assemblies and compact sizes. In some cases, end caps and deflectors may be used to feed the balls back to their original position.

China Best Sales Machinery Repair Shops Automatic 480V Economical CNC Lathe Heavy Duty OEM CNC Machine Viet Nam 8000 RPM Max Speed with high quality

Problem: New

Kind: VERTICAL

Yr: 10

Max. Size of Workpiece (mm): a thousand mm

Max. Spindle Pace (r.p.m): 8000 r.p.m

Machining Capacity: Hefty Responsibility

Spindle Bore(mm): m’m

Width of mattress (mm): mm

Spindle Motor Energy(kW): 100

No. of Spindles: 4

Max. Turned Size (mm): a thousand

Variety of Axes: 4

Vacation (X Axis)(mm): mm

Travel (Z Axis)(mm): mm

Positioning Precision (mm): .01 mm

Repeatability (X/Y/Z) (mm): .01

Dimension(L*W*H): 2*3*two

Design Number: 116

Voltage: 480

CNC Management Method: MITSUBISHI

Toolpost Brand: Hydex

Instrument Publish Stations: None

Bodyweight (KG): 800

Guarantee: 1 12 months

Applicable Industries: Garment Retailers, Constructing Material Retailers, Machinery Fix Stores, Production Plant, Food & Beverage Manufacturing facility, Farms, Home Use, Retail, Printing Outlets, Building works , Energy & Mining

Essential Marketing Points: Multifunctional

Showroom Location: None

Marketing and advertising Sort: Hot Merchandise 2019

Equipment Take a look at Report: Not Obtainable

Video clip outgoing-inspection: Not Available

Guarantee of main elements: Not Offered

Main Components: Gear

CNC or Not: CNC

Automated Grade: Computerized

Equipment Kind: Lathe Device CNC

Function: Machining Metal

Power (kW): eleven

Max. Swing Diameter (mm): a thousand mm

Product type: Economical CNC Lathe

Precision: Higher Precision

Soon after-sales Support Offered: Free of charge spare parts

Packaging Particulars: At the ask for of buyers

Port: Cat Lai Port, Ho Chi Minh City, Viet Nam

Specification itemvalueConditionNewTypeVERTICALYear10Max. Length of Workpiece (mm)a thousand mmMax. Spindle Velocity (r.p.m)8000r.p.mMachining CapacityHeavy DutySpindle Bore(mm) m’mWidth of mattress (mm)0mmSpindle Motor Electrical power(kW)100No. of Spindles4Max. Turned Size (mm)1000Number of Axes4Travel (X Axis)(mm)0mmTravel (Z Axis)(mm)0mmPositioning Precision (mm).01 mmRepeatability (X/Y/Z) (mm).01Place of OriginVietnamHo Chi Minh CityDimension(L*W*H)2*3*2Brand NameManufacturing CNC mechanical processing VietnamModel Number116Voltage480CNC Manage SystemMITSUBISHIToolpost BrandHydexTool Submit StationsNoneWeight (KG)800Warranty1 YearApplicable IndustriesGarment Shops, Creating Content Outlets, NM32 oilless CZPT bushing,9834-032 oilless CZPT bushes with collar, DIN 9834 ISO 9448 bronze graphite bearing Machinery Restore Shops, Manufacturing Plant, Foodstuff & Beverage Factory, Farms, Property Use, Retail, Printing Shops, Construction performs , Power & MiningKey Promoting PointsMultifunctionalShowroom LocationNoneMarketing TypeHot Merchandise 2019Machinery Take a look at ReportNot AvailableVideo outgoing-inspectionNot AvailableWarranty of core componentsNot AvailableCore ComponentsGearCNC or NotCNCAutomatic GradeAutomaticMachine TypeLathe Machine CNCFunctionMachining MetalPower (kW)11Max. Swing Diameter (mm)1000 mmProduct typeEconomical CNC LathePrecisionHigh PrecisionAfter-revenue Provider ProvidedFree spare elements FAQ 1. who are we?We are dependent in Ho Chi Minh, Vietnam, start off from 2017,promote to North The united states(fifty.00%),Jap Asia(twenty.00%), Hot sale new 250cc racing shaft push 2 seat inexpensive go kart k3 k5 k7 s for grown ups Western Europe(20.00%),Southeast Asia(10.00%). There are total about 501-a thousand men and women in our office.2. how can we promise quality?Always a pre-creation sample ahead of mass productionAlways closing Inspection prior to shipment3.what can you purchase from us?Ceramic Processing,Digital,Molding Casting,Mechanical CNC,Plastic4. why ought to you acquire from us not from other suppliers?- We work in 2 principal areas: 1) Making and processing goods related to CNC precision mechanics and items connected to molding in big amount. 2) Layout, manufacture and assemble digital items and electronic elements.5. what companies can we give?Recognized Shipping Conditions: FOB;Accepted Payment Currency:USD,EUR,JPYAccepted Payment Kind: T/T,L/CLanguage Spoken:English

Manual to Travel Shafts and U-Joints

If you’re worried about the performance of your car’s driveshaft, you happen to be not by yourself. A lot of auto proprietors are unaware of the warning symptoms of a failed driveshaft, but knowing what to look for can assist you keep away from high priced repairs. Below is a quick guide on push shafts, U-joints and servicing intervals. Detailed below are key points to think about just before changing a car driveshaft.

Signs and symptoms of Driveshaft Failure

Pinpointing a defective driveshaft is straightforward if you’ve at any time heard a odd noise from beneath your automobile. These appears are caused by worn U-joints and bearings supporting the travel shaft. When they fail, the travel shafts quit rotating appropriately, creating a clanking or squeaking audio. When this occurs, you could hear sounds from the side of the steering wheel or floor.

In addition to noise, a defective driveshaft can lead to your auto to swerve in limited corners. It can also guide to suspended bindings that restrict overall control. Consequently, you ought to have these symptoms checked by a mechanic as shortly as you observe them. If you recognize any of the signs over, your up coming action must be to tow your vehicle to a mechanic. To steer clear of further trouble, make certain you’ve got taken safeguards by examining your car’s oil level.

In addition to these signs and symptoms, you need to also look for any noise from the drive shaft. The 1st point to look for is the squeak. This was caused by severe damage to the U-joint attached to the generate shaft. In addition to sounds, you must also search for rust on the bearing cap seals. In severe circumstances, your vehicle can even shudder when accelerating.

Vibration while driving can be an early warning sign of a driveshaft failure. Vibration can be because of to worn bushings, stuck sliding yokes, or even springs or bent yokes. Too much torque can be induced by a worn middle bearing or a ruined U-joint. The motor vehicle could make uncommon noises in the chassis program.

If you discover these indications, it really is time to consider your automobile to a mechanic. You ought to check frequently, specially hefty cars. If you are not confident what’s leading to the sounds, check out your car’s transmission, motor, and rear differential. If you suspect that a driveshaft demands to be replaced, a licensed mechanic can replace the driveshaft in your auto.

Push shaft sort

Driveshafts are used in numerous distinct kinds of cars. These incorporate four-wheel push, entrance-motor rear-wheel generate, bikes and boats. Each and every sort of generate shaft has its possess goal. Beneath is an overview of the three most frequent kinds of drive shafts:

The driveshaft is a circular, elongated shaft that transmits torque from the engine to the wheels. Generate shafts often have several joints to compensate for modifications in duration or angle. Some generate shafts also include connecting shafts and internal continual velocity joints. Some also contain torsional dampers, spline joints, and even prismatic joints. The most crucial factor about the driveshaft is that it plays a essential role in transmitting torque from the engine to the wheels.

The travel shaft requirements to be the two light and sturdy to transfer torque. Although steel is the most typically employed content for automotive driveshafts, other supplies this sort of as aluminum, composites, and carbon fiber are also generally utilized. It all relies upon on the function and size of the motor vehicle. Precision Production is a very good source for OEM merchandise and OEM driveshafts. So when you happen to be hunting for a new driveshaft, hold these variables in head when acquiring.

Cardan joints are yet another widespread drive shaft. A common joint, also known as a U-joint, is a flexible coupling that permits 1 shaft to drive the other at an angle. This type of drive shaft allows electricity to be transmitted although the angle of the other shaft is constantly shifting. Even though a gimbal is a excellent alternative, it is not a best remedy for all purposes.

CZPT, Inc. has state-of-the-art equipment to provider all varieties of generate shafts, from modest autos to race vehicles. They provide a assortment of wants, which includes racing, market and agriculture. Whether or not you need a new drive shaft or a simple adjustment, the workers at CZPT can meet up with all your requirements. You will be back on the road soon!

U-joint

If your vehicle yoke or u-joint demonstrates signs of wear, it’s time to change them. The best way to substitute them is to adhere to the actions below. Use a massive flathead screwdriver to test. If you really feel any movement, the U-joint is faulty. Also, inspect the bearing caps for harm or rust. If you can’t discover the u-joint wrench, try examining with a flashlight.

When inspecting U-joints, make sure they are properly lubricated and lubricated. If the joint is dry or improperly lubricated, it can speedily fail and cause your vehicle to squeak even though driving. Another sign that a joint is about to are unsuccessful is a sudden, abnormal whine. Examine your u-joints every 12 months or so to make positive they are in proper doing work order.

Whether your u-joint is sealed or lubricated will depend on the make and model of your motor vehicle. When your vehicle is off-road, you need to put in lubricable U-joints for durability and longevity. A new driveshaft or derailleur will price far more than a U-joint. Also, if you do not have a good understanding of how to change them, you may possibly require to do some transmission operate on your car.

When replacing the U-joint on the generate shaft, be certain to decide on an OEM substitute anytime achievable. While you can simply mend or change the original head, if the u-joint is not lubricated, you may possibly want to substitute it. A damaged gimbal joint can lead to problems with your car’s transmission or other crucial parts. Changing your car’s U-joint early can make sure its lengthy-time period performance.

Yet another alternative is to use two CV joints on the generate shaft. Employing several CV joints on the generate shaft will help you in conditions where alignment is challenging or working angles do not match. This type of driveshaft joint is far more high-priced and complicated than a U-joint. The down sides of making use of multiple CV joints are added duration, bodyweight, and diminished functioning angle. There are numerous reasons to use a U-joint on a drive shaft.

upkeep interval

Checking U-joints and slip joints is a crucial part of regimen upkeep. Most autos are equipped with lube fittings on the driveshaft slip joint, which must be checked and lubricated at every oil modify. CZPT specialists are nicely-versed in axles and can effortlessly discover a negative U-joint based mostly on the sound of acceleration or shifting. If not fixed properly, the travel shaft can drop off, necessitating expensive repairs.

Oil filters and oil adjustments are other components of a vehicle’s mechanical program. To avert rust, the oil in these areas have to be changed. The identical goes for transmission. Your vehicle’s driveshaft must be inspected at minimum each and every sixty,000 miles. The vehicle’s transmission and clutch should also be checked for dress in. Other elements that ought to be checked include PCV valves, oil traces and connections, spark plugs, tire bearings, steering gearboxes and brakes.

If your vehicle has a manual transmission, it is greatest to have it serviced by CZPT’s East Lexington professionals. These services need to be performed every single two to 4 many years or each 24,000 miles. For very best results, refer to the owner’s handbook for advisable upkeep intervals. CZPT technicians are seasoned in axles and differentials. Typical routine maintenance of your drivetrain will hold it in very good functioning buy.