Product Description

TXR Series Sleeve Type Single Nut Ball Screw (C5/Ct7/Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of TXR series(sleeve type single nut ball screw)are based on C5,Ct7 and Ct10(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5),0.02(Ct7) and 0.05mm or less(Ct10).

Material & Surface Hardness

TXR series (sleeve type single nut ball screw) of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shape of the shaft end of the TXR series (sleeve type single nut ball screws) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5 |

|---|---|

| Screw Diameter: | 16mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Nut Type: | Sleeve Type Single Nut |

| Customization: |

Available

|

|

|---|

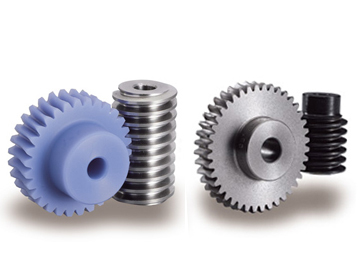

What maintenance is required for worm screw gear systems?

Maintaining worm screw gear systems is essential to ensure their smooth operation, longevity, and optimal performance. Here are the key maintenance tasks typically required for worm screw gear systems:

- Lubrication: Proper lubrication is crucial for reducing friction, wear, and heat generation in worm screw gear systems. Regularly monitor lubricant levels and follow the manufacturer’s recommendations for lubrication intervals and types of lubricants to use. Inspect lubricant quality and cleanliness, and replenish or replace the lubricant as needed. Pay attention to proper lubrication in both the worm screw and the worm wheel to ensure efficient torque transmission and minimize wear.

- Cleaning: Regularly clean the worm screw gear system to remove dirt, debris, and contaminants that can accumulate on the threads, teeth, and other contacting surfaces. Use appropriate cleaning methods and solvents recommended by the manufacturer. Ensure that the cleaning process does not damage the components or compromise the lubrication system.

- Inspection: Conduct routine inspections to identify any signs of wear, damage, or misalignment in the worm screw gear system. Check for excessive backlash, abnormal noise, vibration, or irregularities in operation. Inspect the teeth, threads, and other critical areas for signs of wear, pitting, or scoring. If any issues are detected, take appropriate measures to address them promptly, such as adjusting the backlash or replacing worn components.

- Alignment: Proper alignment is crucial for the optimal performance and longevity of worm screw gear systems. Periodically check and adjust the alignment of the worm screw and the worm wheel to ensure smooth and efficient meshing. Misalignment can result in increased friction, wear, and reduced performance. Follow the manufacturer’s guidelines for alignment procedures and use precision measurement tools as necessary.

- Load Distribution: Monitor the load distribution across the teeth of the worm wheel. Uneven load distribution can lead to premature wear and failure of the system. If necessary, adjust loads, redistribute the load by using multiple worm screws, or consider using additional supporting mechanisms to ensure uniform load distribution.

- Temperature Monitoring: Keep an eye on the operating temperature of the worm screw gear system. Excessive heat can indicate problems such as inadequate lubrication, overloading, or inefficiencies. Monitor temperature using appropriate sensors or thermal imaging techniques and take corrective actions if the temperature exceeds recommended limits.

- Periodic Overhaul: Depending on the application and usage conditions, consider scheduling periodic overhauls or maintenance intervals for the worm screw gear system. During these overhauls, disassemble the system, inspect components thoroughly, replace worn or damaged parts, reassemble with proper lubrication, and perform necessary adjustments. The frequency of overhauls will depend on factors such as operating conditions, loads, and manufacturer recommendations.

- Documentation: Maintain proper documentation of maintenance activities, including lubrication schedules, inspection records, repair or replacement history, and any troubleshooting performed. This documentation provides a valuable reference for future maintenance, helps identify recurring issues, and enables better tracking of the system’s performance over time.

It’s important to note that specific maintenance requirements may vary depending on the design, materials, operating conditions, and manufacturer recommendations for the worm screw gear system. Always refer to the manufacturer’s documentation and guidelines for the particular system being used, and consult with experts or maintenance professionals if needed.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

How do you calculate the gear ratio for a worm screw and gear setup?

In a worm screw and gear setup, the gear ratio is determined by the number of teeth on the worm wheel (gear) and the number of threads on the worm screw. The gear ratio represents the relationship between the rotational speed of the worm screw and the resulting rotational speed of the worm wheel. The formula to calculate the gear ratio is as follows:

Gear Ratio = Number of Teeth on Worm Wheel / Number of Threads on Worm Screw

Here’s a step-by-step process to calculate the gear ratio:

- Count the number of teeth on the worm wheel. This can be done by visually inspecting the gear or referring to its specifications.

- Count the number of threads on the worm screw. The threads refer to the number of complete turns or helical grooves wrapped around the cylindrical body of the worm screw.

- Divide the number of teeth on the worm wheel by the number of threads on the worm screw.

- The result of the division is the gear ratio. It represents the number of revolutions of the worm screw required to complete one revolution of the worm wheel.

For example, let’s say the worm wheel has 40 teeth, and the worm screw has 2 threads. Using the formula, we can calculate the gear ratio as follows:

Gear Ratio = 40 teeth / 2 threads = 20

In this case, for every full revolution of the worm screw, the worm wheel will rotate 1/20th of a revolution. This indicates a significant speed reduction, resulting in high torque output at the worm wheel.

It’s important to note that the gear ratio calculated using this formula assumes an ideal scenario without considering factors like friction, efficiency losses, or the pitch diameter of the gears. In practical applications, these factors may affect the actual gear ratio and performance of the worm screw and gear setup.

editor by Dream 2024-05-15

China manufacturer CHINAMFG C10 Class Rolled Ball Screw with 2.5mm Lead for CNC Router (GLR Series, Lead: 2.5mm, Shaft: 8mm)

Product Description

GLR Series Single Nut Ball Screw with Metric Thread (C5/Ct7/Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of GLR series(single nut ball screw with metric thread)are based on C5,Ct7 and Ct10(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5),0.02(Ct7) and 0.05mm or less(Ct10).

Material & Surface Hardness

GLR series (single nut ball screw with metric thread)of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shaft end shape of the GLR series (single nut ball screw with metric thread) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C10 |

|---|---|

| Screw Diameter: | 8mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 3-Row |

| Nut Type: | Single Nut Ball Screw with Metric Thread |

| Customization: |

Available

|

|

|---|

What are the limitations of using worm screws in mechanical designs?

While worm screws offer several advantages in mechanical designs, they also have some limitations that should be considered. Here are the key limitations of using worm screws:

- Lower Mechanical Efficiency: Worm screw mechanisms tend to have lower mechanical efficiency compared to other gear systems. This is primarily due to the sliding contact between the worm screw threads and the worm wheel teeth, which results in higher friction and energy losses. The lower mechanical efficiency can lead to heat generation, reduced power transmission, and decreased overall system efficiency. It’s important to consider the trade-off between the desired gear reduction and the mechanical efficiency requirements of the specific application.

- Limited High-Speed Applications: Worm screws are not well-suited for high-speed applications. The sliding contact and meshing action between the threads and teeth can generate heat and cause wear at high rotational speeds. Additionally, the higher friction and lower mechanical efficiency mentioned earlier can limit the maximum achievable speed of the system. If high-speed operation is a requirement, alternative gear systems, such as spur gears or helical gears, may be more suitable.

- Backlash: Worm screw mechanisms can exhibit a certain amount of backlash, which is the lost motion or clearance between the threads and teeth when changing direction. Backlash can negatively impact precision and positioning accuracy in applications that require tight tolerances. It’s important to consider backlash and implement measures to minimize its effects, such as using anti-backlash mechanisms or incorporating backlash compensation techniques.

- Material Selection: The choice of materials for worm screws is crucial to ensure their durability and performance. Worm screws typically require harder materials to withstand the sliding contact and high contact pressures between the threads and teeth. The selection of suitable materials may increase the manufacturing complexity and cost of the worm screw assembly. Additionally, the choice of materials should consider factors such as compatibility, wear resistance, and the specific operating conditions of the application.

- Load Distribution: In worm screw mechanisms, the load is distributed over a limited number of teeth on the worm wheel. This concentrated load distribution can result in higher stresses and wear on the contacting surfaces. It’s important to consider the load capacity and contact area of the worm wheel teeth to ensure that the assembly can handle the anticipated loads without premature failure or excessive wear.

- Required Lubrication: Proper lubrication is crucial for the smooth operation and longevity of worm screw mechanisms. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces. However, the need for lubrication adds complexity to the design and maintenance of the system. It requires regular monitoring of lubricant levels and periodic lubricant replenishment or replacement. Failure to maintain proper lubrication can result in increased friction, wear, and potential system failure.

Despite these limitations, worm screws continue to be widely used in various mechanical designs due to their unique characteristics and advantages. It’s essential to carefully evaluate the specific requirements and constraints of the application and consider alternative gear systems if the limitations of worm screws pose significant challenges to the desired performance and efficiency.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

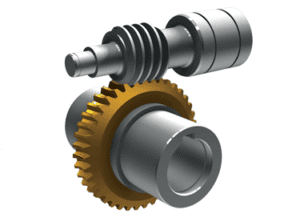

How does a worm screw differ from a regular screw?

In mechanical engineering, a worm screw differs from a regular screw in several key aspects. While both types of screws have helical threads, their designs and functions are distinct. Here are the primary differences between a worm screw and a regular screw:

- Motion Transmission: The primary function of a regular screw is to convert rotary motion into linear motion or vice versa. It typically has a single-threaded or multi-threaded configuration and is used for applications such as fastening, clamping, or lifting. On the other hand, a worm screw is designed to transmit motion and power between non-parallel shafts. It converts rotary motion along its axis into rotary motion perpendicular to its axis by meshing with a worm wheel or gear.

- Gear Ratio: The gear ratio of a worm screw is typically much higher compared to that of a regular screw. The helical teeth of the worm screw and the worm wheel allow for a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a significant rotation of the worm wheel. In contrast, a regular screw does not have a gear ratio and is primarily used for linear motion or force multiplication.

- Orientation and Shaft Arrangement: A regular screw is typically used in applications where the input and output shafts are parallel or nearly parallel. It transfers motion and force along the same axis. In contrast, a worm screw is designed for applications where the input and output shafts are perpendicular to each other. The orientation of the worm screw and the worm wheel allows for motion transmission between non-parallel shafts.

- Self-Locking: One distinctive characteristic of a worm screw is its self-locking property. The helical teeth of the worm screw create a wedging effect that prevents the worm wheel from driving the worm screw. This self-locking feature allows worm screws to hold loads without the need for additional braking mechanisms. Regular screws, on the other hand, do not have this self-locking capability.

- Applications: Regular screws find widespread use in numerous applications, including construction, manufacturing, woodworking, and everyday objects like screws used in fastening. They are primarily employed for linear motion, clamping, or force multiplication. Worm screws, on the other hand, are commonly used in applications that require significant speed reduction, torque multiplication, or motion transmission at right angles. Typical applications include conveyor systems, winches, lifting mechanisms, and heavy machinery.

These differences in design and function make worm screws and regular screws suitable for distinct applications. Regular screws are more commonly used for linear motion and force transfer along parallel or nearly parallel shafts, while worm screws excel in transmitting motion and power between non-parallel shafts with high gear reduction ratios.

editor by Dream 2024-04-19

China Good quality CHINAMFG Rolled Ball Screw with High Precision for CNC Router (BSD Series, Lead: 2mm, Shaft: 8mm)

Product Description

BSD Series Stepped Cold Rolled Ball Screw (C5/Ct7)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of BSD series(standard stepped cold rolled ball screw) are based on C5 and Ct7(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5) and 0.02mm or less(Ct7).

Material & Surface Hardness

BSD series (Standard Stepped cold rolled ball screw) of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shape of the shaft end of the BSD series (stepped cold rolled ball screw) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5/C7 |

|---|---|

| Screw Diameter: | 8mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 3-Row |

| Nut Type: | Stepped Type |

| Customization: |

Available

|

|

|---|

What are the limitations of using worm screws in mechanical designs?

While worm screws offer several advantages in mechanical designs, they also have some limitations that should be considered. Here are the key limitations of using worm screws:

- Lower Mechanical Efficiency: Worm screw mechanisms tend to have lower mechanical efficiency compared to other gear systems. This is primarily due to the sliding contact between the worm screw threads and the worm wheel teeth, which results in higher friction and energy losses. The lower mechanical efficiency can lead to heat generation, reduced power transmission, and decreased overall system efficiency. It’s important to consider the trade-off between the desired gear reduction and the mechanical efficiency requirements of the specific application.

- Limited High-Speed Applications: Worm screws are not well-suited for high-speed applications. The sliding contact and meshing action between the threads and teeth can generate heat and cause wear at high rotational speeds. Additionally, the higher friction and lower mechanical efficiency mentioned earlier can limit the maximum achievable speed of the system. If high-speed operation is a requirement, alternative gear systems, such as spur gears or helical gears, may be more suitable.

- Backlash: Worm screw mechanisms can exhibit a certain amount of backlash, which is the lost motion or clearance between the threads and teeth when changing direction. Backlash can negatively impact precision and positioning accuracy in applications that require tight tolerances. It’s important to consider backlash and implement measures to minimize its effects, such as using anti-backlash mechanisms or incorporating backlash compensation techniques.

- Material Selection: The choice of materials for worm screws is crucial to ensure their durability and performance. Worm screws typically require harder materials to withstand the sliding contact and high contact pressures between the threads and teeth. The selection of suitable materials may increase the manufacturing complexity and cost of the worm screw assembly. Additionally, the choice of materials should consider factors such as compatibility, wear resistance, and the specific operating conditions of the application.

- Load Distribution: In worm screw mechanisms, the load is distributed over a limited number of teeth on the worm wheel. This concentrated load distribution can result in higher stresses and wear on the contacting surfaces. It’s important to consider the load capacity and contact area of the worm wheel teeth to ensure that the assembly can handle the anticipated loads without premature failure or excessive wear.

- Required Lubrication: Proper lubrication is crucial for the smooth operation and longevity of worm screw mechanisms. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces. However, the need for lubrication adds complexity to the design and maintenance of the system. It requires regular monitoring of lubricant levels and periodic lubricant replenishment or replacement. Failure to maintain proper lubrication can result in increased friction, wear, and potential system failure.

Despite these limitations, worm screws continue to be widely used in various mechanical designs due to their unique characteristics and advantages. It’s essential to carefully evaluate the specific requirements and constraints of the application and consider alternative gear systems if the limitations of worm screws pose significant challenges to the desired performance and efficiency.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

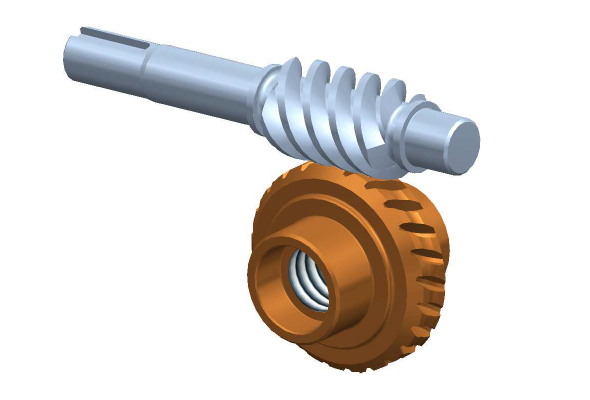

How does a worm screw mechanism work?

A worm screw mechanism, also known as a worm gear mechanism, is a type of power transmission system that consists of a worm screw and a worm wheel. It is designed to transmit motion and power between non-parallel shafts. The mechanism works based on the interaction between the helical threads of the worm screw and the teeth of the worm wheel. Here’s a detailed explanation of how a worm screw mechanism works:

- Structure: The worm screw is a cylindrical shaft with a helical thread wrapped around it, resembling a screw. The worm wheel, also known as a worm gear, is a gear with teeth that mesh with the threads of the worm screw. The orientation of the worm screw and the worm wheel is such that the axes of rotation are perpendicular to each other.

- Motion Transmission: When the worm screw is rotated, its helical threads engage with the teeth of the worm wheel. As the worm screw rotates, it drives the worm wheel to rotate as well. The helical shape of the worm screw and the teeth of the worm wheel allow for motion transmission perpendicular to the axis of the worm screw.

- Gear Reduction: One of the key characteristics of a worm screw mechanism is its ability to provide a significant gear reduction. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a substantial rotation of the worm wheel. The gear reduction enables the worm screw mechanism to generate high torque output at the worm wheel.

- Self-Locking: A notable feature of the worm screw mechanism is its self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel. This means that the worm wheel cannot easily rotate the worm screw. Instead, the worm screw tends to hold its position without the need for additional braking mechanisms. The self-locking feature makes the worm screw mechanism suitable for applications that require holding loads in a fixed position.

- Efficiency and Backlash: The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. Additionally, worm screw mechanisms may exhibit a certain amount of backlash, which refers to the slight play or clearance between the threads and teeth. Backlash can affect precision and introduce a small amount of lost motion in the system.

- Applications: Worm screw mechanisms find applications in various industries and machinery where motion transmission at right angles and high gear reduction ratios are required. Common applications include conveyor systems, lifting mechanisms, winches, automotive steering systems, robotics, and machine tools.

The worm screw mechanism offers a unique combination of motion transmission, gear reduction, and self-locking capabilities, making it suitable for specific applications where precise control, high torque output, and the ability to hold loads are essential.

editor by CX 2024-04-12

China Professional Cheap Price Ball Screw for 3D CNC Router Machine Ballscrew with Free Design Custom

Product Description

Product Description

| Brand | WF |

| Material | S55C alloy steel, 50CrMo4, SCM420H |

| Diameter | 8-80mm |

| Item | SFNI/SFNU/SFH/SFY/SFS/DFS/SFV/DFV/SFI/DFI/SFU/DFU/SFM/SFK/SCI/BSH |

Details

PARAMETERS

- STRUCTURE

DATA DETAILS

MATCH

PACKING & DELIVERY

Company Introduction

HangZhou CZPT Precision Machinery Co., Ltd. established in 2, HangZhou, P.R.C

http://chromedbars

http://chromedbars

Screw Shaft Types

A screw shaft is a cylindrical part that turns. Depending on its size, it is able to drive many different types of devices. The following information outlines the different types of screws, including their sizes, material, function, and applications. To help you select the right screw shaft, consider the following factors:

Size

A screw can come in a variety of shapes and sizes, ranging from a quarter to a quarter-inch in diameter. A screw is a cylindrical shaft with an inclined plane wrapped around it, and its main function is to fasten objects together by translating torque into a linear force. This article will discuss the dimensions of screws and how to determine the size of a screw. It is important to note that screw sizes can be large and small depending on the purpose.

The diameter of a screw is the diameter of its shaft, and it must match the inner diameter of its nuts and washers. Screws of a certain diameter are also called machine screws, and they can be larger or smaller. Screw diameters are measured on the shaft underneath the screw head. The American Society of Mechanical Engineers (ASME) standardized screw diameters in 3/50-inch to 16 (3/8-inch) inches, and more recently, sizes were added in U.S. fractions of an inch. While shaft and head diameters are standardized, screw length may vary from job to job.

In the case of the 2.3-mm screw group, the construct strength was not improved by the 1.2-mm group. The smaller screw size did not increase the strength of the construct. Further, ABS material did not improve the construct strength. Thus, the size of screw shaft is an important consideration in model design. And remember that the more complex your model is, the larger it will be. A screw of a given size will have a similar failure rate as a screw of a different diameter.

Although different screw sizes are widely used, the differences in screw size were not statistically significant. Although there are some limitations, screws of different sizes are generally sufficient for fixation of a metacarpal shaft fracture. However, further clinical studies are needed to compare screw sizes for fracture union rates. So, if you are unsure of what size of screw shaft you need for your case, make sure to check the metric chart and ensure you use the right one.

Material

The material of a screw shaft plays an important role in the overall performance of a screw. Axial and central forces act to apply torque to the screw, while external forces, such as friction, exert a bending moment. The torsional moments are reflected in the torque, and this causes the screw to rotate at a higher rate than necessary. To ensure the longevity of the screw, the material of the screw shaft should be able to handle the bending moment, while the diameter of the shaft should be small enough to avoid causing damage.

Screws are made from different metals, such as steel, brass, titanium, and bronze. Manufacturers often apply a top coating of chromium, brass, or zinc to improve corrosion resistance. Screws made of aluminum are not durable and are prone to rusting due to exposure to weather conditions. The majority of screw shafts are self-locking. They are suited for many applications, including threaded fasteners, C-clamps, and vises.

Screws that are fabricated with conical sections typically feature reduced open cross-sectional areas at the discharge point. This is a key design parameter of conical screw shafts. In fact, reductions of up to 72% are common across a variety of applications. If the screw is designed to have a hard-iron hanger bearing, it must be hardened. If the screw shaft is not hardened, it will require an additional lubricant.

Another consideration is the threads. Screw shafts are typically made of high-precision threads and ridges. These are manufactured on lathes and CNC machines. Different shapes require different materials. Materials for the screw shaft vary. There are many different sizes and shapes available, and each 1 has its own application. In addition to helical and conical screw shafts, different materials are also available. When choosing material, the best 1 depends on the application.

The life of the screw depends on its size, load, and design. In general, the material of the screw shaft, nut body, and balls and rollers determine its fatigue life. This affects the overall life of the screw. To determine whether a specific screw has a longer or shorter life, the manufacturer must consider these factors, as well as the application requirements. The material should be clean and free of imperfections. It should be smooth and free of cracks or flaking, which may result in premature failure.

Function

The function of a screw shaft is to facilitate the rotation of a screw. Screws have several thread forms, including single-start, double-start and multi-start. Each form has its own advantages and disadvantages. In this article we’ll explore each of them in detail. The function of a screw shaft can vary based on its design, but the following are common types. Here are some examples of screw shaft types and their purposes.

The screw’s torque enables it to lift objects. It can be used in conjunction with a bolt and nut to lift a load. Screws are also used to secure objects together. You can use them in screw presses, vises, and screw jacks. But their primary function is to hold objects together. Listed below are some of their main functions. When used to lift heavy loads, they can provide the required force to secure an object.

Screws can be classified into 2 types: square and round. Square threads are more efficient than round ones because they apply 0deg of angle to the nut. Square threads are also stronger than round threads and are often used in high-load applications. They’re generally cheaper to manufacture and are more difficult to break. And unlike square threads, which have a 0deg thread angle, these threads can’t be broken easily with a screwdriver.

A screw’s head is made of a series of spiral-like structures that extend from a cylindrical part to a tip. This portion of the screw is called the shank and is made of the smallest area. The shank is the portion that applies more force to the object. As the shaft extends from the head, it becomes thinner and narrow, forming a pointed tip. The head is the most important part of the screw, so it needs to be strong to perform its function.

The diameter of the screw shaft is measured in millimeters. The M8 screw has a thread pitch of 1.25 mm. Generally, the size of the screw shaft is indicated by the major and minor diameter. These dimensions are appended with a multiplication sign (M8x1).

Applications

The design of screws, including their size and shape, determines their critical rotating speeds. These speeds depend on the threaded part of the screw, the helix angle, and the geometry of the contact surfaces. When applied to a screw, these limits are referred to as “permissible speed limits.” These maximum speeds are meant for short periods of time and optimized running conditions. Continuous operation at these speeds can reduce the calculated life of a nut mechanism.

The main materials used to manufacture screws and screw shafts include steel, stainless steel, titanium, bronze, and brass. Screws may be coated for corrosion resistance, or they may be made of aluminium. Some materials can be threaded, including Teflon and nylon. Screw threads can even be molded into glass or porcelain. For the most part, steel and stainless steel are the most common materials for screw shafts. Depending on the purpose, a screw will be made of a material that is suitable for the application.

In addition to being used in fasteners, screw shafts are used in micrometers, drillers, conveyor belts, and helicopter blades. There are numerous applications of screw shafts, from weighing scales to measuring lengths. If you’re in the market for a screw, make sure to check out these applications. You’ll be happy you did! They can help you get the job done faster. So, don’t delay your next project.

If you’re interested in learning about screw sizing, then it’s important to know the axial and moment loads that your screws will experience. By following the laws of mechanics and knowing the load you can calculate the nominal life of your screw. You can also consider the effect of misalignment, uneven loading, and shocks on your screw. These will all affect the life of your screw. Then, you can select the right screw.