Product Description

Ball Screw with Nut details

Ball screw is made of screw, nut and ball. The function is to turn the rotary motion into liner motion, which is a further extension and development of ball screw. The significance of this development is to move into a rolling bearing from sliding action; With little friction, ball screws are widely used in various industrial equipment and precision instruments.

WHAT CAN WE SUPPLY?

-1.We have TBI or CHINAMFG sizes for your selection.

Our ball screws and nuts are the same sizes as TBI or CHINAMFG ,they can be interchanged with TBI or THK.

TBI sizes have enough inventory in stock.

THK sizes are produced on request.

-2.We are able to machine the 2 end sides of ball screws according to your requirements.

-3.We have full range of products what can be matched with ball screws.

We are able to match for you completely, including Machined Ball screw, Ball screw Nut, Nut housing/Nut Bracket, Shaft Coupler, End support unit.

-4.We provide many different series of ball screws and screw nuts, like SFU,SFK,SFS,SFI,SFY,SFA,DFU,DFI series and so on.

| SFU Ball Screw Nut Model No.(plastic deflector or metal deflector ) |

| SFU1204-3;SFU1605-3;SFU1605-4; SFU1610-2; SFU2005-3;SFU2005-4;SFU2505-3;SFU2505-4;SFU2510-4;SFU3205-3; SFU3205-4;SFU4005-4;SFU4571-4; SFU5571-4;SFU6310-4;SFU8571-4 |

| SFK Ball Screw Model No. |

| SFK0601;SFK0801;SFK0802;SFK082.5;SFK1002;SFK1004;SFK1202;SFK1402 |

| SFS Ball Screw Model No. |

| SFS1205;SFS1210;SFS1605;SFS1610;SFS1616;SFS1620;SFS2571;SFS2510;SFS2525;SFS3210;SFS4571 |

| SFI Ball Screw Model No. |

| SFI1605;SFI1610;SFI2005;SFI2505;SFI2510;SFI3205;SFI3210;SFI4005;SFI4571 |

| SFE Ball Screw Model No. |

| SFE1616;SFE2571;SFE2525;SFE3232;SFE4040 |

| SFY Ball Screw Model No. |

| SFY1616;SFY2571;SFY2525;SFY3232;SFY4040 |

| SFA Ball Screw Model No. |

| SFA1610;SFA1620;SFA2571;SFA2510;SFA2525 |

| Ball Screw End Supports Model No. |

| BK10 BF10, BK12 BF12, BK15 BF15, BK17 BF17, BK20 BF20, BK25 BF25,BK30 BF30, BK35 BF35, BK40 BF40 |

| EK06 EF06, EK08 EF08, EK10 EF10, EK12 EF12, EK15 EF15, EK20 EF20; EK25 EF25 |

| FK06 FF6, FK08 FF08,FK10 FF10, FK12 FF12, FK15 FF15, FK20 FF20, FK25 FF25, FK30 FF30 |

| Ball Screw Nut Housings Model No. (Aluminium or Iron) |

| DSG12H(1204),DSG16H(1605/1610), DSG20H(2005/2571), DSG25H(2505/2510), DSG32H(3205/3210), DSG40H(4005/4571),DSG50H(5005/5571) |

Each series has its own characteristics. The following table list the differences in appearance and characteristics for your reference.

Rolled Ball Screw Application:

1. Engraving machines; 2. High speed CNC machinery;

4. Auto-machinery. 3. Semi-Conductor equipment;

5. Machine tools; 6. Industrial Machinery;

7. Printing machine; 8. Paper-processing machine;

9. Textiles machine; 10. Electronic machinery;

11. Transport machinery; 12. Robot etc.

Rolled ball screws can not only be used in above general machinery, but also in many advanced industries. Rolled ball screw with a motor assembles electrical-mechanical actuator, which is more eco-friendly than hydraulic pump system. Nowadays it’s applied to electric vehicles, solar power plants, railway devices and many medical and leisure equipments.

Kindly pls contact me if you have any question!!!!!!!!!!!!!!!!!!!!!! /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Screw Diameter: | 31-40mm |

| Flange: | Without Flange |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you select the right worm screw for a specific application?

Selecting the right worm screw for a specific application involves considering several factors to ensure optimal performance and compatibility. Here are the key steps to guide you in selecting the appropriate worm screw:

- Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as torque, speed, direction of rotation, load capacity, precision, and environmental conditions. Determine the desired gear ratio and any additional features or specifications needed for the worm screw to meet the application’s objectives.

- Consider Design Parameters: Evaluate the design parameters of the worm screw, including the number of starts, lead angle, pitch diameter, and thread profile. These parameters directly influence the gear ratio, mechanical efficiency, and load-carrying capacity of the worm screw. Choose the design parameters that align with the application requirements, considering factors like torque transmission, speed regulation, and size constraints.

- Material Selection: Selecting the right material for the worm screw is crucial for its durability and performance. Consider factors such as strength, wear resistance, and compatibility with other mating components. Common materials for worm screws include hardened steel, stainless steel, bronze, or other alloys. Consult material specifications and consider the anticipated operating conditions to ensure the selected material can withstand the loads and environmental factors present in the application.

- Lubrication Requirements: Determine the lubrication requirements for the specific application. Some worm screws may require lubrication to reduce friction and wear, while others may have self-lubricating properties. Consider the type of lubricant (oil or grease), the frequency of lubrication, and the accessibility for lubrication maintenance. Ensure that the selected worm screw is compatible with the required lubrication method and can meet the lubrication demands of the application.

- Consider Mounting and Installation: Evaluate the mounting and installation requirements of the worm screw. Assess factors such as space limitations, alignment considerations, coupling options, and connection methods. Ensure that the selected worm screw can be easily integrated into the mechanical system and meets the specific installation requirements without compromising overall performance.

- Consult Manufacturer Resources: Utilize manufacturer resources, such as catalogs, technical specifications, and application guidelines, to gather information about available worm screw options. Manufacturers often provide recommendations and selection guides based on different application scenarios and performance criteria. Their expertise can help ensure that you choose the most suitable worm screw for your specific application.

- Review Cost and Availability: Consider the cost and availability of the worm screw. Evaluate the pricing, lead times, and availability from different suppliers or manufacturers. Balance the desired performance and quality with the budget constraints of the project, ensuring that the selected worm screw offers a cost-effective solution without compromising reliability or performance.

By following these steps and considering the application requirements, design parameters, material selection, lubrication needs, mounting considerations, manufacturer resources, and cost factors, you can select the right worm screw that meets the specific demands of your application. It’s important to consult with experts or seek assistance from manufacturers if you require further guidance or have unique requirements.

Are there different types of worm screws available?

Yes, there are different types of worm screws available to suit various applications and requirements. The design and characteristics of a worm screw can vary based on factors such as the material used, the thread geometry, the type of worm wheel, and the intended application. Here are some common types of worm screws:

- Standard Worm Screws: Standard worm screws are the most commonly used type and are available in a wide range of sizes and materials. They typically have a single-start thread and are made from materials such as steel, stainless steel, or bronze. Standard worm screws are suitable for general-purpose applications where moderate precision and load capacity are required.

- Double-Enveloping Worm Screws: Double-enveloping worm screws, also known as hourglass worm screws, have a unique thread profile that improves contact and load distribution between the worm screw and the worm wheel. This design offers enhanced torque transmission, higher efficiency, and increased load-carrying capacity compared to standard worm screws. Double-enveloping worm screws are often used in heavy-duty applications, such as gearboxes and high-load power transmission systems.

- Low-Lead Worm Screws: Low-lead worm screws have a smaller thread lead angle compared to standard worm screws. This design reduces the amount of sliding contact between the threads of the worm screw and the teeth of the worm wheel, resulting in lower friction and improved efficiency. Low-lead worm screws are commonly used in applications where high efficiency and reduced heat generation are critical, such as in precision machinery and high-speed gear systems.

- Self-Locking Worm Screws: Self-locking worm screws are designed to have a high friction angle between the threads, making them capable of preventing reverse motion or backdriving. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices in certain applications. Self-locking worm screws are commonly used in vertical lift systems, hoists, and other applications where holding the load position is essential.

- High-Precision Worm Screws: High-precision worm screws are manufactured to tighter tolerances and have improved accuracy compared to standard worm screws. They are designed to provide precise positioning and motion control in applications where high accuracy and repeatability are required. High-precision worm screws are often used in CNC machines, robotics, and other precision equipment.

- Customized Worm Screws: In addition to the standard types mentioned above, worm screws can also be customized to meet specific application requirements. Customized worm screws may involve variations in thread geometry, pitch, diameter, materials, or other parameters to suit unique applications or performance specifications.

The selection of the appropriate type of worm screw depends on factors such as the desired load capacity, efficiency requirements, backlash tolerance, positional accuracy, and environmental conditions. It is important to consult with manufacturers, engineers, or experts familiar with worm screw applications to determine the most suitable type for a specific application.

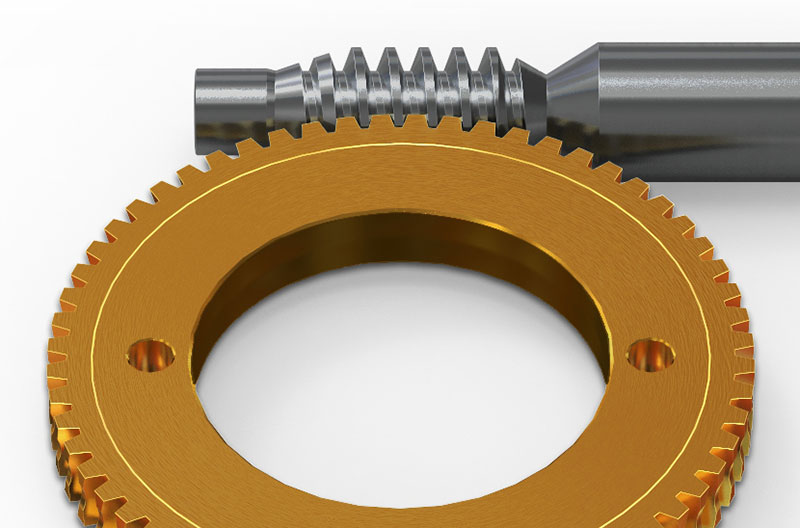

What is a worm screw in mechanical engineering?

In mechanical engineering, a worm screw, also known as a worm gear screw or worm gear, is a type of gear mechanism used to transmit motion and power between non-parallel shafts. It consists of a spiral-shaped screw, called the worm, and a gear wheel, called the worm wheel or worm gear. The worm screw and worm wheel have helical teeth that mesh together to transfer rotational motion.

The worm screw typically has a single thread or multiple threads wrapped around its cylindrical body. The worm wheel, on the other hand, has teeth that are specially shaped to mesh with the worm screw. The orientation of the worm screw and worm wheel is such that the axes of rotation are perpendicular to each other. This configuration allows the worm screw to convert rotational motion along its axis into rotary motion perpendicular to its axis.

One of the defining characteristics of a worm screw is its high gear ratio. Due to the helical nature of the teeth, a worm screw can achieve a high reduction ratio in a single gear stage. This means that a small rotation of the worm screw can result in a substantial rotation of the worm wheel. The ratio of the number of teeth on the worm wheel to the number of threads on the worm screw determines the reduction ratio.

Worm screws have several advantages and applications in mechanical engineering:

- High Reduction Ratio: As mentioned earlier, worm screws offer high gear ratios, making them suitable for applications that require significant speed reduction and torque multiplication. They are commonly used in applications where large gear reductions are needed, such as in conveyor systems, winches, and lifting equipment.

- Self-Locking: A unique characteristic of worm screws is their self-locking property. The angle of the helical teeth creates a wedging effect that prevents the worm wheel from driving the worm screw. This self-locking feature allows worm screws to hold loads without the need for additional braking mechanisms, making them suitable for applications where holding positions or preventing back-driving is crucial, such as in elevators or lifting mechanisms.

- Smooth and Quiet Operation: The helical teeth of the worm screw and worm wheel facilitate smooth and quiet operation. The gradual engagement and disengagement of the teeth minimize noise, vibration, and backlash, resulting in a more efficient and reliable gear mechanism.

- Compact Design: Worm screws offer a compact design compared to other gear mechanisms. The perpendicular arrangement of the worm screw and worm wheel allows for a compact and space-saving installation, making them suitable for applications where size constraints are a consideration.

- Reduction of Input Speed: Worm screws are commonly used to reduce the speed of the input shaft while increasing torque. This is advantageous in applications where slower, controlled motion is required, such as in industrial machinery, conveyors, and robotics.

It should be noted that worm screws also have some limitations, including lower efficiency compared to other gear mechanisms, higher friction due to sliding motion, and limited reverse operation capabilities. Therefore, careful consideration of the specific application requirements is necessary when deciding whether to use a worm screw in a mechanical system.

editor by Dream 2024-05-16

China best Custom Made Plastic Screw Rod with Bearing near me manufacturer

Product Description

Custom made plastic screw rod with bearing

Description:

Nylon PA6 Sheets & Rods that made the with 100% Virgin Raw Material by HangZhou Engineering Plastics Industries (Group) Company, has the best performance, such as: very tough, even at low temperatures, and high hardness in the surface, toughness, mechanical lower shock, and abrasion resistance. Combined with these characteristics and good insulation, and chemical properties, it has become common-level materials. Its widely used in a variety of mechanical structures and spare parts. Nylon PA6 products that made by HangZhou Engineering Plastics Industries (Group) Company, has the higher hardness, rigidity, a good resistance to wear and heat deflection temperature.

Advantages:

1. Good Tensile strength;

2. High impact and notching impact strength;

3. High heat deflection temperature ;

4. High strength and stiffness;

5. Good glide and limp home characters;

6. Good chemical stability against organic solvents and fuels;

7. Resistant to thermal aging (applicable temperature between -50°C and 110°C;

8. Size alternation by humidity absorption must be considered;

Application:

1. Nylon PA6 Products that made by HangZhou Engineering Plastics Industries (Group) Company is widely substituted for wear parts of mechanical equipment, or used as quick-wear parts of equipment instead of copper and alloy;

2. Shaft sleeve, bearing bush, lining, CZPT plate, gear;

3. Worm gear, roller copper CZPT rail, piston ring, seal ring, slide block;

4. Spheric bowl, impeller, blade, cam, nut, valve plate,

5. Pipe, stuffing box, rack, belt pulley, pump rotor, etc.

Main Properties of MC Nylon

| Property | Item No. | Unit | MC Nylon (Natural) | Oil Nylon+Carbon (Black) | Oil Nylon (Green) | MC901 (Blue) | MC Nylon+MSO2 (Light black) |

|

| Mechanical Properties | 1 | Density | g/cm3 | 1.15 | 1.15 | 1.135 | 1.15 | 1.16 |

| 2 | Water absorption (23ºC in air) | % | 1.8-2.0 | 1.8-2.0 | 2 | 2.3 | 2.4 | |

| 3 | Tensile strength | MPa | 89 | 75.3 | 70 | 81 | 78 | |

| 4 | Tensile strain at break | % | 29 | 22.7 | 25 | 35 | 25 | |

| 5 | Compressive stress(at 2%nominal strain) | MPa | 51 | 51 | 43 | 47 | 49 | |

| 6 | Charpy impact strength (unnotched) | KJ/m2 | No break | No break | ≥50 | No BK | No break | |

| 7 | Charpy impact strength (notched) | KJ/m2 | ≥5.7 | ≥6.4 | 4 | 3.5 | 3.5 | |

| 8 | Tensile modulus of elasticity | MPa | 3190 | 3130 | 3000 | 3200 | 3300 | |

| 9 | Ball indentation hardness | N/mm2 | 164 | 150 | 145 | 160 | 160 | |

| 10 | Rockwell hardness | – | M88 | M87 | M82 | |||

The Four Basic Components of a Screw Shaft

There are 4 basic components of a screw shaft: the Head, the Thread angle, and the Threaded shank. These components determine the length, shape, and quality of a screw. Understanding how these components work together can make purchasing screws easier. This article will cover these important factors and more. Once you know these, you can select the right type of screw for your project. If you need help choosing the correct type of screw, contact a qualified screw dealer.

Thread angle

The angle of a thread on a screw shaft is the difference between the 2 sides of the thread. Threads that are unified have a 60 degree angle. Screws have 2 parts: a major diameter, also known as the screw’s outside diameter, and a minor diameter, or the screw’s root diameter. A screw or nut has a major diameter and a minor diameter. Each has its own angle, but they all have 1 thing in common – the angle of thread is measured perpendicularly to the screw’s axis.

The pitch of a screw depends on the helix angle of the thread. In a single-start screw, the lead is equal to the pitch, and the thread angle of a multiple-start screw is based on the number of starts. Alternatively, you can use a square-threaded screw. Its square thread minimizes the contact surface between the nut and the screw, which improves efficiency and performance. A square thread requires fewer motors to transfer the same load, making it a good choice for heavy-duty applications.

A screw thread has 4 components. First, there is the pitch. This is the distance between the top and bottom surface of a nut. This is the distance the thread travels in a full revolution of the screw. Next, there is the pitch surface, which is the imaginary cylinder formed by the average of the crest and root height of each tooth. Next, there is the pitch angle, which is the angle between the pitch surface and the gear axis.

Head

There are 3 types of head for screws: flat, round, and hexagonal. They are used in industrial applications and have a flat outer face and a conical interior. Some varieties have a tamper-resistant pin in the head. These are usually used in the fabrication of bicycle parts. Some are lightweight, and can be easily carried from 1 place to another. This article will explain what each type of head is used for, and how to choose the right 1 for your screw.

The major diameter is the largest diameter of the thread. This is the distance between the crest and the root of the thread. The minor diameter is the smaller diameter and is the distance between the major and minor diameters. The minor diameter is half the major diameter. The major diameter is the upper surface of the thread. The minor diameter corresponds to the lower extreme of the thread. The thread angle is proportional to the distance between the major and minor diameters.

Lead screws are a more affordable option. They are easier to manufacture and less expensive than ball screws. They are also more efficient in vertical applications and low-speed operations. Some types of lead screws are also self-locking, and have a high coefficient of friction. Lead screws also have fewer parts. These types of screw shafts are available in various sizes and shapes. If you’re wondering which type of head of screw shaft to buy, this article is for you.

Threaded shank

Wood screws are made up of 2 parts: the head and the shank. The shank is not threaded all the way up. It is only partially threaded and contains the drive. This makes them less likely to overheat. Heads on wood screws include Oval, Round, Hex, Modified Truss, and Flat. Some of these are considered the “top” of the screw.

Screws come in many sizes and thread pitches. An M8 screw has a 1.25-mm thread pitch. The pitch indicates the distance between 2 identical threads. A pitch of 1 is greater than the other. The other is smaller and coarse. In most cases, the pitch of a screw is indicated by the letter M followed by the diameter in millimetres. Unless otherwise stated, the pitch of a screw is greater than its diameter.

Generally, the shank diameter is smaller than the head diameter. A nut with a drilled shank is commonly used. Moreover, a cotter pin nut is similar to a castle nut. Internal threads are usually created using a special tap for very hard metals. This tap must be followed by a regular tap. Slotted machine screws are usually sold packaged with nuts. Lastly, studs are often used in automotive and machine applications.

In general, screws with a metric thread are more difficult to install and remove. Fortunately, there are many different types of screw threads, which make replacing screws a breeze. In addition to these different sizes, many of these screws have safety wire holes to keep them from falling. These are just some of the differences between threaded screw and non-threaded. There are many different types of screw threads, and choosing the right 1 will depend on your needs and your budget.

Point

There are 3 types of screw heads with points: cone, oval, and half-dog. Each point is designed for a particular application, which determines its shape and tip. For screw applications, cone, oval, and half-dog points are common. Full dog points are not common, and they are available in a limited number of sizes and lengths. According to ASTM standards, point penetration contributes as much as 15% of the total holding power of the screw, but a cone-shaped point may be more preferred in some circumstances.

There are several types of set screws, each with its own advantage. Flat-head screws reduce indentation and frequent adjustment. Dog-point screws help maintain a secure grip by securing the collar to the screw shaft. Cup-point set screws, on the other hand, provide a slip-resistant connection. The diameter of a cup-point screw is usually half of its shaft diameter. If the screw is too small, it may slack and cause the screw collar to slip.

The UNF series has a larger area for tensile stress than coarse threads and is less prone to stripping. It’s used for external threads, limited engagement, and thinner walls. When using a UNF, always use a standard tap before a specialized tap. For example, a screw with a UNF point is the same size as a type C screw but with a shorter length.

Spacer

A spacer is an insulating material that sits between 2 parts and centers the shaft of a screw or other fastener. Spacers come in different sizes and shapes. Some of them are made of Teflon, which is thin and has a low coefficient of friction. Other materials used for spacers include steel, which is durable and works well in many applications. Plastic spacers are available in various thicknesses, ranging from 4.6 to 8 mm. They’re suitable for mounting gears and other items that require less contact surface.

These devices are used for precision fastening applications and are essential fastener accessories. They create clearance gaps between the 2 joined surfaces or components and enable the screw or bolt to be torqued correctly. Here’s a quick guide to help you choose the right spacer for the job. There are many different spacers available, and you should never be without one. All you need is a little research and common sense. And once you’re satisfied with your purchase, you can make a more informed decision.

A spacer is a component that allows the components to be spaced appropriately along a screw shaft. This tool is used to keep space between 2 objects, such as the spinning wheel and an adjacent metal structure. It also helps ensure that a competition game piece doesn’t rub against an adjacent metal structure. In addition to its common use, spacers can be used in many different situations. The next time you need a spacer, remember to check that the hole in your screw is threaded.

Nut

A nut is a simple device used to secure a screw shaft. The nut is fixed on each end of the screw shaft and rotates along its length. The nut is rotated by a motor, usually a stepper motor, which uses beam coupling to accommodate misalignments in the high-speed movement of the screw. Nuts are used to secure screw shafts to machined parts, and also to mount bearings on adapter sleeves and withdrawal sleeves.

There are several types of nut for screw shafts. Some have radial anti-backlash properties, which prevent unwanted radial clearances. In addition, they are designed to compensate for thread wear. Several nut styles are available, including anti-backlash radial nuts, which have a spring that pushes down on the nut’s flexible fingers. Axial anti-backlash nuts also provide thread-locking properties.

To install a ball nut, you must first align the tangs of the ball and nut. Then, you must place the adjusting nut on the shaft and tighten it against the spacer and spring washer. Then, you need to lubricate the threads, the ball grooves, and the spring washers. Once you’ve installed the nut, you can now install the ball screw assembly.

A nut for screw shaft can be made with either a ball or a socket. These types differ from hex nuts in that they don’t need end support bearings, and are rigidly mounted at the ends. These screws can also have internal cooling mechanisms to improve rigidity. In this way, they are easier to tension than rotating screws. You can also buy hollow stationary screws for rotator nut assemblies. This type is great for applications requiring high heat and wide temperature changes, but you should be sure to follow the manufacturer’s instructions.

China manufacturer TOQ000060 Factory direct sales Drive shaft center support bearing Drive shaft hanger Drive shaft support bearings with Good quality

Model: HILUX VII Pickup (_N1_, _N2_, Lf205j Style Of Agricultural Gearbox, Transmission Gearbox Tractor PTO Gear Box For Rotary Tiller Harvester Electrical power Harrow Mixer _N3_)

12 months: 2004-

OE NO.: TOQ000060

Car Fitment: Toyota

Reference NO.: MD-1065, TCB-571

Size: 23*17.5*6.5, for European Japanese American Korean Propshaft Prop Shaft Propeller Shaft above three hundred+ items Kowa brand name factory value 23*17.5*6.five

Materials: Rubber Metallic Compliant, Generate shaft centre support/travel shaft hanger

Model Quantity: TOQ000060

Guarantee: 3 Months

Vehicle Make: for CZPT collection

Item name: Hydraulic Hose High Pressure Rubber Hose

Color: Personalized Color

Application: vehicle

Attribute: Tough

Sort: Generate shaft centre

Usage: Rubber Metallic Compliant

dimensions CM: 23*17.5*6.five

N.G(g): 750

Packaging Details: 1. neutral packing bag2.making the packing in accordance to customer’s necessity

Port: ZheJiang port and other individuals

Item ItemDrive shaft middle help/drive shaft hangerMaterialRubber Metallic CompliantN.G(g)750size CM23*17.5*6.5ColorBlack, cabin petrol bajaj automobile rickshaw in india Blue, Pink or to Be CustomizedApplicationCar FeaturesCan bear Substantial temperature and High Strain More Productions Firm Profile Certifications Products Line Packaging& R collection foot-mounted helical equipment units with strong shaft helical bevel gearboxes Shipping and delivery FAQ

How to explain to if your driveshaft wants changing

What is the trigger of the unbalanced generate shaft? Unstable U-joint? Your auto may make clicking noises even though driving. If you can listen to it from both sides, it may possibly be time to hand it over to the mechanic. If you happen to be not positive, read on to find out more. The good news is, there are numerous ways to notify if your driveshaft requirements changing.

unbalanced

An unbalanced driveshaft can be the resource of odd noises and vibrations in your automobile. To resolve this issue, you should get in touch with a specialist. You can try a amount of issues to correct it, which includes welding and modifying the weight. The adhering to are the most frequent strategies. In addition to the methods over, you can use standardized weights to harmony the driveshaft. These standardized weights are connected to the shaft by welders.

An unbalanced generate shaft generally generates lateral vibrations for each revolution. This sort of vibration is generally caused by a destroyed shaft, missing counterweights, or a foreign item stuck on the travel shaft. On the other hand, torsional vibrations happen 2 times per revolution, and they are triggered by shaft period shifts. Ultimately, essential velocity vibration takes place when the RPM of the travel shaft exceeds its rated capability. If you suspect a driveshaft dilemma, verify the following:

Manually modifying the imbalance of a drive shaft is not the least difficult task. To steer clear of the problems of handbook balancing, you can choose to use standardized weights. These weights are fixed on the outer circumference of the travel shaft. The operator can manually place the bodyweight on the shaft with special resources, or use a robotic. However, guide balancers have several down sides.

unstable

When the angular velocity of the output shaft is not continual, it is unstable. The angular velocity of the output shaft is .004 at ph = 29.5 and 1.9 at t = 1.9. The angular velocity of the intermediate shaft is not a dilemma. But when it is unstable, the torque utilized to it is as well a lot for the equipment. It may possibly be a good thought to examine the pressure on the shaft.

An unstable push shaft can cause a good deal of sounds and mechanical vibration. It can guide to untimely shaft tiredness failure. CZPT studies the effect of shaft vibration on the rotor bearing technique. They investigated the effect of flex coupling misalignment on the vibration of the rotor bearing method. They assume that the vibrational reaction has two components: x and y. Even so, this approach has restricted application in several situations.

Experimental benefits demonstrate that the presence of cracks in the output shaft may mask the unbalanced excitation traits. For case in point, the presence of superharmonic peaks on the spectrum is attribute of cracks. The existence of cracks in the output shaft masks unbalanced excitation characteristics that cannot be detected in the transient response of the enter shaft. Figure 8 demonstrates that the frequency of the rotor will increase at vital velocity and decreases as the shaft passes the normal frequency.

Unreliable

If you’re having difficulties driving your auto, odds are you have operate into an unreliable driveshaft. This kind of drivetrain can cause the wheels to stick or not flip at all, and also limit the overall handle of the vehicle. Whatever the purpose, these problems ought to be settled as quickly as feasible. Right here are some symptoms to search for when diagnosing a driveshaft fault. Let’s just take a closer seem.

The 1st symptom you could recognize is an unreliable push shaft. You may possibly feel vibrations, or listen to noises beneath the car. Relying on the cause, it could be a broken joint or a damaged shaft. The excellent information is that driveshaft repairs are usually reasonably inexpensive and get less time than a complete drivetrain alternative. If you are not positive what to do, CZPT has a manual to replacing the U-connector.

One of the most typical indications of an unreliable driveshaft is clanging and vibration. These seems can be caused by worn bushings, unfastened U-joints, or broken heart bearings. This can cause extreme vibration and noise. You can also come to feel these vibrations through the steering wheel or the ground. An unreliable driveshaft is a symptom of a greater dilemma.

Unreliable U-joints

A automobile with an unreliable U-joint on the generate shaft can be harmful. A negative u-joint can stop the motor vehicle from driving correctly and may even trigger you problems. Unreliable u-joints are inexpensive to change and you must try receiving components from good quality companies. Unreliable U-joints can trigger the vehicle to vibrate in the chassis or gear lever. This is a confident signal that your vehicle has been neglected in routine maintenance.

Replacing a U-joint is not a challenging task, but it calls for specific tools and a good deal of elbow grease. If you will not have the right tools, or you’re unfamiliar with mechanical terminology, it’s greatest to look for the support of a mechanic. A skilled mechanic will be capable to correctly evaluate the dilemma and propose an proper answer. But if you will not come to feel self-confident enough, you can change your possess U-connector by following a handful of basic methods.

To make sure the vehicle’s driveshaft is not ruined, check the U-joint for put on and lubrication. If the U-joint is worn, the steel parts are likely to rub from each and every other, creating wear. The quicker a problem is diagnosed, the quicker it can be fixed. Also, the longer you wait around, the much more you shed on repairs.

damaged drive shaft

The driveshaft is the part of the vehicle that connects the wheels. If the driveshaft is ruined, the wheels may possibly quit turning and the car may possibly slow down or quit transferring fully. It bears the excess weight of the auto by itself as effectively as the load on the highway. So even a slight bend or break in the drive shaft can have dire effects. Even a piece of unfastened metallic can turn out to be a deadly missile if dropped from a motor vehicle.

If you hear a screeching noise or growl from your vehicle when shifting gears, your driveshaft might be broken. When this occurs, harm to the u-joint and too much slack in the push shaft can result. These problems can more harm the drivetrain, like the front half. You ought to substitute the driveshaft as shortly as you discover any indicators. Following replacing the driveshaft, you can start looking for indicators of use.

A knocking sound is a indication of harm to the drive shaft. If you hear this seem even though driving, it may possibly be because of to worn couplings, broken propshaft bearings, or broken U-joints. In some situations, the knocking noise can even be induced by a ruined U-joint. When this takes place, you might require to exchange the entire driveshaft, requiring a new 1.

Servicing charges

The cost of fixing a driveshaft varies widely, based on the type and lead to of the difficulty. A new driveshaft fees among $300 and $1,300, including labor. Repairing a broken driveshaft can cost everywhere from $200 to $three hundred, based on the time needed and the type of parts necessary. Indicators of a damaged driveshaft contain unresponsiveness, vibration, chassis sounds and a stationary automobile.

The very first point to contemplate when estimating the expense of fixing a driveshaft is the type of motor vehicle you have. Some autos have more than one particular, and the parts employed to make them could not be suitable with other autos. Even if the same vehicle has two driveshafts, the destroyed ones will expense a lot more. Thankfully, several auto mend stores supply free prices to repair damaged driveshafts, but be conscious that these kinds of operate can be difficult and high-priced.

China Professional Cardan Supports 37230-26010 Center support bearing Drive shaft support From Manufacturer with Good quality

OE NO.: 37230-26571, 37230-26571

Dimensions: 30mm

Material: Steel+Rubber, Steel+Rubber

Model Number: 37230-26571

Warranty: 6 Months

Vehicle Make: for TOYOTA

Variety: Driveshaft

Certification: ISO9001:2008

Sample: Avaliable

Packing: Customers’ Requirement

Inner Diameter: 30mm

Packaging Particulars: Neutral packing or personalized packing for heart support bearing.

Port: ZheJiang or HangZhou

1. We give:

1. 2 years limited warranty for Rubber

two. 16000 kilometers for Bearing

37230-26571 is installed at the bottom center of vehicle, 26208628043 Automated Transmission Front Push Shafts For BMW 528i 535i 550i 650i 750i 750iL X Travel and utilized to support the driving shaft, it is composed of bearing, bracket, Processing nylon synchronous pulley MXL XL L H XH plastic timing pulley POM equipment For Cranes Heavy Machinery rubber cushion and flingers and so forth., the great sealing performance of bearing can make certain lengthy working daily life.

Merchandise Number

37230-26571

Bearing ID (A)

30mm

Mounting Width (C)

Centre Line Top (B)

Comment

Like 2 flingers

Application

for TOYOTA

two.Our Parts for center help bearing

three.About Us

four. Neutral packing & Colour box with HZZN Model

middle assist bearing, DROPSHIPPING Hot SALE 360 Degree Rotation Ball Casters 4pcs Paste Variety Universal Pulley center bearing, push shaft support

5. Our Exhibition

2017,To be continued….

In order to offer you you the best provider, Excellent 479Q vehicle transmission gearbox for Geely PHangZhou make sure you kindly give us the following information:

1. Vehicle Model 2. OEM areas variety 3. Buy amount 4. Anticipating shipping time

If you didn’t find the goods you want, we can manufacture according to your sample or requirements and designs.

For more data, welcome to speak to us.

What is a driveshaft and how much does it expense to substitute a single?

Your car is manufactured up of numerous transferring components. Being aware of each element is important due to the fact a broken driveshaft can seriously injury other elements of the car. You might not know how crucial your driveshaft is, but it’s important to know if you want to fix your auto. In this article, we will examine what a driveshaft is, what its indicators are, and how much it expenses to change a driveshaft.

Fix destroyed driveshafts

A broken driveshaft does not allow you to switch the wheels freely. It also exposes your car to increased mend costs thanks to damaged driveshafts. If the drive shaft breaks whilst the vehicle is in motion, it might result in a crash. Also, it can drastically affect the performance of the automobile. If you don’t fix the problem correct away, you could risk far more expensive repairs. If you suspect that the generate shaft is destroyed, do the pursuing.

1st, make certain the generate shaft is secured from dust, moisture, and dust. A suitable driveshaft include will prevent grease from accumulating in the driveshaft, decreasing the likelihood of additional hurt. The grease will also cushion the steel-to-metal speak to in the constant velocity joints. For case in point, hitting a comfortable substance is greater than hitting a steel wall. A broken prop shaft can not only trigger difficult cornering, but it can also trigger the vehicle to vibrate, which can more damage the rest of the drivetrain.

If the driveshaft is damaged, you can decide on to correct it oneself or just take it to a mechanic. Generally, driveshaft repairs cost close to $two hundred to $300. Elements and labor may fluctuate primarily based on your car type and variety of fix. These components can expense up to $600. However, if you will not have a mechanical history, it is greater to go away it to a specialist.

If you discover that one of the two generate shafts is worn, it truly is time to repair it. Worn bushings and bearings can trigger the push shaft to vibrate unnecessarily, triggering it to split and trigger additional damage. You can also check the middle bearing if there is any enjoy in the bearing. If these signs and symptoms happen, it is very best to just take your car to a mechanic as quickly as attainable.

Discover about U-joints

While most automobiles have at the very least 1 sort of U-joint, there are other types offered. CV joints (also recognized as hot rod joints) are utilized in a assortment of purposes. The minimal axis is shorter than the main axis on which the U-joint is situated. In the two cases, the U-joints are lubricated at the manufacturing facility. For the duration of servicing, the drive shaft slip joint must be lubricated.

There are two main variations of U-joints, which includes forged and push match. They are generally held in spot by C-clamps. Some of these U-joints have knurls or grooves. When choosing the proper fitting, be sure to evaluate the complete fitting. To make confident you get the correct measurement, you can use the dimension chart or check the handbook for your specific design.

In addition to lubrication, the condition of the U-joint ought to be checked frequently. Lubricate them regularly to keep away from untimely failure. If you hear a clicking seem when shifting gears, the u-joint place may possibly be misaligned. In this circumstance, the bearing might want to be serviced. If there is inadequate grease in the bearings, the universal joint might need to be replaced.

U-joint is an critical component of the auto transmission shaft. With out them, your car would have no wheeled suspension. With out them, your automobile will have a rickety front end and a wobbly rear end. Simply because vehicles can’t push on ultra-flat surfaces, they need to have flexible driveshafts. The U-joint compensates for this by making it possible for it to move up and down with the suspension.

A proper inspection will decide if your u-joints are unfastened or worn. It need to be straightforward to pull them out. Make positive not to pull them all the way out. Also, the bearing caps should not go. Any indicators of roughness or put on would reveal a need to have for a new UJ. Also, it is important to notice that worn UJs cannot be fixed.

Symptoms of Driveshaft Failure

A single of the most common issues associated with a defective driveshaft is difficulty turning the wheels. This seriously restrictions your all round manage over the car. Thankfully, there are a number of signs that could indicate that your driveshaft is failing. You must take fast actions to decide the cause of the dilemma. 1 of the most typical triggers of driveshaft failure is a weak or faulty reverse gear. Other widespread brings about of driveshaft harm include driving too hard, obtaining stuck in reverse equipment and differential lock.

An additional indicator of a unsuccessful driveshaft is uncommon noise even though driving. These noises are typically the outcome of wear on the bushings and bearings that help the push shaft. They can also lead to your car to screech or scratch when switching from drive to idle. Based on the speed, the sound may be accompanied by vibration. When this takes place, it truly is time to ship your motor vehicle in for a driveshaft replacement.

1 of the most widespread symptoms of driveshaft failure is visible jitter when accelerating. This could be a sign of a free U-joint or worn center bearing. You ought to thoroughly inspect your car to decide the trigger of these appears and corresponding symptoms. A accredited mechanic can support you determine the cause of the noise. A damaged propshaft can severely limit the drivability of the car.

Typical inspection of the travel shaft can avert significant hurt. Dependent on the harm, you can substitute the driveshaft for wherever from $500 to $1,000. Depending on the severity of the harm and the degree of repair, the expense will depend on the amount of elements that need to have to be changed. Do not drive with a negative driveshaft as it can trigger a critical crash. There are numerous methods to stay away from this dilemma totally.

The very first symptom to appear for is a worn U-joint. If the U-joint will come free or moves also considerably when making an attempt to flip the steering wheel, the driveshaft is defective. If you see noticeable rust on the bearing cap seals, you can just take your auto to a mechanic for a comprehensive inspection. A worn u-joint can also reveal a problem with the transmission.

The value of replacing the travel shaft

Depending on your point out and provider centre, a driveshaft fix can price as minor as $300 or as higher as $2,000, based on the details of your vehicle. Labor expenses are usually around $70. Prices for the parts by themselves range from $400 to $600. Labor costs also vary by model and vehicle make. Ultimately, the choice to mend or exchange the driveshaft will rely on whether you need to have a fast car mend or a total automobile mend.

Some automobiles have two independent driveshafts. 1 goes to the entrance and the other goes to the again. If your auto has four wheel travel, you will have two. If you happen to be changing the axles of an all-wheel-push car, you’ll require a unique part for every axle. Picking the mistaken 1 can outcome in much more high-priced repairs. Prior to you begin shopping, you need to know exactly how much it will price.

Depending on the type of automobile you personal, a driveshaft substitute will value between PS250 and PS500. Luxury vehicles can price as significantly as PS400. Even so, for safety and the overall functionality of the auto, replacing the driveshaft may possibly be a needed mend. The cost of changing a driveshaft depends on how long your car has been on the highway and how a lot dress in and tear it has knowledgeable. There are some indicators that indicate a faulty drive shaft and you should take instant motion.

Repairs can be high-priced, so it truly is best to hire a mechanic with experience in the field. You are going to be spending hundreds of bucks a thirty day period, but you may have peace of mind realizing the occupation will be completed proper. Keep in mind that you could want to question a buddy or family member to aid you. Dependent on the make and design of your vehicle, changing the driveshaft is more expensive than replacing the areas and carrying out it oneself.

If you suspect that your travel shaft is destroyed, be confident to repair it as shortly as feasible. It is not a good idea to travel a automobile with irregular vibration and sound for a extended time. The good news is, there are some fast techniques to correct the problem and steer clear of high priced repairs later on. If you’ve got seen the indicators over, it’s worth acquiring the task completed. There are a lot of indications that your driveshaft might need services, like deficiency of electricity or difficulty moving the motor vehicle.

China manufacturer 37230-24010 China factory drive shaft center support bearing with Great quality

OE NO.: 37230-24571

Dimension: OEM

Substance: Metal+rubber

Product Number: 37230-24571

Guarantee: 6 Months

Automobile Make: Toyato

Merchandise Title: Heart bearing

Application: Toyato

Shade: Black, pink, blue, purple, Arm bushing for CZPT hilux automotive shock absorber bushing inexperienced, and so on.

Packing: Neutral Packing

Shipping and delivery time: thirty Times

Top quality: Substantial-Good quality

Edge: Long Toughness

Position: Front Left Appropriate

Brand: HZZN

Packaging Specifics: Specific in plastic bag and neutral box with label,boxes in fumigated pallets.

Specification Product Number37230-24571Bearing ID (A)30mmMounting Width (C)150mmCenter Line Height (B)seventeen.25mm Packing & Supply To greater make certain the safety of your items, Manufacturing unit injection molded plastic sheave pulley PA 6 MC Nylon PP nylon sheave pulley professional, environmentally pleasant, convenient and productive packaging solutions will be offered. Organization Profile FAQ Refer to samples price , we will revert it to you when we start off our enterprise transaction. Or if you concur to spot us your trialorder now, Expert Producer Sale New Layout .5t 1t 2t 3t 5t Manual Pulley Chain Hoist we can deliver samples in free of charge of charge.

What is a push shaft?

If you observe a clicking sound whilst driving, it is most likely the driveshaft. An experienced vehicle mechanic will be capable to inform you if the noise is coming from each sides or from a single side. If it only takes place on one particular side, you should examine it. If you observe sound on each sides, you ought to speak to a mechanic. In possibly scenario, a alternative driveshaft should be easy to find.

The generate shaft is a mechanical part

A driveshaft is a mechanical gadget that transmits rotation and torque from the engine to the wheels of the automobile. This component is essential to the procedure of any driveline, as the mechanical power from the engine is transmitted to the PTO (energy take-off) shaft, which hydraulically transmits that electricity to linked equipment. Distinct drive shafts incorporate distinct combinations of joints to compensate for modifications in shaft length and angle. Some sorts of travel shafts incorporate connecting shafts, inner continual velocity joints, and external set joints. They also include anti-lock system rings and torsional dampers to stop overloading the axle or leading to the wheels to lock.

Although driveshafts are fairly light-weight, they require to take care of a great deal of torque. Torque used to the drive shaft makes torsional and shear stresses. Due to the fact they have to face up to torque, these shafts are created to be light-weight and have small inertia or excess weight. As a result, they normally have a joint, coupling or rod in between the two parts. Factors can also be bent to accommodate changes in the distance in between them.

The push shaft can be manufactured from a assortment of materials. The most frequent content for these components is metal, even though alloy steels are frequently utilized for substantial-strength applications. Alloy metal, chromium or vanadium are other supplies that can be employed. The kind of content utilised depends on the application and dimension of the ingredient. In a lot of situations, metallic driveshafts are the most sturdy and least expensive choice. Plastic shafts are employed for light duty apps and have distinct torque ranges than steel shafts.

It transfers electricity from the engine to the wheels

A car’s powertrain is made up of an electric powered motor, transmission, and differential. Every section performs a specific work. In a rear-wheel generate motor vehicle, the energy created by the motor is transmitted to the rear tires. This arrangement improves braking and managing. The differential controls how a lot power every wheel receives. The torque of the engine is transferred to the wheels in accordance to its speed.

The transmission transfers electrical power from the motor to the wheels. It is also called “transgender”. Its occupation is to guarantee energy is sent to the wheels. Electrical autos can not push on their own and demand a gearbox to drive ahead. It also controls how considerably energy reaches the wheels at any given minute. The transmission is the very last part of the electrical power transmission chain. Despite its several names, the transmission is the most sophisticated ingredient of a car’s powertrain.

The driveshaft is a lengthy steel tube that transmits mechanical electrical power from the transmission to the wheels. Cardan joints hook up to the push shaft and provide flexible pivot points. The differential assembly is mounted on the generate shaft, permitting the wheels to change at distinct speeds. The differential enables the wheels to change at different speeds and is quite crucial when cornering. Axles are also critical to the efficiency of the car.

It has a rubber boot that safeguards it from dust and moisture

To hold this boot in excellent situation, you need to cleanse it with cold water and a rag. Never ever spot it in the dryer or in direct sunlight. Warmth can deteriorate the rubber and trigger it to shrink or crack. To lengthen the lifestyle of your rubber boots, apply rubber conditioner to them frequently. Indigenous peoples in the Amazon area acquire latex sap from the bark of rubber trees. Then they put their feet on the fireplace to solidify the sap.

it has a U-shaped connector

The travel shaft has a U-joint that transfers rotational vitality from the engine to the axle. Faulty gimbal joints can cause vibrations when the vehicle is in motion. This vibration is frequently mistaken for a wheel balance problem. Wheel balance issues can lead to the automobile to vibrate even though driving, although a U-joint failure can trigger the motor vehicle to vibrate when decelerating and accelerating, and cease when the automobile is stopped.

The drive shaft is related to the transmission and differential employing a U-joint. It enables for modest changes in situation between the two parts. This prevents the differential and transmission from remaining properly aligned. The U-joint also permits the travel shaft to be connected unconstrained, making it possible for the vehicle to go. Its primary function is to transmit electricity. Of all sorts of elastic couplings, U-joints are the oldest.

Your vehicle’s U-joints need to be inspected at least two times a year, and the joints need to be greased. When checking the U-joint, you need to listen to a dull seem when changing gears. A clicking sound signifies inadequate grease in the bearing. If you listen to or truly feel vibrations when shifting gears, you may possibly need to service the bearings to extend their life.

it has a slide-in tube

The telescopic layout is a present day alternative to conventional driveshaft types. This progressive style is based on an unconventional design philosophy that brings together advances in material science and producing procedures. Consequently, they are a lot more productive and lighter than conventional styles. Slide-in tubes are a straightforward and effective layout solution for any car software. Right here are some of its rewards. Read through on to learn why this kind of shaft is ideal for several applications.

The telescopic travel shaft is an important part of the standard automobile transmission technique. These driveshafts let linear movement of the two parts, transmitting torque and rotation throughout the vehicle’s driveline. They also take up power if the vehicle collides. Frequently referred to as foldable driveshafts, their acceptance is directly dependent on the evolution of the automotive business.

It employs a bearing push to replace worn or damaged U-joints

A bearing push is a system that utilizes a rotary push mechanism to install or get rid of worn or ruined U-joints from a drive shaft. With this resource, you can change worn or damaged U-joints in your vehicle with relative ease. The first action involves positioning the drive shaft in the vise. Then, use the 11/16″ socket to push the other cup in significantly sufficient to install the clips. If the cups will not fit, you can use a bearing push to get rid of them and repeat the method. After getting rid of the U-joint, use a grease nipple Make positive the new grease nipple is set up appropriately.

Worn or broken U-joints are a significant source of driveshaft failure. If one of them had been destroyed or broken, the complete driveshaft could dislocate and the vehicle would get rid of energy. Except if you have a skilled mechanic undertaking the repairs, you will have to substitute the total driveshaft. Thankfully, there are several techniques to do this yourself.

If any of these warning signs show up on your vehicle, you ought to take into account changing the ruined or worn U-joint. Common signs of destroyed U-joints consist of rattling or periodic squeaking when transferring, rattling when shifting, wobbling when turning, or rusted oil seals. If you recognize any of these signs, just take your automobile to a certified mechanic for a total inspection. Neglecting to change a worn or destroyed u-joint on the driveshaft can consequence in costly and hazardous repairs and can cause considerable injury to your car.