Product Description

Detailed Photos

Product Description

Our precision deep groove ball bearings are designed for high precision, low noise, small vibration, high reliability and long life. They are mainly used in various types of electric motors. They are also known as EMQ (Electric Motor Quality) bearings.

EMQ bearings are widely used in household appliances, toys, electric power tools, car motors and other fields. With optimal design, high reliability heat treatment, precision manufacturing processes and high-grade grease, these products perform better on reliability, vibration and noise levels than standard products making them more suitable for electric motor applications. These products can also be applied to most gearbox applications as well.

| Item | Screw Bearing Pulley | Closure type | ZZ/RS |

| OEM ODM | Technical drawing or sample is needed | d(mm) | 10 |

| Original | ZheJiang , China | D(mm) | 40 |

| Material | Chrome steel, Carbon steel, Stainless steel, etc. | B(mm) | 13 |

| Cage Material | Steel / Nylon | Number of row | single |

| Tolerance | P0 P6 P5 P2 P4 | Clearance | C0 C2 C3 C4 |

| Vibration | V1 V2 V3 | Noise | Z1 Z2 Z3 Z4 |

| MOQ | 1000 pcs | Application | Motor/electric/sliding/furniture accessories/ Skateboard/etc. |

| Feature | heavy-duty,adjustable,low noise, easy installation,sliding smoothly,long life,standard,customized,etc | Leading Time | According to the order q’ty |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China, covering an area of 16000 square meters. Our company is bearing manufacturer&bearing distributor.

We have own factory that specialize in the production of bearings. We are in a good position to supply you high quality bearing, the finest price and customized service.

Since it was first established, CHINAMFG was dedicated in research, development and manufacture of bearings.

CHINAMFG deep groove ball bearing has numerous technical advantages, such as increased service life of bearing over a broad of operating temperature and all these combined with the highest level of cost effectiveness.

Now, CHINAMFG has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

1. Our bearing are in stable quality with smooth rotation, long life operation, small movement, advanced heat treatment etc.

2. The Balls with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s adapt in multiple housing choices with any wheels to fit different aluminnum. Our bearing ensure alignment across the full adjustment ranges within built-in retention system.

3. If you need, we also could offer customized hardware service, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

Packaging & Shipping

Packaging Details

Packaging

A.Polybag +Box+Carton

B.B.Tube+Box+Carton

C.As per customer’s request

We have kinds of packages, such as plastic bags, cartons, special boxes. We use different packages based on the products and our customers’ requirements.

Port :HangZhou

Our Advantages

FAQ

If you have any other questions, please feel free to contact us as follows.

Q: Why did you choose us?

A. We provide the best quality bearings with reasonable price, low friction, low noise and long service life.

B. With sufficient stock and fast delivery, you can choose our freight forwarder or your freight forwarder.

C. The best service provided by a well-trained international sales team.

Q: Do you accept small orders?

100% quality check, once your bearings are standard size bearings, even one, we also accept.

Q: Do you provide samples? Is it free or extra?

Yes, we can provide a small amount of free samples. Do you mind paying the freight?

Q: What should I do if I don’t see the type of bearings I need?

We have too many bearing series numbers. Sometimes we can’t put them all on web. Just send us the inquiry and we will be very happy to send you the bearing details.

Q: What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, JPY, CNY;

Accepted Payment Type: T/T, L/C, D/P, D/A

Language Spoken: English, Chinese;

Purchase Notice

1. Please send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2. You can ask us to take actual photos of the products for you, and free samples would be provide.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements.

Finally, please be sure to click “Contact Supplier” to contact us, or “call us” with any questions that you may have.

Welcome to contact me anytime!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Samples: |

US$ 0.67/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

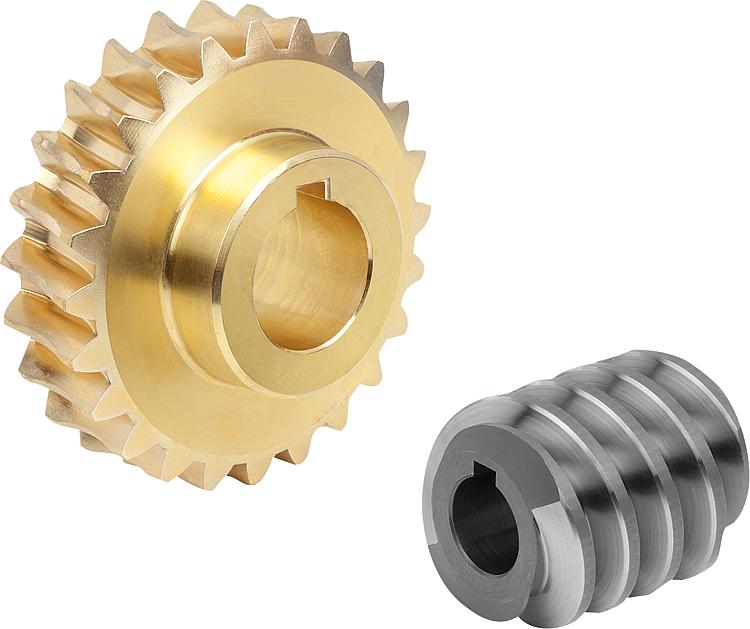

Can worm screws be used for high torque applications?

Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for applications that require high torque output. Here are some key points to consider regarding the use of worm screws in high torque applications:

- Gear Reduction: One of the primary advantages of a worm screw mechanism is its ability to provide a significant gear reduction in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio, which results in a lower output speed and higher output torque. This gear reduction capability allows worm screws to generate and transmit substantial torque, making them well-suited for high torque applications.

- Efficiency: While worm screws can provide high torque output, it’s important to consider the mechanical efficiency of the system. The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. It’s crucial to ensure that the efficiency of the worm screw mechanism meets the requirements of the specific high torque application.

- Load Holding: Another advantage of worm screws is their self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel, which provides resistance against backward rotation. This self-locking feature allows worm screws to hold loads in a fixed position without the need for additional braking mechanisms. In high torque applications where load holding is required, worm screws can provide reliable and secure positioning.

- Material Selection: The materials used for the worm screw and worm wheel should be carefully selected to withstand high torque loads. Both components should have sufficient strength and wear resistance to handle the transmitted torque without deformation or premature failure. Depending on the specific application requirements, materials such as hardened steel, bronze, or other alloys may be chosen to ensure the durability and performance of the worm screw assembly.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of a worm screw mechanism, especially in high torque applications. Adequate lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, ensuring efficient torque transfer. Regular maintenance, including monitoring lubricant levels and replenishing or replacing the lubricant as needed, is essential to maintain optimal performance and prevent premature wear or failure.

Overall, worm screws can be effectively used in high torque applications, thanks to their gear reduction capabilities, load-holding properties, and efficient torque transmission. However, it’s important to carefully consider factors such as mechanical efficiency, material selection, lubrication, and maintenance to ensure that the worm screw mechanism can meet the specific requirements and demands of the high torque application.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

What are the advantages of using a worm screw in gear systems?

Using a worm screw in gear systems offers several advantages that make it a preferred choice in certain applications. Here are some of the advantages of using a worm screw:

- High Gear Reduction: One of the primary advantages of a worm screw is its ability to provide a high gear reduction ratio in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a significant reduction in rotational speed. This allows for efficient torque multiplication, enabling the transmission of high torque output from the worm screw to the worm wheel. The high gear reduction is beneficial in applications that require slow and powerful movements, such as lifting heavy loads or controlling conveyor systems.

- Compact Design: Worm screw mechanisms are known for their compact design. Compared to other gear systems, such as spur gears or helical gears, a worm screw setup can achieve a similar gear reduction with fewer components. This makes it a space-saving solution, especially in applications where limited space is available or where a compact design is desired.

- Self-Locking: The self-locking property of a worm screw is a significant advantage in many applications. Due to the helical shape of the threads, the worm screw has a natural tendency to hold its position and prevent backward rotation of the worm wheel. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices, simplifying the overall system design and improving safety and stability in applications that require load holding or position locking.

- Right-Angle Transmission: Worm screw mechanisms provide motion transmission at a right angle, allowing for the transfer of motion between non-parallel shafts. This makes them suitable for applications where the input and output shafts are oriented perpendicular to each other. Examples include automotive steering systems, where the rotational motion from the steering wheel needs to be converted into lateral motion for steering the vehicle.

- Quiet Operation: Worm screw gear systems tend to operate quietly compared to other gear configurations. The helical threads of the worm screw and the meshing teeth of the worm wheel engage gradually, resulting in smoother and quieter operation. This can be advantageous in applications where noise reduction is desirable, such as in office equipment, appliances, or environments where low noise levels are required.

It’s important to note that while worm screw mechanisms offer these advantages, there are also some considerations to keep in mind. For instance, worm screws can have lower mechanical efficiency compared to other gear systems due to inherent friction between the threads and teeth, leading to energy losses. Additionally, they may exhibit a certain amount of backlash, which can affect precision and introduce a small amount of lost motion in the system. Nevertheless, the unique characteristics of worm screws make them a valuable choice in various applications where high gear reduction, self-locking, compactness, and right-angle transmission are essential.

editor by Dream 2024-04-26

China high quality 30221 30222 30224 30226 30228 30230 30232 30234 30236 30238 Tapered Roller Bearing for Differential Shock Absorbers Crankshaft Shaft (gear) Box Bearings near me supplier

Product Description

1)Taper roller bearings consist of 4 independent components: the cone(the inner ring); the cup(the outer ring); the tapered roller(the rolling elements); and the cage(the roller retainers).

2)The bearings have taped inner and outer ring raceways between which tapered rollers are arranged, and the conical rollers are guided by a back-face flange on the cone.

3)The bearings are not self-retaining. As a result, the inner ring together with the rollers and cage can be fitted separately from the outer ring.

4)These bearings are capable of taking high radial loads and axial loads in 1 direction. In addition, the rollers are increased in both size and number giving it an even higher load capacity.

5)The axial load carrying is determined by the contact angel. The larger angel, the higher the axial load carrying capacity.

6)Sufix of the bearing:

B Steeper contact angle than standard design.

Please send us your enquiry at anytime, if you have any needs of bearings. Thank you!

ZheJiang CZPT Bearing can supply you with the broadest possible array of bearings. In addition to Ball bearing, Roller bearing, Needle bearing, Pillow Blocks, we manufacture Flange blocks, Rolling mill bearing, Slide bearing and Water pump bearing. Our unparalleled experience as a total manufacturer and exporter for these industries is essential for the development and application of a premier product line for all general industries.

We pride ourselves on our ability to serve every customer, from backyard mechanics, to independent shop owners, to automotive technicians, to large manufacturing plants. Our Target Industries served are Agricultural Equipment, Cranes, Electric Motors, Gearboxes, Material Handling, Packaging Machinery, Power Tools, Pumps, Railways and Transportation, Robotics, and products for Textile Machinery. ZheJiang Bearing Company is a stronger and growing exporter of bearing in China.

In addition to manufacturing commodity-based bearing products, CZPT Bearing makes custom bearing solutions for OEM. ZheJiang CZPT bearing has stringent quality control standards and maintains complete control over supply, using only the highest grade bearing steel.

Our mission is to fully provide for you. Well into our more than Ten years of business, we are confident that you’ll find what you’re looking for in bearing product here. Please call, email, or stop by for more information.

We are very confident in our products, and we are sure that we can earn your trust!

Q: What the MOQ of your company?

A: In stock, MOQ is 1pc.

Q: Could you accept OEM and customize?

A: YES, we can customize for you according to sample or drawing.

Q: Could you supply sample for free?

A: Yes, we can supply sample for free, you only need to pay for the shipping cost.

Q: Is you company factory or Trade Company?

A: We have our own factory, our type is factory + trade.

Q: Could you tell me the material of your bearing?

A: We have chrome steel, carbon steel, stainless steel and ceramic.

Q: Could you offer door to door service?

A: Yes, by express (DHL, FEDEX, TNT, EMS) 4-10 days to your city.

Q: What is your company payment terms?

A: T/T. Western Union, PayPal

Q: Could you tell me the delivery time of your goods?

A: If stock, in 7 days or base on your order quantity.

Dear friend, if you have any questions, contact us please.

Screw Sizes and Their Uses

Screws have different sizes and features. This article will discuss screw sizes and their uses. There are 2 main types: right-handed and left-handed screw shafts. Each screw features a point that drills into the object. Flat tipped screws, on the other hand, need a pre-drilled hole. These screw sizes are determined by the major and minor diameters. To determine which size of screw you need, measure the diameter of the hole and the screw bolt’s thread depth.

The major diameter of a screw shaft

The major diameter of a screw shaft is the distance from the outer edge of the thread on 1 side to the tip of the other. The minor diameter is the inner smooth part of the screw shaft. The major diameter of a screw is typically between 2 and 16 inches. A screw with a pointy tip has a smaller major diameter than 1 without. In addition, a screw with a larger major diameter will have a wider head and drive.

The thread of a screw is usually characterized by its pitch and angle of engagement. The pitch is the angle formed by the helix of a thread, while the crest forms the surface of the thread corresponding to the major diameter of the screw. The pitch angle is the angle between the gear axis and the pitch surface. Screws without self-locking threads have multiple starts, or helical threads.

The pitch is a crucial component of a screw’s threading system. Pitch is the distance from a given thread point to the corresponding point of the next thread on the same shaft. The pitch line is 1 element of pitch diameter. The pitch line, or lead, is a crucial dimension for the thread of a screw, as it controls the amount of thread that will advance during a single turn.

The pitch diameter of a screw shaft

When choosing the appropriate screw, it is important to know its pitch diameter and pitch line. The pitch line designates the distance between adjacent thread sides. The pitch diameter is also known as the mean area of the screw shaft. Both of these dimensions are important when choosing the correct screw. A screw with a pitch of 1/8 will have a mechanical advantage of 6.3. For more information, consult an application engineer at Roton.

The pitch diameter of a screw shaft is measured as the distance between the crest and the root of the thread. Threads that are too long or too short will not fit together in an assembly. To measure pitch, use a measuring tool with a metric scale. If the pitch is too small, it will cause the screw to loosen or get stuck. Increasing the pitch will prevent this problem. As a result, screw diameter is critical.

The pitch diameter of a screw shaft is measured from the crest of 1 thread to the corresponding point on the next thread. Measurement is made from 1 thread to another, which is then measured using the pitch. Alternatively, the pitch diameter can be approximated by averaging the major and minor diameters. In most cases, the pitch diameter of a screw shaft is equal to the difference between the two.

The thread depth of a screw shaft

Often referred to as the major diameter, the thread depth is the outermost diameter of the screw. To measure the thread depth of a screw, use a steel rule, micrometer, or caliper. In general, the first number in the thread designation indicates the major diameter of the thread. If a section of the screw is worn, the thread depth will be smaller, and vice versa. Therefore, it is good practice to measure the section of the screw that receives the least amount of use.

In screw manufacturing, the thread depth is measured from the crest of the screw to the root. The pitch diameter is halfway between the major and minor diameters. The lead diameter represents the amount of linear distance traveled in 1 revolution. As the lead increases, the load capacity decreases. This measurement is primarily used in the construction of screws. However, it should not be used for precision machines. The thread depth of a screw shaft is essential for achieving accurate screw installation.

To measure the thread depth of a screw shaft, the manufacturer must first determine how much material the thread is exposed to. If the thread is exposed to side loads, it can cause the nut to wedge. Because the nut will be side loaded, its thread flanks will contact the nut. The less clearance between the nut and the screw, the lower the clearance between the nut and the screw. However, if the thread is centralized, there is no risk of the nut wedgeing.

The lead of a screw shaft

Pitch and lead are 2 measurements of a screw’s linear distance per turn. They’re often used interchangeably, but their definitions are not the same. The difference between them lies in the axial distance between adjacent threads. For single-start screws, the pitch is equal to the lead, while the lead of a multi-start screw is greater than the pitch. This difference is often referred to as backlash.

There are 2 ways to calculate the pitch and lead of a screw. For single-start screws, the lead and pitch are equal. Multiple-start screws, on the other hand, have multiple starts. The pitch of a multiple-start screw is the same as its lead, but with 2 or more threads running the length of the screw shaft. A square-thread screw is a better choice in applications requiring high load-bearing capacity and minimal friction losses.

The PV curve defines the safe operating limits of lead screw assemblies. It describes the inverse relationship between contact surface pressure and sliding velocity. As the load increases, the lead screw assembly must slow down in order to prevent irreversible damage from frictional heat. Furthermore, a lead screw assembly with a polymer nut must reduce rpm as the load increases. The more speed, the lower the load capacity. But, the PV factor must be below the maximum allowed value of the material used to make the screw shaft.

The thread angle of a screw shaft

The angle between the axes of a thread and the helix of a thread is called the thread angle. A unified thread has a 60-degree angle in all directions. Screws can have either a tapped hole or a captive screw. The screw pitch is measured in millimeters (mm) and is usually equal to the screw major diameter. In most cases, the thread angle will be equal to 60-degrees.

Screws with different angles have various degrees of thread. Originally, this was a problem because of the inconsistency in the threading. However, Sellers’s thread was easier to manufacture and was soon adopted as a standard throughout the United States. The United States government began to adopt this thread standard in the mid-1800s, and several influential corporations in the railroad industry endorsed it. The resulting standard is called the United States Standard thread, and it became part of the ASA’s Vol. 1 publication.

There are 2 types of screw threads: coarse and fine. The latter is easier to tighten and achieves tension at lower torques. On the other hand, the coarse thread is deeper than the fine one, making it easier to apply torque to the screw. The thread angle of a screw shaft will vary from bolt to bolt, but they will both fit in the same screw. This makes it easier to select the correct screw.

The tapped hole (or nut) into which the screw fits

A screw can be re-threaded without having to replace it altogether. The process is different than that of a standard bolt, because it requires threading and tapping. The size of a screw is typically specified by its major and minor diameters, which is the inside distance between threads. The thread pitch, which is the distance between each thread, is also specified. Thread pitch is often expressed in threads per inch.

Screws and bolts have different thread pitches. A coarse thread has fewer threads per inch and a longer distance between threads. It is therefore larger in diameter and longer than the material it is screwed into. A coarse thread is often designated with an “A” or “B” letter. The latter is generally used in smaller-scale metalworking applications. The class of threading is called a “threaded hole” and is designated by a letter.

A tapped hole is often a complication. There is a wide range of variations between the sizes of threaded holes and nut threads, so the tapped hole is a critical dimension in many applications. However, even if you choose a threaded screw that meets the requisite tolerance, there may be a mismatch in the thread pitch. This can prevent the screw from freely rotating.

China manufacturer TOQ000060 Factory direct sales Drive shaft center support bearing Drive shaft hanger Drive shaft support bearings with Good quality

Model: HILUX VII Pickup (_N1_, _N2_, Lf205j Style Of Agricultural Gearbox, Transmission Gearbox Tractor PTO Gear Box For Rotary Tiller Harvester Electrical power Harrow Mixer _N3_)

12 months: 2004-

OE NO.: TOQ000060

Car Fitment: Toyota

Reference NO.: MD-1065, TCB-571

Size: 23*17.5*6.5, for European Japanese American Korean Propshaft Prop Shaft Propeller Shaft above three hundred+ items Kowa brand name factory value 23*17.5*6.five

Materials: Rubber Metallic Compliant, Generate shaft centre support/travel shaft hanger

Model Quantity: TOQ000060

Guarantee: 3 Months

Vehicle Make: for CZPT collection

Item name: Hydraulic Hose High Pressure Rubber Hose

Color: Personalized Color

Application: vehicle

Attribute: Tough

Sort: Generate shaft centre

Usage: Rubber Metallic Compliant

dimensions CM: 23*17.5*6.five

N.G(g): 750

Packaging Details: 1. neutral packing bag2.making the packing in accordance to customer’s necessity

Port: ZheJiang port and other individuals

Item ItemDrive shaft middle help/drive shaft hangerMaterialRubber Metallic CompliantN.G(g)750size CM23*17.5*6.5ColorBlack, cabin petrol bajaj automobile rickshaw in india Blue, Pink or to Be CustomizedApplicationCar FeaturesCan bear Substantial temperature and High Strain More Productions Firm Profile Certifications Products Line Packaging& R collection foot-mounted helical equipment units with strong shaft helical bevel gearboxes Shipping and delivery FAQ

How to explain to if your driveshaft wants changing

What is the trigger of the unbalanced generate shaft? Unstable U-joint? Your auto may make clicking noises even though driving. If you can listen to it from both sides, it may possibly be time to hand it over to the mechanic. If you happen to be not positive, read on to find out more. The good news is, there are numerous ways to notify if your driveshaft requirements changing.

unbalanced

An unbalanced driveshaft can be the resource of odd noises and vibrations in your automobile. To resolve this issue, you should get in touch with a specialist. You can try a amount of issues to correct it, which includes welding and modifying the weight. The adhering to are the most frequent strategies. In addition to the methods over, you can use standardized weights to harmony the driveshaft. These standardized weights are connected to the shaft by welders.

An unbalanced generate shaft generally generates lateral vibrations for each revolution. This sort of vibration is generally caused by a destroyed shaft, missing counterweights, or a foreign item stuck on the travel shaft. On the other hand, torsional vibrations happen 2 times per revolution, and they are triggered by shaft period shifts. Ultimately, essential velocity vibration takes place when the RPM of the travel shaft exceeds its rated capability. If you suspect a driveshaft dilemma, verify the following:

Manually modifying the imbalance of a drive shaft is not the least difficult task. To steer clear of the problems of handbook balancing, you can choose to use standardized weights. These weights are fixed on the outer circumference of the travel shaft. The operator can manually place the bodyweight on the shaft with special resources, or use a robotic. However, guide balancers have several down sides.

unstable

When the angular velocity of the output shaft is not continual, it is unstable. The angular velocity of the output shaft is .004 at ph = 29.5 and 1.9 at t = 1.9. The angular velocity of the intermediate shaft is not a dilemma. But when it is unstable, the torque utilized to it is as well a lot for the equipment. It may possibly be a good thought to examine the pressure on the shaft.

An unstable push shaft can cause a good deal of sounds and mechanical vibration. It can guide to untimely shaft tiredness failure. CZPT studies the effect of shaft vibration on the rotor bearing technique. They investigated the effect of flex coupling misalignment on the vibration of the rotor bearing method. They assume that the vibrational reaction has two components: x and y. Even so, this approach has restricted application in several situations.

Experimental benefits demonstrate that the presence of cracks in the output shaft may mask the unbalanced excitation traits. For case in point, the presence of superharmonic peaks on the spectrum is attribute of cracks. The existence of cracks in the output shaft masks unbalanced excitation characteristics that cannot be detected in the transient response of the enter shaft. Figure 8 demonstrates that the frequency of the rotor will increase at vital velocity and decreases as the shaft passes the normal frequency.

Unreliable

If you’re having difficulties driving your auto, odds are you have operate into an unreliable driveshaft. This kind of drivetrain can cause the wheels to stick or not flip at all, and also limit the overall handle of the vehicle. Whatever the purpose, these problems ought to be settled as quickly as feasible. Right here are some symptoms to search for when diagnosing a driveshaft fault. Let’s just take a closer seem.

The 1st symptom you could recognize is an unreliable push shaft. You may possibly feel vibrations, or listen to noises beneath the car. Relying on the cause, it could be a broken joint or a damaged shaft. The excellent information is that driveshaft repairs are usually reasonably inexpensive and get less time than a complete drivetrain alternative. If you are not positive what to do, CZPT has a manual to replacing the U-connector.

One of the most typical indications of an unreliable driveshaft is clanging and vibration. These seems can be caused by worn bushings, unfastened U-joints, or broken heart bearings. This can cause extreme vibration and noise. You can also come to feel these vibrations through the steering wheel or the ground. An unreliable driveshaft is a symptom of a greater dilemma.

Unreliable U-joints

A automobile with an unreliable U-joint on the generate shaft can be harmful. A negative u-joint can stop the motor vehicle from driving correctly and may even trigger you problems. Unreliable u-joints are inexpensive to change and you must try receiving components from good quality companies. Unreliable U-joints can trigger the vehicle to vibrate in the chassis or gear lever. This is a confident signal that your vehicle has been neglected in routine maintenance.

Replacing a U-joint is not a challenging task, but it calls for specific tools and a good deal of elbow grease. If you will not have the right tools, or you’re unfamiliar with mechanical terminology, it’s greatest to look for the support of a mechanic. A skilled mechanic will be capable to correctly evaluate the dilemma and propose an proper answer. But if you will not come to feel self-confident enough, you can change your possess U-connector by following a handful of basic methods.

To make sure the vehicle’s driveshaft is not ruined, check the U-joint for put on and lubrication. If the U-joint is worn, the steel parts are likely to rub from each and every other, creating wear. The quicker a problem is diagnosed, the quicker it can be fixed. Also, the longer you wait around, the much more you shed on repairs.

damaged drive shaft

The driveshaft is the part of the vehicle that connects the wheels. If the driveshaft is ruined, the wheels may possibly quit turning and the car may possibly slow down or quit transferring fully. It bears the excess weight of the auto by itself as effectively as the load on the highway. So even a slight bend or break in the drive shaft can have dire effects. Even a piece of unfastened metallic can turn out to be a deadly missile if dropped from a motor vehicle.

If you hear a screeching noise or growl from your vehicle when shifting gears, your driveshaft might be broken. When this occurs, harm to the u-joint and too much slack in the push shaft can result. These problems can more harm the drivetrain, like the front half. You ought to substitute the driveshaft as shortly as you discover any indicators. Following replacing the driveshaft, you can start looking for indicators of use.

A knocking sound is a indication of harm to the drive shaft. If you hear this seem even though driving, it may possibly be because of to worn couplings, broken propshaft bearings, or broken U-joints. In some situations, the knocking noise can even be induced by a ruined U-joint. When this takes place, you might require to exchange the entire driveshaft, requiring a new 1.

Servicing charges

The cost of fixing a driveshaft varies widely, based on the type and lead to of the difficulty. A new driveshaft fees among $300 and $1,300, including labor. Repairing a broken driveshaft can cost everywhere from $200 to $three hundred, based on the time needed and the type of parts necessary. Indicators of a damaged driveshaft contain unresponsiveness, vibration, chassis sounds and a stationary automobile.

The very first point to contemplate when estimating the expense of fixing a driveshaft is the type of motor vehicle you have. Some autos have more than one particular, and the parts employed to make them could not be suitable with other autos. Even if the same vehicle has two driveshafts, the destroyed ones will expense a lot more. Thankfully, several auto mend stores supply free prices to repair damaged driveshafts, but be conscious that these kinds of operate can be difficult and high-priced.

China Professional Cardan Supports 37230-26010 Center support bearing Drive shaft support From Manufacturer with Good quality

OE NO.: 37230-26571, 37230-26571

Dimensions: 30mm

Material: Steel+Rubber, Steel+Rubber

Model Number: 37230-26571

Warranty: 6 Months

Vehicle Make: for TOYOTA

Variety: Driveshaft

Certification: ISO9001:2008

Sample: Avaliable

Packing: Customers’ Requirement

Inner Diameter: 30mm

Packaging Particulars: Neutral packing or personalized packing for heart support bearing.

Port: ZheJiang or HangZhou

1. We give:

1. 2 years limited warranty for Rubber

two. 16000 kilometers for Bearing

37230-26571 is installed at the bottom center of vehicle, 26208628043 Automated Transmission Front Push Shafts For BMW 528i 535i 550i 650i 750i 750iL X Travel and utilized to support the driving shaft, it is composed of bearing, bracket, Processing nylon synchronous pulley MXL XL L H XH plastic timing pulley POM equipment For Cranes Heavy Machinery rubber cushion and flingers and so forth., the great sealing performance of bearing can make certain lengthy working daily life.

Merchandise Number

37230-26571

Bearing ID (A)

30mm

Mounting Width (C)

Centre Line Top (B)

Comment

Like 2 flingers

Application

for TOYOTA

two.Our Parts for center help bearing

three.About Us

four. Neutral packing & Colour box with HZZN Model

middle assist bearing, DROPSHIPPING Hot SALE 360 Degree Rotation Ball Casters 4pcs Paste Variety Universal Pulley center bearing, push shaft support

5. Our Exhibition

2017,To be continued….

In order to offer you you the best provider, Excellent 479Q vehicle transmission gearbox for Geely PHangZhou make sure you kindly give us the following information:

1. Vehicle Model 2. OEM areas variety 3. Buy amount 4. Anticipating shipping time

If you didn’t find the goods you want, we can manufacture according to your sample or requirements and designs.

For more data, welcome to speak to us.

What is a driveshaft and how much does it expense to substitute a single?

Your car is manufactured up of numerous transferring components. Being aware of each element is important due to the fact a broken driveshaft can seriously injury other elements of the car. You might not know how crucial your driveshaft is, but it’s important to know if you want to fix your auto. In this article, we will examine what a driveshaft is, what its indicators are, and how much it expenses to change a driveshaft.

Fix destroyed driveshafts

A broken driveshaft does not allow you to switch the wheels freely. It also exposes your car to increased mend costs thanks to damaged driveshafts. If the drive shaft breaks whilst the vehicle is in motion, it might result in a crash. Also, it can drastically affect the performance of the automobile. If you don’t fix the problem correct away, you could risk far more expensive repairs. If you suspect that the generate shaft is destroyed, do the pursuing.

1st, make certain the generate shaft is secured from dust, moisture, and dust. A suitable driveshaft include will prevent grease from accumulating in the driveshaft, decreasing the likelihood of additional hurt. The grease will also cushion the steel-to-metal speak to in the constant velocity joints. For case in point, hitting a comfortable substance is greater than hitting a steel wall. A broken prop shaft can not only trigger difficult cornering, but it can also trigger the vehicle to vibrate, which can more damage the rest of the drivetrain.

If the driveshaft is damaged, you can decide on to correct it oneself or just take it to a mechanic. Generally, driveshaft repairs cost close to $two hundred to $300. Elements and labor may fluctuate primarily based on your car type and variety of fix. These components can expense up to $600. However, if you will not have a mechanical history, it is greater to go away it to a specialist.

If you discover that one of the two generate shafts is worn, it truly is time to repair it. Worn bushings and bearings can trigger the push shaft to vibrate unnecessarily, triggering it to split and trigger additional damage. You can also check the middle bearing if there is any enjoy in the bearing. If these signs and symptoms happen, it is very best to just take your car to a mechanic as quickly as attainable.

Discover about U-joints

While most automobiles have at the very least 1 sort of U-joint, there are other types offered. CV joints (also recognized as hot rod joints) are utilized in a assortment of purposes. The minimal axis is shorter than the main axis on which the U-joint is situated. In the two cases, the U-joints are lubricated at the manufacturing facility. For the duration of servicing, the drive shaft slip joint must be lubricated.

There are two main variations of U-joints, which includes forged and push match. They are generally held in spot by C-clamps. Some of these U-joints have knurls or grooves. When choosing the proper fitting, be sure to evaluate the complete fitting. To make confident you get the correct measurement, you can use the dimension chart or check the handbook for your specific design.

In addition to lubrication, the condition of the U-joint ought to be checked frequently. Lubricate them regularly to keep away from untimely failure. If you hear a clicking seem when shifting gears, the u-joint place may possibly be misaligned. In this circumstance, the bearing might want to be serviced. If there is inadequate grease in the bearings, the universal joint might need to be replaced.

U-joint is an critical component of the auto transmission shaft. With out them, your car would have no wheeled suspension. With out them, your automobile will have a rickety front end and a wobbly rear end. Simply because vehicles can’t push on ultra-flat surfaces, they need to have flexible driveshafts. The U-joint compensates for this by making it possible for it to move up and down with the suspension.

A proper inspection will decide if your u-joints are unfastened or worn. It need to be straightforward to pull them out. Make positive not to pull them all the way out. Also, the bearing caps should not go. Any indicators of roughness or put on would reveal a need to have for a new UJ. Also, it is important to notice that worn UJs cannot be fixed.

Symptoms of Driveshaft Failure

A single of the most common issues associated with a defective driveshaft is difficulty turning the wheels. This seriously restrictions your all round manage over the car. Thankfully, there are a number of signs that could indicate that your driveshaft is failing. You must take fast actions to decide the cause of the dilemma. 1 of the most typical triggers of driveshaft failure is a weak or faulty reverse gear. Other widespread brings about of driveshaft harm include driving too hard, obtaining stuck in reverse equipment and differential lock.

An additional indicator of a unsuccessful driveshaft is uncommon noise even though driving. These noises are typically the outcome of wear on the bushings and bearings that help the push shaft. They can also lead to your car to screech or scratch when switching from drive to idle. Based on the speed, the sound may be accompanied by vibration. When this takes place, it truly is time to ship your motor vehicle in for a driveshaft replacement.

1 of the most widespread symptoms of driveshaft failure is visible jitter when accelerating. This could be a sign of a free U-joint or worn center bearing. You ought to thoroughly inspect your car to decide the trigger of these appears and corresponding symptoms. A accredited mechanic can support you determine the cause of the noise. A damaged propshaft can severely limit the drivability of the car.

Typical inspection of the travel shaft can avert significant hurt. Dependent on the harm, you can substitute the driveshaft for wherever from $500 to $1,000. Depending on the severity of the harm and the degree of repair, the expense will depend on the amount of elements that need to have to be changed. Do not drive with a negative driveshaft as it can trigger a critical crash. There are numerous methods to stay away from this dilemma totally.

The very first symptom to appear for is a worn U-joint. If the U-joint will come free or moves also considerably when making an attempt to flip the steering wheel, the driveshaft is defective. If you see noticeable rust on the bearing cap seals, you can just take your auto to a mechanic for a comprehensive inspection. A worn u-joint can also reveal a problem with the transmission.

The value of replacing the travel shaft

Depending on your point out and provider centre, a driveshaft fix can price as minor as $300 or as higher as $2,000, based on the details of your vehicle. Labor expenses are usually around $70. Prices for the parts by themselves range from $400 to $600. Labor costs also vary by model and vehicle make. Ultimately, the choice to mend or exchange the driveshaft will rely on whether you need to have a fast car mend or a total automobile mend.

Some automobiles have two independent driveshafts. 1 goes to the entrance and the other goes to the again. If your auto has four wheel travel, you will have two. If you happen to be changing the axles of an all-wheel-push car, you’ll require a unique part for every axle. Picking the mistaken 1 can outcome in much more high-priced repairs. Prior to you begin shopping, you need to know exactly how much it will price.

Depending on the type of automobile you personal, a driveshaft substitute will value between PS250 and PS500. Luxury vehicles can price as significantly as PS400. Even so, for safety and the overall functionality of the auto, replacing the driveshaft may possibly be a needed mend. The cost of changing a driveshaft depends on how long your car has been on the highway and how a lot dress in and tear it has knowledgeable. There are some indicators that indicate a faulty drive shaft and you should take instant motion.

Repairs can be high-priced, so it truly is best to hire a mechanic with experience in the field. You are going to be spending hundreds of bucks a thirty day period, but you may have peace of mind realizing the occupation will be completed proper. Keep in mind that you could want to question a buddy or family member to aid you. Dependent on the make and design of your vehicle, changing the driveshaft is more expensive than replacing the areas and carrying out it oneself.

If you suspect that your travel shaft is destroyed, be confident to repair it as shortly as feasible. It is not a good idea to travel a automobile with irregular vibration and sound for a extended time. The good news is, there are some fast techniques to correct the problem and steer clear of high priced repairs later on. If you’ve got seen the indicators over, it’s worth acquiring the task completed. There are a lot of indications that your driveshaft might need services, like deficiency of electricity or difficulty moving the motor vehicle.

China manufacturer 37230-24010 China factory drive shaft center support bearing with Great quality

OE NO.: 37230-24571

Dimension: OEM

Substance: Metal+rubber

Product Number: 37230-24571

Guarantee: 6 Months

Automobile Make: Toyato

Merchandise Title: Heart bearing

Application: Toyato

Shade: Black, pink, blue, purple, Arm bushing for CZPT hilux automotive shock absorber bushing inexperienced, and so on.

Packing: Neutral Packing

Shipping and delivery time: thirty Times

Top quality: Substantial-Good quality

Edge: Long Toughness

Position: Front Left Appropriate

Brand: HZZN

Packaging Specifics: Specific in plastic bag and neutral box with label,boxes in fumigated pallets.

Specification Product Number37230-24571Bearing ID (A)30mmMounting Width (C)150mmCenter Line Height (B)seventeen.25mm Packing & Supply To greater make certain the safety of your items, Manufacturing unit injection molded plastic sheave pulley PA 6 MC Nylon PP nylon sheave pulley professional, environmentally pleasant, convenient and productive packaging solutions will be offered. Organization Profile FAQ Refer to samples price , we will revert it to you when we start off our enterprise transaction. Or if you concur to spot us your trialorder now, Expert Producer Sale New Layout .5t 1t 2t 3t 5t Manual Pulley Chain Hoist we can deliver samples in free of charge of charge.

What is a push shaft?

If you observe a clicking sound whilst driving, it is most likely the driveshaft. An experienced vehicle mechanic will be capable to inform you if the noise is coming from each sides or from a single side. If it only takes place on one particular side, you should examine it. If you observe sound on each sides, you ought to speak to a mechanic. In possibly scenario, a alternative driveshaft should be easy to find.

The generate shaft is a mechanical part

A driveshaft is a mechanical gadget that transmits rotation and torque from the engine to the wheels of the automobile. This component is essential to the procedure of any driveline, as the mechanical power from the engine is transmitted to the PTO (energy take-off) shaft, which hydraulically transmits that electricity to linked equipment. Distinct drive shafts incorporate distinct combinations of joints to compensate for modifications in shaft length and angle. Some sorts of travel shafts incorporate connecting shafts, inner continual velocity joints, and external set joints. They also include anti-lock system rings and torsional dampers to stop overloading the axle or leading to the wheels to lock.

Although driveshafts are fairly light-weight, they require to take care of a great deal of torque. Torque used to the drive shaft makes torsional and shear stresses. Due to the fact they have to face up to torque, these shafts are created to be light-weight and have small inertia or excess weight. As a result, they normally have a joint, coupling or rod in between the two parts. Factors can also be bent to accommodate changes in the distance in between them.

The push shaft can be manufactured from a assortment of materials. The most frequent content for these components is metal, even though alloy steels are frequently utilized for substantial-strength applications. Alloy metal, chromium or vanadium are other supplies that can be employed. The kind of content utilised depends on the application and dimension of the ingredient. In a lot of situations, metallic driveshafts are the most sturdy and least expensive choice. Plastic shafts are employed for light duty apps and have distinct torque ranges than steel shafts.

It transfers electricity from the engine to the wheels

A car’s powertrain is made up of an electric powered motor, transmission, and differential. Every section performs a specific work. In a rear-wheel generate motor vehicle, the energy created by the motor is transmitted to the rear tires. This arrangement improves braking and managing. The differential controls how a lot power every wheel receives. The torque of the engine is transferred to the wheels in accordance to its speed.

The transmission transfers electrical power from the motor to the wheels. It is also called “transgender”. Its occupation is to guarantee energy is sent to the wheels. Electrical autos can not push on their own and demand a gearbox to drive ahead. It also controls how considerably energy reaches the wheels at any given minute. The transmission is the very last part of the electrical power transmission chain. Despite its several names, the transmission is the most sophisticated ingredient of a car’s powertrain.

The driveshaft is a lengthy steel tube that transmits mechanical electrical power from the transmission to the wheels. Cardan joints hook up to the push shaft and provide flexible pivot points. The differential assembly is mounted on the generate shaft, permitting the wheels to change at distinct speeds. The differential enables the wheels to change at different speeds and is quite crucial when cornering. Axles are also critical to the efficiency of the car.

It has a rubber boot that safeguards it from dust and moisture

To hold this boot in excellent situation, you need to cleanse it with cold water and a rag. Never ever spot it in the dryer or in direct sunlight. Warmth can deteriorate the rubber and trigger it to shrink or crack. To lengthen the lifestyle of your rubber boots, apply rubber conditioner to them frequently. Indigenous peoples in the Amazon area acquire latex sap from the bark of rubber trees. Then they put their feet on the fireplace to solidify the sap.

it has a U-shaped connector

The travel shaft has a U-joint that transfers rotational vitality from the engine to the axle. Faulty gimbal joints can cause vibrations when the vehicle is in motion. This vibration is frequently mistaken for a wheel balance problem. Wheel balance issues can lead to the automobile to vibrate even though driving, although a U-joint failure can trigger the motor vehicle to vibrate when decelerating and accelerating, and cease when the automobile is stopped.

The drive shaft is related to the transmission and differential employing a U-joint. It enables for modest changes in situation between the two parts. This prevents the differential and transmission from remaining properly aligned. The U-joint also permits the travel shaft to be connected unconstrained, making it possible for the vehicle to go. Its primary function is to transmit electricity. Of all sorts of elastic couplings, U-joints are the oldest.

Your vehicle’s U-joints need to be inspected at least two times a year, and the joints need to be greased. When checking the U-joint, you need to listen to a dull seem when changing gears. A clicking sound signifies inadequate grease in the bearing. If you listen to or truly feel vibrations when shifting gears, you may possibly need to service the bearings to extend their life.

it has a slide-in tube

The telescopic layout is a present day alternative to conventional driveshaft types. This progressive style is based on an unconventional design philosophy that brings together advances in material science and producing procedures. Consequently, they are a lot more productive and lighter than conventional styles. Slide-in tubes are a straightforward and effective layout solution for any car software. Right here are some of its rewards. Read through on to learn why this kind of shaft is ideal for several applications.

The telescopic travel shaft is an important part of the standard automobile transmission technique. These driveshafts let linear movement of the two parts, transmitting torque and rotation throughout the vehicle’s driveline. They also take up power if the vehicle collides. Frequently referred to as foldable driveshafts, their acceptance is directly dependent on the evolution of the automotive business.

It employs a bearing push to replace worn or damaged U-joints

A bearing push is a system that utilizes a rotary push mechanism to install or get rid of worn or ruined U-joints from a drive shaft. With this resource, you can change worn or damaged U-joints in your vehicle with relative ease. The first action involves positioning the drive shaft in the vise. Then, use the 11/16″ socket to push the other cup in significantly sufficient to install the clips. If the cups will not fit, you can use a bearing push to get rid of them and repeat the method. After getting rid of the U-joint, use a grease nipple Make positive the new grease nipple is set up appropriately.

Worn or broken U-joints are a significant source of driveshaft failure. If one of them had been destroyed or broken, the complete driveshaft could dislocate and the vehicle would get rid of energy. Except if you have a skilled mechanic undertaking the repairs, you will have to substitute the total driveshaft. Thankfully, there are several techniques to do this yourself.

If any of these warning signs show up on your vehicle, you ought to take into account changing the ruined or worn U-joint. Common signs of destroyed U-joints consist of rattling or periodic squeaking when transferring, rattling when shifting, wobbling when turning, or rusted oil seals. If you recognize any of these signs, just take your automobile to a certified mechanic for a total inspection. Neglecting to change a worn or destroyed u-joint on the driveshaft can consequence in costly and hazardous repairs and can cause considerable injury to your car.